Reliable efficiency and quality in yeast harvesting, lauter tun monitoring, CIP, and much more

Brewery

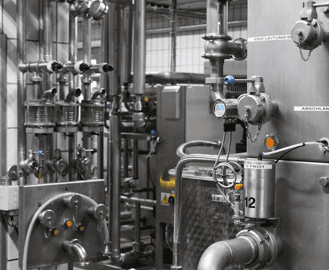

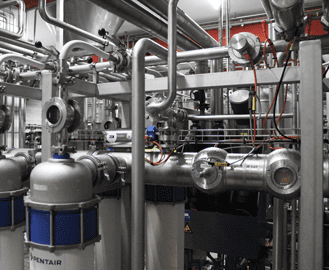

The Leibinger Brewery in Ravensburg, a city in southern Germany can look back on over 125 years of tradition. While honoring its past, the company is also always looking ahead, pioneering the use of new technologies and processes to consistently and reliably ensure the best possible quality of its products. Leibinger was one of the very first breweries to use Siemens Braumatik process control and crossflow membrane filtration to replace diatomite. Today, the entire team continues to embody this mindset, looking for and implementing new ideas to make the brewing process even more consistent, reliable and efficient. This use of high level automation and high-precision sensor technologies ensures that the growing customer base can always and consistently enjoy the best beer.

Brewery Leibinger

Brewery Leibinger

Customer

Johannes Kehrer, Head of maintenance

"At Leibinger, innovations, further developments, and continuous improvements are in the genes. With Anderson-Negele, its sensors, and its support, we have an excellent partner to implement this principle in the best possible way."

— Johannes Kehrer, Head of maintenance

Advantages in the application

- In all process steps, the sensor technology ensures reliable monitoring and active process control, producing a predictably consistent high product quality

- The high degree of automation increases staff efficiency as they can shift their focus to other areas

- Switching in real time when a target value is reached, along with greater precision in the process control help to shorten process runtimes, save resources such as water, cleaning agent, or product, and reduce energy consumption

Application Detail

The Leibinger Brewery in Ravensburg, a city in southern Germany can look back on over 125 years of tradition. While honoring its past, the company is also always looking ahead, pioneering the use of new technologies and processes to consistently and reliably ensure the best possible quality of its products. Leibinger was one of the very first breweries to use Siemens Braumatik process control and crossflow membrane filtration to replace diatomite. Today, the entire team continues to embody this mindset, looking for and implementing new ideas to make the brewing process even more consistent, reliable and efficient. This use of high level automation and high-precision sensor technologies ensures that the growing customer base can always and consistently enjoy the best beer.

The application

Johannes Kehrer, Head of Maintenance, is responsible for the smooth operation of the entire brewing and manufacturing process, which produces 16 different beer varieties. Brauerei Leibinger offers its customers a broad range of drinking pleasures with the highest level of quality. The consumers should be able to rely on what they get, making fluctuations in the quality of their products out of the question for Kehrer. He sees automation as the key approach for many process steps to achieving this goal and constantly tests new techniques or products. Additionally, the brewery benefits from increased efficiency and yield in production. The noticeably improved sustainability through less consumption of resources, water, and energy are welcome side effects.

Turbidity measurement: The all-purpose tool for the brewing process

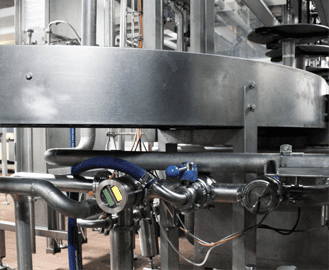

- Leibinger brewers rely on their brewing skills, expertise, and experience to optimize recipes and process sequences and program process control accordingly. The former use of sight glass for the next process step has long since been replaced by a series of turbidity sensors.

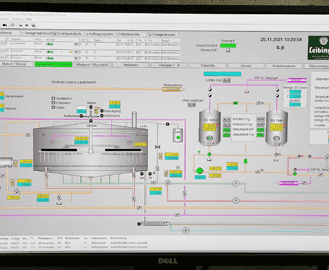

Lauter tun::

-

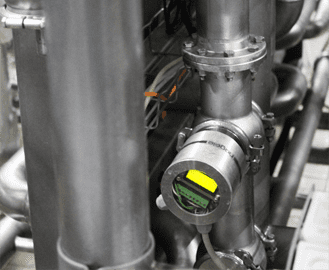

- In the control center directly next to the lauter tun, the high technical level of the company becomes clear. Leibinger was one of the first breweries to introduce the Siemens Braumat process control system, even before its official market launch. Today, a virtual machine works here on a supercomputer to control all processes and run simulations including the controlling of the lauter tun. An

