- Login

- Find Distributor

Food & Beverage

Food & Beverage

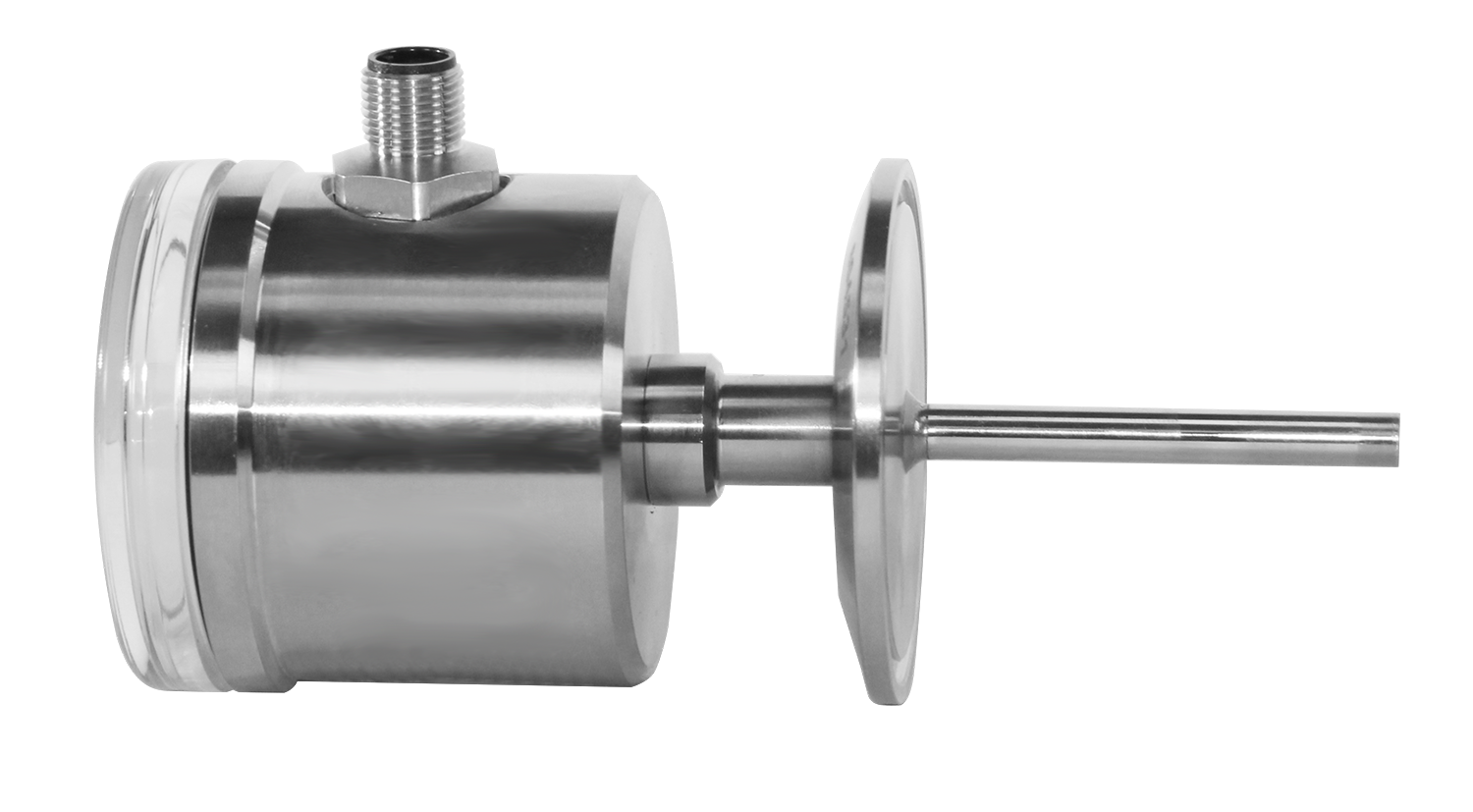

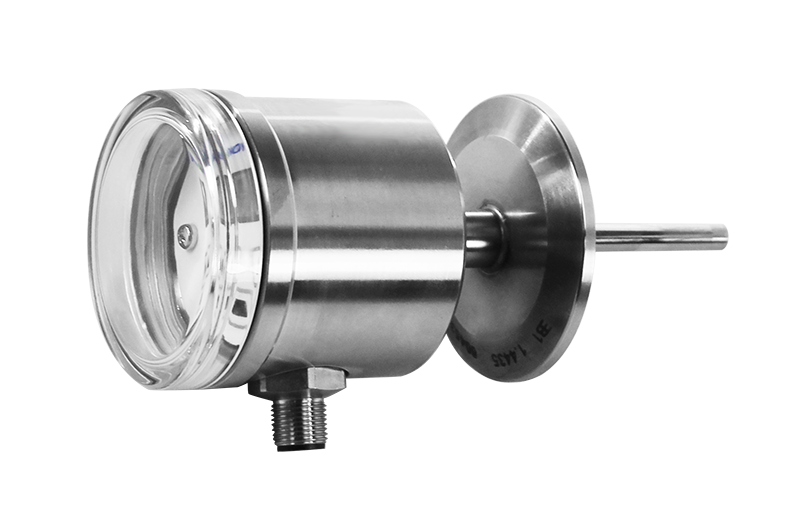

FTS Flow Switch

Flow Meter, CIP Control

Sometimes a flowmeter offers more features and functionality than what is needed. It is often these applications that can be handled by a flow switch which provides a simple digital output indication of when the flow is above or below a user programmed set point. The FTS is Anderson-Negele’s offering for a sanitary 3-A approved flow switch. Unlike competitive products, the FTS-741 offers an all in one design where the clamp connection is one piece with the sensing element. This design eliminates a sealing point between the fitting and the sensor that adds to maintenance and sanitation concerns. It also simplifies ordering as one model number buys a complete sensor instead of having to remember multiple part numbers when ordering. So whether the application is CIP proof of return or controlling a heating circuit for a hot-fill application. The FTS will prove to be the right choice.

Check out various types of sanitary flow meters by Anderson Negele.

Technical Specification

| Process Connection | Tri-Clamp | CLEANadapt Thread connection |

| Wetted material | Stainless steel 1.4404 (316L), Ra≤0.8 μm |

| Measuring range | 0.1…2 m/s |

| Accuracy | ±10% of the end value |

| Temperature range process | 0...100 °C (32...212 °F) |

| Temperature range CIP/SIP | 140 °C (284 °F) (no function) / max. 60 min. |

| Operating pressure | max. 10 bar |

| Communication | PNP |

| FTS Benefits | Reliable flow control for all aqueous, even high-purity mediaFlow switches are used in almost all processes to monitor the technical safety of the plant and the correct operation of the processes. A possible malfunction of a pump, a closed valve or a misdirected medium are reliably detected and reported.

|

Copyright © 2022 Anderson-Negele