Our products can be found at work throughout the food, aggregate, plastics, power, chemical and biotech industries, in virtually every type of vessel. Kistler-Morse® products are built tough to withstand the most rugged applications while providing companies with the accuracy they need.

Bolt-on strain gauge sensors for vessels with metal substructures and skirted silos

Bolt-on dual-axis shear force sensors for all types of vessels with metal supports and skirted silos

The Sanitary Specialist: Dynamic content measurement through precise weight measurement, polished design for all hygienic applications

The Allrounder: Dynamic content monitoring through precise weight measurement, for all industrial applications

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement, extremely robust design with cage

High precision process pressure measurement in pipes & hydrostatic level and volume measurement in vessels

The fully integrated all-in-one weighing system for all types of large containers and silos

High Performance Weight Indicator with weight readout on a local display. It can connect to the KM ORB system or feed into a larger configuration.

Multi-Vessel Weight Indicator with Local Display that can monitor up to four separate vessels, consolidating the vessel signals into one single location.

Kistler-Morse® products are utilized in various industries such as food, aggregate, plastics, power, chemical, and biotech. These products are designed to work in almost any type of vessel and are constructed to withstand even the toughest of conditions. Kistler-Morse® products are known for their precision and accuracy, making them an essential tool for many companies.Kistler-Morse® is an Anderson-Negele brand.

With its Kistler-Morse® brand, Anderson-Negele provides total weighing systems for bulk and in-process applications.

Sensors: Our weighing sensors can transform vessels into scales and are suitable for a wide range of environments, from clean, sanitary settings to harsh, outdoor conditions. The Kistler-Morse range includes various types of sensors, including bolt-on sensors, load stands, and load discs.

Controllers: We provide both single and multi-vessel weighing controllers, enabling our customers to keep track of and maintain stable and precise readings.

Inventory Management Solutions: Our inventory management solutions for dry-bulk materials allow for real-time data collection and transmission via the Internet, providing our customers with a dependable method for monitoring and managing their materials.

Kistler-Morse® was established in 1974 by Walter P. Kistler and Charles H. Morse in Bellevue, Washington. Mr. Kistler designed a quartz pressure gage, which would come to be known as the Microcell® Bolt-On Sensor. Due to its dedication to research and development, Kistler-Morse® has engineered some of the industry’s most influential weighing solutions. In 1997, Kistler-Morse® was purchased by Danaher Corporation and moved to Spartanburg, South Carolina shortly after. Today, Kistler-Morse is an Anderson-Negele brand and subsidiary of Fortive Corporation.

In today’s business landscape, it is crucial to have a comprehensive understanding of your inventory, right down to the last unit, in order to achieve optimal efficiency. Such efficiencies can lead to cost savings and a more productive workflow. However, measuring bulk inventory can pose challenges due to its size and the difficult conditions of the tanks. Fortunately, silo weighing systems offer a solution to these issues and can help eliminate them altogether.

Weight-based inventory measurement

Simply adding a weight sensor to your vessel is only the first step in implementing a system for dry bulk inventory management. It is the collection and analysis of data provided by the sensor, through a controller, that truly begins to yield valuable insights.

Maximizing the reliability and consistency of inventory measurement through the manufacturing process is key to:

