Food, Beverage and Dairy

Life Sciences

Food, Beverage and Dairy Life Sciences

Food, Beverage and Dairy

Life Sciences

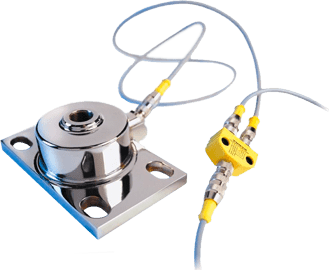

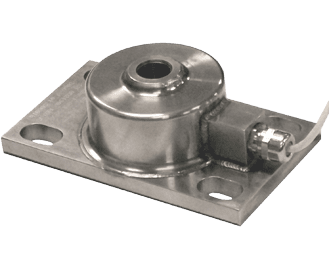

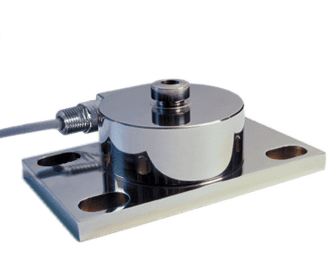

LD360s Load Disc

Weighing Systems, Kistler-Morse Weighing Solutions, Level Sensors

The Hygienic Specialist: Dynamic content measurement through precise weight measurement, robust and polished design for all sanitary applications

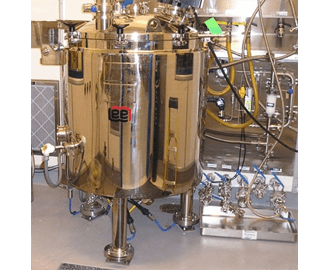

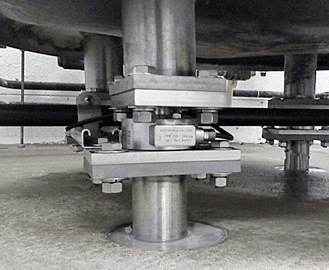

The LD360s Load Disc Compression Weighing Systems dynamically measure the vessel content based on the container weight and precisely indicate even the smallest changes. They are firmly bolted between the container feet and the foundation. They thus enable highly accurate content monitoring in all types of process or storage containers, including, for example, agitators. Due to their compact, hygienic design, they can be cleaned according to sanitary requirements in food or pharmaceutical applications.

- Reliable hygienic measurement: Polished surface and sanitary design with no critical gaps or poorly cleanable openings

- Unique mounting versatility: Various, three-dimensional adaptive mounting systems compensate for unevenness and movements of the vessel

- Flexible: Also for interchangeable vessels, e.g. ingredient containers

- Always precise: Unlike other level sensors, thermal or density changes do not affect the measurement result

- Reliable: Kistler-Morse pioneered load cell technology. This is still the standard for load and content measurement in many industries

Key Benefits:

Product Information:

Technical Specification

| Wetted material | Stainless steel 1.4542 (17-4 PH 900), polished surface |

| Measuring range | 1,000…25,000 lb |

| Accuracy | 0,08 % of rated load (=0,8 lb at rated load 1000 lb) |

| Available versions | Compact | Remote |

| Temperature range process | -0…100 °F |

| Temperature range CIP/SIP | 135 °C / max. 60 min. |

| Communication | 10...30 V DC |

Application

Download

Key Benefits:

Product Information:

User manuals:

Copyright © 2022 Anderson-Negele