This standard regulates the control of batch and continuous pasteurization processes in the US. Our VAT system is supplied on the majority of batch processors used to pasteurize dairy products. For HTST and other continuous pasteurizers, customers rely on our failsafe controls ...

The Anderson-Negele Paperless Process Recorder (PPR), combined with Legendary™ cloud software, offers a cutting-edge solution for streamlining

process data recording, creating and reviewing legal records, and securely storing them for state and third-party audits. M-b issued.

Cloud-based software connected to PPRs. With Legendary™, you can store, review, and approve digital PPR records. It is PMO-compliant.

Discover the AV-9900 HTST Recorder Controller for precise pasteurization control. Four-color charts, PMO compliance, and multi-variable recording in one unit. M-b issued.

Differential pressure switch for use on pasteurization systems. M-b issued

Vat Pasteurization Electronic Controls Package replaces traditional mercury-in-glass thermometers and complies with the Pasteurized Milk Ordinance (PMO) and 3-A Sanitary Standards. M-b issued.

Digital indicating reference thermometer for pasteurization and retort applications- M-b issued.

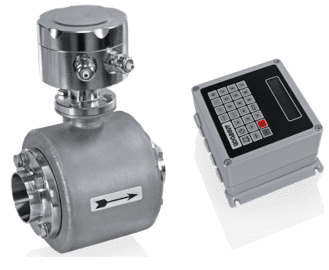

The IZMS series electromagnetic flow meter is PMO M-b approved and an ideal solution for measuring conductive fluids and slurries, including those used in the dairy industry.

The FDA Pasteurized Milk Ordinance (PMO) regulates the control of all batch as well as the more common continuous pasteurization processes in the US. For over 30 years Anderson has been the leading developer and supplier of pasteurization controls for every specific application outlined in the PMO. Our VAT system is supplied on the majority of batch processors used to pasteurize dairy products like ice cream mix, specialty cheeses and yogurts, and seasonal products such as egg nog. For HTST and other continuous pasteurizers, customers rely on our failsafe controls including the DART as their reference thermometer, GB Differential Pressure Switch for regenerator protection, and AV9900 for final control of temperature and flowrate to ensure compliance and a safe product.

PPR (Paperless Process Recorder) is a digital chart recorder system that can be used in pasteurization, CIP, COP, raw silo monitoring and in general any application that requires monitoring of process parameters like temperature, flow, pressure, level, conductivity, turbidity etc.

Legendary™ is a cloud-based software that securely stores records from all PPRs of your plant in a single location. It allows you to conveniently access, review and approve those records remotely from your office desk or home office using any web-enabled device all while meeting PMO compliance.

The combination of PPR hardware and Legendary™ Software forms a next generation paperless chart recorder system. This PMO compliant Digital Process Monitoring technology makes your digital transformation easy.

Copyright © 2022 Anderson-Negele