Optimize your processes with advanced turbidity sensors and meters, designed for real-time, inline monitoring. Perfect for product differentiation, phase transitions, and quality control, our turbidity solutions ensure high precision across a range of industries, including food and beverage.

Modular flush turbidity sensor for low to high turbidities 200…300,000 NTU, with IO-Link.

Ideal for e.g. phase separation, yeast harvesting, CIP return control.

For very low turbidities 0…5,000 NTU, for pipes from DN25.

Ideal for e.g. efficiency improvement in separator automation, lauter tun and filter monitoring.

For very low turbidities 0…5,000 NTU, for pipes from DN25.

Certified for water management e.g. fresh and waste water control

Turbidity control is a preferred method for differentiating media in inline processes within the food and beverage industries. The ITM series of sanitary insertion turbidity meters from Anderson-Negele provides precise, real-time monitoring and control of these critical processes.

Our in line turbidity sensors offer two advanced measurement methods, ensuring optimal control and resolution for any level of turbidity. Whether you need to monitor high-purity media with a low range of 0 to 5 NTU (0 to 1 EBC) or manage products with medium to high turbidity levels up to 300,000 NTU, we have the right solution.

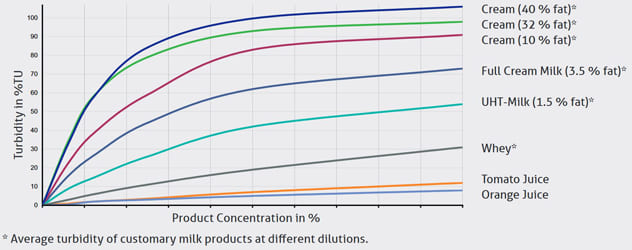

Dairy products like milk or cream, where fat particles behave similarly to other turbidity particles, can also be analyzed with exceptional accuracy. Below, you’ll find examples of turbidity values for various media and how they change with different concentrations:

Inline turbidity analysis enables automated, high-precision control in various production processes and applications. Key uses include product differentiation, phase separation, process control, and quality monitoring.

Product differentiation:

Turbidity sensors help distinguish between different liquids, ensuring correct processing, storage, or filling. Examples include:

Phase transition: Combined with conductivity measurement, inline turbidity sensors enable precise CIP (Cleaning in Place) control. Real-time monitoring of phase transitions (e.g., water to caustic, acid to product) ensures safe, efficient, and resource-saving phase separation, optimizing cleaning quality. For instance:

Process control: Turbidity levels can trigger process corrections through signals to the PLC. Typical applications include:

Quality monitoring: Turbidity sensors ensure consistent product quality by monitoring concentration levels:

Wondering if installing a turbidity sensor is financially worthwhile? Find out in just a few clicks with our ROI calculator.

Inline turbidity analysis offers significant time and resource savings compared to time-based control or visual monitoring, particularly during phase transitions. For example, one of our customers reduced phase transition time by 65 seconds compared to time control methods (open case study).

Use our ROI calculator for a quick estimate of how fast a turbidity sensor installation can pay for itself through product cost savings. Start your calculation now by clicking the links below:

Calculate YOUR possible ROI with US$ and liters.

Calculate YOUR possible ROI with US$ and gallons.

Calculate YOUR possible ROI with CAN$ and litres.

Turbidity sensors provide real-time, automated monitoring of liquids in various production processes and CIP systems across dairies, breweries, the beverage industry, wine production, juice production, and other food companies. Here’s how they can benefit your operations:

| Technical Specifications | ITM-51, ITM-51R Relative Turbidity Meter | ITM-4 Four-beam Turbidity Meter | ITM-4DW Four-beam Turbidity Meter |

|---|---|---|---|

| Process Connection | CLEANadapt | Tri-Clamp | Varivent | Tri-Clamp | DIN flange | Milk tube | Hygienic thread | Tri-Clamp | DIN Flange | Milk tube |

| Wetted Materials | Stainless Steel 1.4404 (316L), Ra ≤ 0.8 μm | Optics Sapphire | Stainless Steel 1.4404 (316L), Ra ≤ 0.8 μm PEEK | Optics Sapphire | Stainless Steel 1.4404 (316L), Ra ≤ 0.8 μm | PPSU (only for drinking and process water) | Optics Sapphire |

| Measuring Range | 200…300,000 NTU | 0.1…200 % TU |50…75,000 EBC | 0…5,000 NTU | 0…1,250 EBC | 0…5,000 NTU | 0…1,250 EBC |

| Accuracy | ±3% of the measurement value | ±2% of the measurement value | ±2% of the measurement value |

| Available Versions | Compact | Remote | Compact | Compact |

| Temperature Range: Process | -10 … 130°C | 0…100°C | 0…100°C |

| Temperature range: CIP/SIP | 140°C / max. 120 min. | 130°C / max. 30 min. | 130°C / max. 30 min. |

| Operating Pressure | -1…20 bar | max. 10 bar | max. 10 bar |

| Communication | IO-Link and 4…20 mA (4-wire loop) | 4…20 mA, PNP | 4…20 mA, PNP |