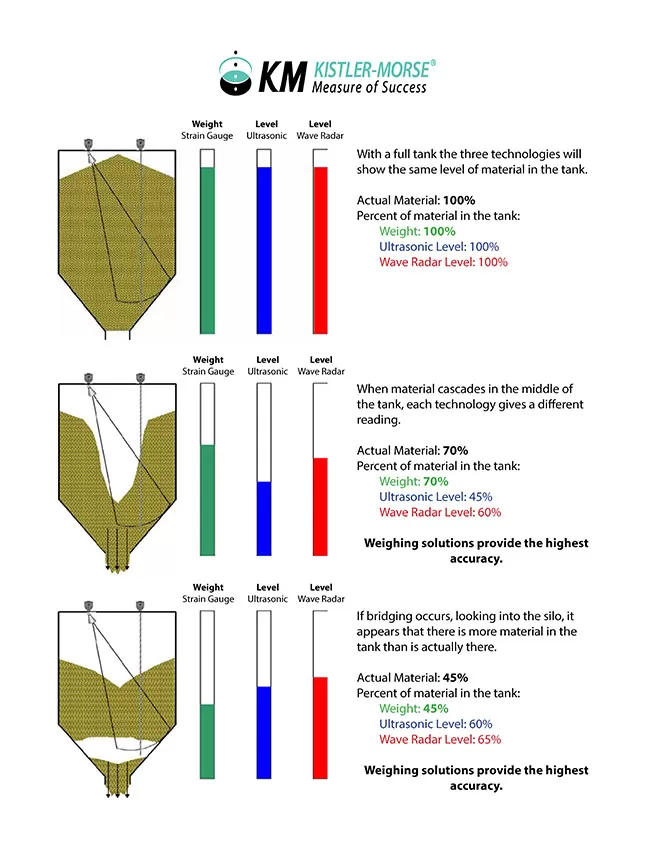

Accurate detection of contents in storage tanks, silos, and process vessels can be a challenging task. Traditional measuring systems such as hydrostatic sensors, potentiometric probes, or radar often have their limitations. In certain application environments, these methods may not be precise, fast, or flexible enough, or may not be practical for technical or economic reasons.

This is especially the case with:.

The solution: turn your container into a precision scale

Bolt-On Weighing Cells:

Microcell® and L-Cell® sensors are highly durable, dependable, and compact, making them a cost-effective solution for measuring inventory in vessels with leg support structures or skirted silos. By using these sensors, the risk of measurement inaccuracies caused by material characteristics such as the angle of repose, rat-holing, bridging, moisture content, and compaction can be avoided with reliable precision. Depending on the vessel type, the sensors are mounted using bolt-on technology on the structural support members and shear beams support or structural skirt.

Applications:

Further benefits:

Weighing modules Load Disc:

The Load Disc weighing systems dynamically measure the contents of process or storage containers and precisely indicate even the slightest changes in weight. They are firmly bolted between the container feet and the foundation. The very low overall height ensures stability and tilt resistance. Transverse forces caused by agitators are compensated. Their compact, sanitary design with polished surfaces and high water resistance (NEMA / IP) class that they can be cleaned in accordance with sanitary requirements in food or pharmaceutical applications. In addition to the Load Disc pressure measuring modules, which are mounted between the vessel and the foundation, a tension measuring module is also available. The Tension Cell is inserted between the suspension and the container body in suspended containers.

Applications:

Further benefits:

Load Stand:

The solid bolting makes Load Stand II a structurally load-bearing integral component and connecting element between the container base and the foundation, and ideal for large containers, tanks and skirted silos. Thanks to the extremely long service life of the strain gauge cells and their easy replaceability, there is practically no limit to the service life of a Load Stand II.

Applications:

Further benefits:

Controllers:

Controllers complete the sensors to make up a complete system. They monitor and provide stable and accurate weight readings from 1 to 120 vessels of level, weight or a combination of the two. The local display provides a user friendly and easy configuration. The output controls can connect to the ORB system or feed into a larger, company wide configuration.

Data management systems:

They store and access real-time inventory information from a remote location via the Internet. Multiple sites with multiple vessels can be monitored and managed. Reports can be run for inventory tracking and trends.

Inventory management systems:

Inventory values are measured by new or existing weight sensor or level sensor attached to your facility’s silos. AccuBin™ offers the flexibility of providing the best sensor solution for your application or configuring to pre-existing sensors. The system then transmits data such as weight, temperature, consumption rate, and sensor status to the Gateway through a device called Smart Node. The Gateway manages all messages between the Smart Nodes and the cloud by Wi-Fi or cellular data. Users gain remote access to this critical inventory data through their browser or AccuBin™ app on the computer or mobile device.

Here you can download the brochure “Complete Weighing System” as a PDF file.

Go to the Kistler-Morse sensors (Bolt-on / Load Discs / Load Stands)

Go to the Kistler-Morse controllers (Single / Multi-vessel)

Go to the inventory Management System ACCUBIN

You found all required info and want to order products: Find your distributor

You need additional info to select the product which fits your needs best: Contact your sales representative

Copyright © 2022 Anderson-Negele