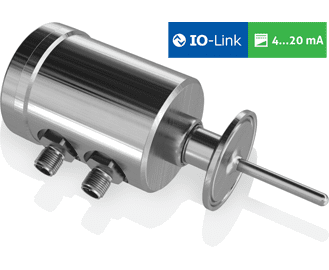

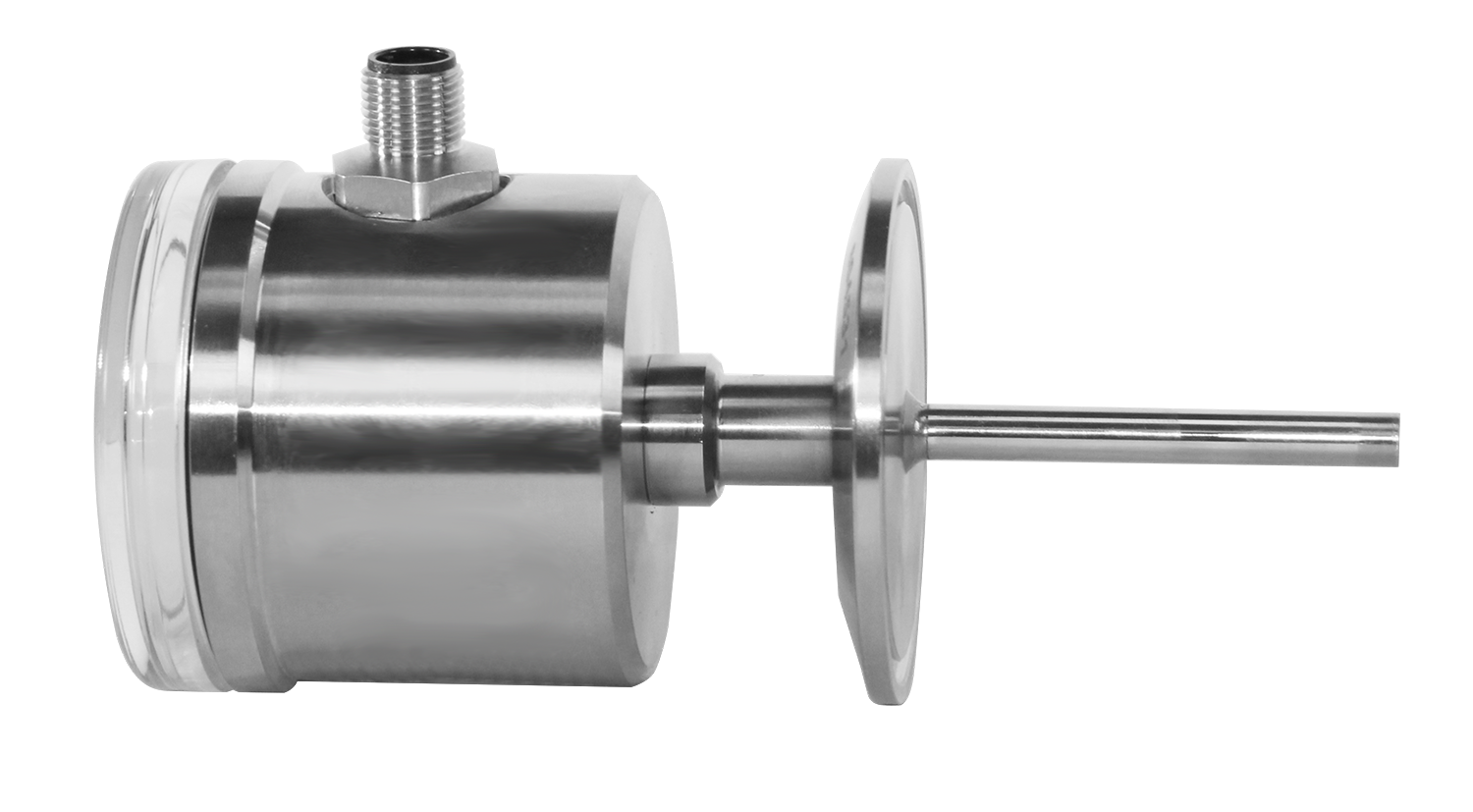

- ensures seamless monitoring of the turbid wort. The process is switched over to the wort kettle as soon as the desired turbidity value is reached. Since the ITM-4 is equipped with an active switching output, the changeover itself can be triggered directly by the sensor. The manual process with a fixed timer value that is otherwise standard in this process step has been replaced by the turbidity sensor, with an effect that Kehrer welcomes:

"Saving 3-4 minutes for each batch, that‘s again something gained."