In practice, detecting the degree of turbidity can be challenging, yet it is crucial for both the quality of the final product and the efficiency of the process. Common methods like manual sampling or turbidity monitoring via sight glass are still frequently used. However, these approaches often result in high labor costs and inconsistencies in sample quality.

Another widely used method, particularly for CIP cleaning, is time-controlled phase transition. To avoid contamination, a safety buffer of several seconds is typically added, which leads to additional costs. This is because valuable product or cleaning agents are often wasted, ending up in the wastewater.

Anderson-Negele’s ITM series turbidity meters can automate this process with exceptional accuracy and resolution. By reducing the risk of resource loss during phase transitions and minimizing labor costs associated with manual monitoring, these turbidity sensors can significantly lower operational expenses. In many cases, the investment in Anderson-Negele turbidity sensors has paid off in a very short time.

Anderson-Negele turbidity meters utilize two primary measuring principles: the backscattered light method for relative turbidity measurement and the four-beam method, which records both transmitted and scattered light. Both methods are designed for inline measurement, allowing for real-time analysis of liquids during the production process. With response times of less than one second, these sensors enable precise monitoring and control, ensuring optimal process efficiency.

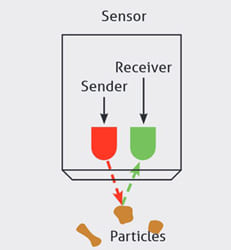

Relative turbidity measurement, using the backscattered light method, offers key advantages such as seamless inline sensor installation and cost-effectiveness. The ITM-51 turbidity sensor is highly adaptable and can be easily retrofitted into existing pipelines as small as DN25.

The sensor operates by emitting infrared light from an LED at its tip through a durable sapphire optical system. Suspended particles in the medium reflect this light back to a receiving diode at the sensor tip, a process known as the backscattered light method. The sensor’s electronics then calculate the relative turbidity based on the reflected signal. This method is particularly well-suited for measuring media with medium to high turbidity levels (200 to 300,000 NTU).

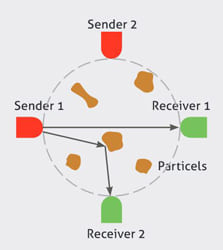

The ITM-4, turbidity sensor utilizes the four-beam alternating light method, a highly sensitive technique that combines transmitted and scattered light measurement. This method is powered by an LED light source and is designed to detect even the slightest changes in turbidity, with measuring ranges starting as low as 0 to 5 NTU (0 to 1 EBC).

The sensor is equipped with two infrared transmitters and two infrared receivers, arranged in a circular configuration, each offset by 90°. The transmitters operate alternately: when transmitter 1 is active, receiver 1 detects the transmitted light while receiver 2 captures the 90° scattered light. The process reverses when transmitter 2 is active. An exact turbidity value is calculated from the four measurements obtained in a single cycle.

One of the key advantages of this method is its ability to automatically compensate for disturbances, such as optic contamination or component aging, by providing a transmitted light reference for each scattered light measurement. Additionally, sporadic interference from solids or air bubbles is minimized through the evaluation of multiple measurement cycles and the application of an adjustable filter.

The ITM-4 is designed for easy integration, fitting into pipelines ranging from DN25 to DN100 (or 1″ to 4″) using a sanitary screw fitting or clamp connection.

This method is also employed in the ITM-4DW variant, which is specifically adapted and approved for drinking water applications. The ITM-4DW offers a cost-effective solution while maintaining the high accuracy and reliability of the ITM-4.

The ITM series turbidity sensors are engineered to meet international standards for food processing equipment, including 3-A, EHEDG, and FDA guidelines. These standards ensure that the sensors are free from dead-legs and are easy to clean, making them ideal for hygienic applications.

The sensors are constructed with the highest quality materials, from the wetted parts to the housing:

Designed for extreme durability, the sensors feature a long-life design and use an LED light source, allowing them to withstand harsh mechanical stresses such as vibrations and pressure surges common in real-world applications. This robust construction ensures top-tier accuracy, longevity, and cleanability.

Anderson-Negele turbidity sensors offer a wide range of process adaptations, providing flexibility for both new installations and retrofitting existing systems.

Copyright © 2022 Anderson-Negele