Dairy

Food & Beverage

Dairy Food & Beverage

ILM-4 Inductive Conductivity Sensor

Conductivity Sensors, CIP Control, IO-Link, Process Analytics

Now with 5 years warranty! More details: click here

ILM-4: The new generation of conductivity sensors. With IO-Link

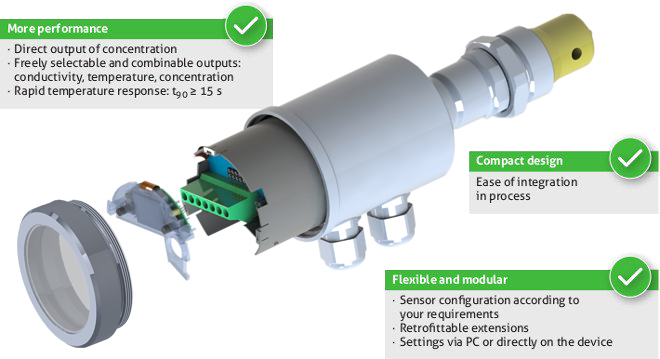

Anderson-Negele’s ILM-4 inductive conductivity sensor-transmitter offers an all in one design that makes integration and commissioning a fast and simple task. Built with flexibility in mind, the ILM-4 can offer multiple outputs freely configurable to multiple conductivity measurements at independent ranges or a combination of conductivity and temperature. With only 1.2 sec the sensor response time is extremely short, enabling real-time control. Unlike other inductive sensors, the ILM-4 has a fast reacting integral PT1000 sensor that can be used to monitor process temperature eliminating the need for a second temperature sensing device. Available in multiple wiring configurations, the ILM-4 configurable with single cable operation for simple conductivity applications or dual cable operation to utilize all available output and input capabilities. Standard with all models is an operational range up to 999 mS/cm and temperature compensation over a range of 0° and 150°C.

Measurement of conductivity of liquid media for

- Controlling of CIP processes (e. g. phase transition detergents / water)

- Concentration measurement (e.g. Alkali and acid concentration in remaking)

- Monitoring of product quality & quality control

The conductivity meter ILM-4 is compatible with the predecessor models ILM-2 and ILM-3.

All details about IO-Link properties, parameters, diagnostics, events and more can be found in the IODDViewer. Just click here.

Add-On Instructions (AOI) are available at www.anderson-negele.com/aoi

Technical Specification

| Process Connection | CLEANadapt G1" / Tri-Clamp / Varivent |

| Insertion length | 20 / 50 mm |

| Wetted material | Stainless steel, 1.4305, SW 36 mm |

| Wetted material 2 | PEEK (FDA conform) |

| Measuring range | 0...1000 mS/cm |

| Accuracy | Slope ±1 % of measurement value | Offset ±20 μS/cm |

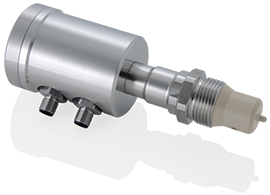

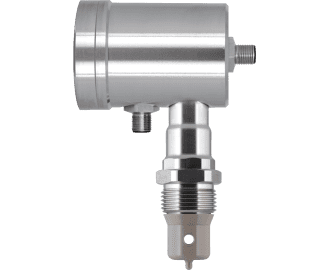

| Available versions | Compact | Remote | Horizontal head | Vertical head |

| Temperature range process | 14...266 °F (-10...+130 °C) |

| Temperature range CIP/SIP | Up to 302 °F (150 °C) max. 60 min |

| Operating pressure | max. 16 bar |

| Communication | 4…20 mA, IO-Link (Flex-Hybrid Technology) |

| Dimensions / weight | ø 63 mm, approx. 750 gr. |

| ILM-4 Benefits | Benefits in production and CIP / SIP processes:

Benefits in cleaning agents control:

Advantages of the ILM-4 conductivity sensor: |

Application

Videos

ILM 4 conductivity meter machined toroid design

PEEK toroid of the ILM-4 conductivity meter doesn’t crack

Demo of the operational screen selection on the ILM-4 conductivity meter

Instructions on how to change the operating range of an ILM-4 conductivity meter

How to change the temperature units on an ILM-4 conductivity meter

How to program the Temperature Compensation parameter of an ILM-4 conductivity meter

How to password protect the programming of an ILM-4 conductivity meter

Copyright © 2022 Anderson-Negele