Sensors with IO-Link in Flex-Hybrid Technology (digital IO-Link and analog 4…20 mA in parallel) make planning, commissioning and operation of your plants easier, faster and more flexible. We offer a wide range of sensors with IO-Link communication ...

The benchmark for precision in level and pressure control, even with turndown and temperature changes. FOOD and LIFE SCIENCE versions available.

Temperature compensated transmitter for process pressure and level measurement in pipes and vessels | With IO-Link

Modular flush turbidity sensor for low to high turbidities 200…300,000 NTU, with IO-Link.

Ideal for e.g. phase separation, yeast harvesting, CIP return control.

Compact electromagnetic flow sensor for media with minimum conductivity >5 μS/cm | With IO-Link

Compact, modular, individually configurable temperature sensor for food applications, processes, tanks and tubes │ With IO-Link

Compact, individually configurable Mini temperature sensors and RTDs for food applications, processes, tanks and tubes │ With IO-Link

The NSL-F is the next generation of potentiometric technology. It is a direct replacement for the LN and offers additional features.

Integral (all in one) Inductive sensor-transmitter used for in-line measurement of process liquid conductivity. Now available with IO-Link capability.

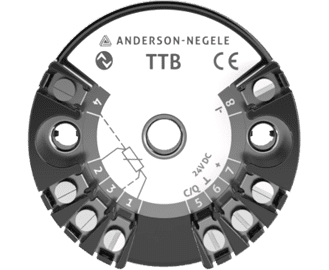

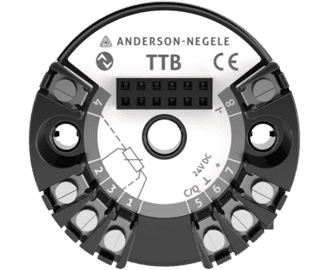

Programmable transmitter in Flex-Hybrid technology with IO-Link and analog output

TTB-D Temperature Transmitter with integrated illuminated LCD display, for temperature sensor head 50 or 55 mm, analog 4…20 mA

Sensors with IO-Link in Flex-Hybrid technology make planning, commissioning and operating your plants easier, faster and more flexible. For existing analog plants, Flex-Hybrid means easier programming, sensor changes with “plug-and-play”, and if you upgrade to IO-Link interface at some point, the sensors are changed over just by plugging them in.

IO-Link is a universal communication protocol that‘s digital and not limited to a specific fieldbus. It adheres to the IEC 61131-9 standard, and many manufacturers of pumps, sensors, valves, and other components offer IO-Link compatible devices. This allows for easy connection of entire process plants or skids to the PLC by simply plugging in the devices. Its bidirectional data transmission system ensures an interference-free connection and provides real-time status updates to avoid production disruptions. It‘s easy to install and commission thanks to plug-and-play technology, and replacing sensors is a breeze with the “Smart Replace Design“ that automatically detects, configures, and parameterizes the new sensor.

FLEX-HYBRID is a technology by Anderson-Negele that allows for digital IO-Link, analog 4…20 mA, and even parallel communication in one sensor.

Our tip: Opt for a Flex-Hybrid sensor when purchasing or replacing sensors. It lets you leverage the benefits of the digital age already today, such as simplified programming or plug-and-play sensor replacement. And if you upgrade to IO-Link control at some point, the sensors switch over just by plugging them in.

Short and sweet: Absolutely! The IO-Link consortium is widespread and active worldwide, making an IO-Link version available for almost every sensor and actuator type. Anderson-Negele alone provides sensors for various measuring ranges such as flow, level, pressure, turbidity, conductivity, and temperature from a single source. Additionally, our flow monitors and point level detectors with their on/off output can be processed directly as digital signals by the IO-Link master.

And those sensor types which are not yet available as IO-Link devices can be integrated with a mA-IO-Link converter that screws onto the M12 connection and converts an analog 4…20 mA signal into a digital signal.

Our Tip: Compile the list of sensors and actuators you plan to use in your plant. You will see: For most processes in the food and beverage industry, you can already today operate everything with IO-Link!

The main benefit is up to 50 % savings on cabling, both for the installation time and cost as well as for the material itself. Typically, each cable must be laid in parallel wiring continuously from the sensor to the PLC or control unit. Usually this has to be a shielded special cable. This means enormous costs for the often very expensive special cables, which also have to be laid over a long distance. In addition, this leads to a high installation effort for the cable ducts and brackets, as well as for connection of the entire cables by specialized plant electricians.

IO-Link simplifies all this by connecting each device to a local IO-Link master with just one cable. From the master, only one cable is needed to connect to the PLC. As digital data transmission is resistant to interference, standard M12 cables are sufficient for this purpose.

Our Tip: Our customers have reported both a 50 % reduction in labor costs and material costs for cable installation with new plant setups. Imagine cutting your cabling expenses in half – that‘s exactly what users have experienced. Calculate your own costs for cables and labor and see how much you could save with IO-Link.

IO-Link devices are configured by connecting a computer to the IO-Link master. You just have to download sensor specific data, the IODD (IO Device Description) from a central database. Then you can enter the configuration of all the parameters, such as the measuring range for turbidity or the temperature display in either °C or °F, for the process. This programming is saved in the IO-Link master and can be copied directly to other sensors using copy-paste if multiple sensors need to be configured in the same way. This allows for faster set-up and fewer sources of error. You only have to use one interface to configure all devices and sensors, eliminating the need for product-specific programming adapters, special hardware and software, or programming directly on the sensor display.

Our Tip: Thanks to Flex-Hybrid technology, for existing analog systems you can also take advantage of these special benefits:

Thanks to the standardized communication protocol used across all sensors, actuators, and control components, setup and commissioning with IO-Link is simple and fast, even for those without expertise in the field. With just a few hardware and software components, you can get started with IO-Link:

Our Tip: To configure all sensors, simply connect the IO-Link master to your computer via USB cable or wireless function. With just one software, you can configure, save, and transfer all configurations to other sensors, retrieve status reports of sensors, and even change settings remotely via protected access while the process is running. This provides you with complete control over your processes and all devices involved at all times.

Not all devices are already available with IO-Link. You can still integrate such components into the IO-Link system. By means of converters, you can use other signals from the sensors. Additional functions such as the status reports on the sensors themselves are not possible in this case, but the correct operation of the system is not a problem.

Our Tip: I/0 devices with PNP signal for On/Off can be connected directly to the IO-Link master. These are e.g. our flow monitors and point level sensors. For all 4…20 mA devices, special converters can be used to transform the analog current signals into digital data.

Many of our customers rely on Anderson-Negele sensors to meet diverse, everyday challenges. Discover how leading beverage producers have successfully overcome obstacles with our sensor technology. Our case studies highlight real-world examples of how we’ve helped clients achieve their goals through expert application consulting, product testing, and technical support.

View Case studies and Application Reports

Our Tip: The Bellarine Foods dairy was fully implemented using IO-Link. This case study provides a detailed look at the many benefits of digital communication. If you‘re also seeking solutions for process optimization, quality improvement, or cost reduction in your company, we‘d be happy to visit your site and help you find answers to your questions.

Contact us Today to Schedule a Site Visit!

Our “Instrumentation with IO-Link / Flex-Hybrid” brochure provides an in-depth look at Anderson-Negele’s IO-Link sensors. It includes general information, product overviews, and detailed technical specifications for sensors with digital and Flex-Hybrid communication capabilities. Discover all you need to know in one convenient resource.

Copyright © 2022 Anderson-Negele