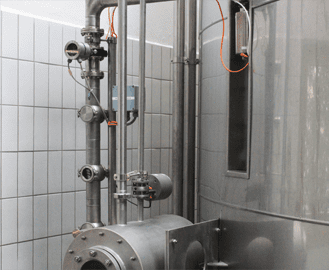

- Yeast harvest::

- Despite running at full capacity, it's surprisingly quiet in the brewhouse and lager cellar. Kehrer explains this, too, with the high level of technology:

-

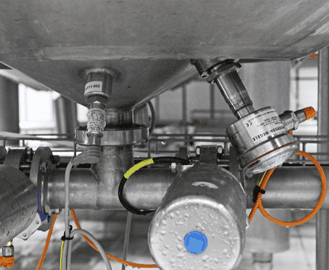

- Here again, turbidity measurement plays a key role in both yeast harvesting in the fermentation tanks and disposal of the spent yeast. The yeast is separated with a

-

- at the fermentation tanks when a preset turbidity value is reached. Then, it can be reused for the next brew, due to the high measuring accuracy in a superior degree of purity.

-

- Following the positive experience in the brewhouse, Kehrer also installed a turbidity sensor for the spent yeast disposal. Here, too, an ITM-51 with its measuring range is perfectly suited.

-

- Previously, an employee had to monitor the right moment to drain the spent yeast for about 15 minutes at the sight glass. And that was three times per storage tank and batch. Kehrer sees the massive savings potential here in the sum of such activities:

"With the intelligent use of sensor technology, we can automate the simple process sequences, and the employees can concentrate on the really relevant and demanding tasks."

- The optimal switching values for each process step and each recipe are determined by the team through tests; here, too, the aim is continuous process optimization.

-

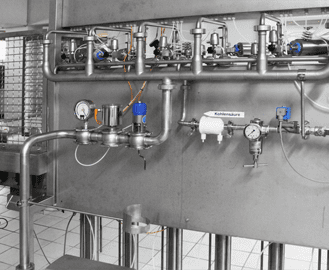

Conductivity measurement: All-round control technology for the brewing process

- Conductivity measurement is a classic measuring method used by Leibinger’s Brewers to control and monitor a large number of process steps as well as the various CIP systems.

Process monitoring:

-

- With a response time of just under one second, the

- can detect a phase switch with high accuracy and precisely control the corresponding valve via an active switching output. In the filling systems for bottles, cans, and kegs, one conductivity meter each ensures that the beer ends up in the bottle and rinse water in the sewer. Highly sensitive conductivity detection and real-time switching ensure reliable product quality and maximum resource efficiency. However, every liter of beer lost is a measurable loss of value and increases the cost of wastewater treatment. And even though water is not a scarce commodity in the region, excessive water consumption represents a cost factor that can be easily avoided with conductivity technology.

CIP control:

-

- Brauerei Leibinger works with decentralized CIP technology: each process area has its own CIP system that perfectly matches the individual requirements. For example, CIP cleaning in the crossflow membrane filter system and the pressure tanks works according to the lost principle, while the CIP return is recovered for recycling in the bottling lines. In all cases, an

- is used to monitor and record the acid/lye concentration for verifiable cleaning efficiency. In the case of multiple-use of cleaners, an ILM-4 is also used to control the concentration of the return flow in the batch tank.

Diverse sensor technology for ever new applications

-

- Thanks to the wide range of products at Anderson-Negele, specifically for breweries, Brauerei Leibinger can focus on one partner for many of its sensor requirements.

"We always find an open ear and partnership-based advice at Anderson-Negele when we want to implement a new project for process optimization. Also, new sensor types or improved product characteristics of the measuring systems always offer new opportunities for improvement."

Plans are already underway to automate the bunging process, which will use P41 pressure sensors to monitor the CO2 content in the pressure tanks. Initial test runs have also been carried out for the production of alcohol-free beer. A particular type of yeast is used here, which, according to Kehrer, offers a significantly better beer taste but is much more demanding in the brewing process. The high measuring accuracy of the sensors is vital here so that temperature, pressure, and all other parameters can be precisely adjusted to the sensitivity of this yeast. For these requirements, too, Johannes Kehrer is sure that he has the right partner.

Copyright © 2022 Anderson-Negele