Every brewer has the aspiration to offer his customers a consistent, distinctive beer experience. But he also has to ensure an economically successful operation of the business by permanently optimizing processes, resource consumption and costs. It is an expression of the art of brewing to achieve both at the same time for a product that is subject to so many influences and has such a wide variety as beer.

Intelligent measurement technology can help you ensure consistent product quality even with fluctuating raw material qualities throughout the brewing process, automate processes, minimize energy, and resource consumption, and avoid production downtime. Take a look at our product portfolio and compose your ” dream sensor technology”.

As diverse as the raw material quality, the recipes and the procedures in the brewing process are, so are the requirements for the measurement technology. That’s why we offer a complete sensor program, each with a wide range of variants and options, so that you get exactly the performance you want for every application and every plant, from the brewhouse to the fermentation cellar, and from craft breweries to large industrial breweries – no more and no less.

Lautering is often the bottleneck in the brewing process in terms of time; every minute saved in lautering increases overall efficiency. High-precision inline analysis of the wort also helps control the raking and thus accelerate this factor that limits the brewing process.

The plate-and-frame filter is a faster alternative to the lauter tun, with further requirements on process control and measurement technology for a trouble-free filtration process.

Here the goal is to achieve the desired original gravity by evaporating water.

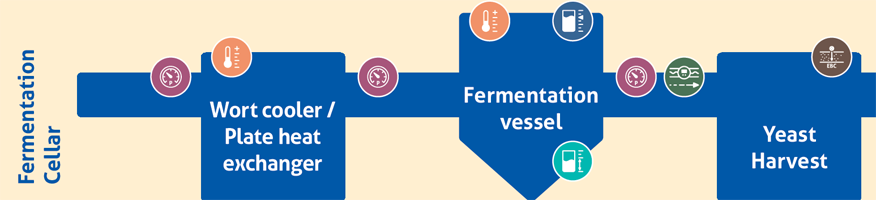

A heat exchanger cools down the hot wort rapidly. Precise temperature control and trouble-free flow of both green beer and cooling medium are important here.

After the yeast has been added, the beer matures in the fermentation tanks. To ensure that the flavor and aroma substances can develop in the desired manner for reproducible beer quality, the fermentation conditions must be maintained with the utmost precision. This includes relevant factors such as wort composition, aeration rate, yeast cell count, yeast strain, yeast management, temperature, and pressure. Today’s fermentation tanks, most of which are closed, must be monitored for overpressure in addition to monitoring the fermentation itself.

Many types of yeast can be reused several times and can be harvested after the fermentation process. A distinct separation of dead yeast and different qualities of reusable yeast is essential in this process.

Depending on the type of beer, turbidity is partially or completely filtered out of the suspension before storage. This can be done by diatomaceous earth filters, crossflow filters, candle filters or centrifuges / separators.

Different filling systems are used for bottles, kegs, and cans. During bottle cleaning, measuring systems monitor the quality of the cleaning and the cleaning agents.

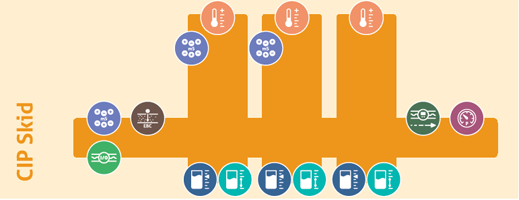

CIP systems for a brewery can be central or decentralized. For improved efficiency, the return flow of the media can be monitored for the degree of contamination by analysis sensors. This allows the expensive cleaners to be automatically returned to the batch tank when the degree of contamination is low, and low-contaminated rinse water can be re-used for pre-rinsing in the next process. With conductivity measurement the cleaner concentration can be monitored and controlled automatically. In our “Solutions” / “CIP Control” section, you will find all the details on how intelligent sensor technology can contribute to resource-efficient and reproducible CIP processes.

Energy consumption is influenced by temperature, process duration and media quantity. A temperature that is slightly too high, or too low in the fermentation cellar, can already mean costs of several hundred dollars per year. If the lautering process runs for 10 minutes too long, energy is also wasted here. A CIP process that lasts longer due to time control, even though the desired degree of cleaning has already been achieved, also consumes resources and energy unnecessarily. Plate heat exchangers and vapor condensers can in turn be used for energy recovery. High-precision sensors with active output for process control and automation can help preventing energy losses and optimizing energy recovery.

Our tip: Examine all processes for their optimization potential. We will be happy to help you on site. Contact us today!

Many of our sensors are available as “remote” version. The actual measuring device and the electronics unit with operating display are separated. This protects the electronics from vibrations and high temperatures and can significantly increase the service life. It is also extremely practical, as you can simply place the electronics and displays where it is most convenient and accessible for easy and quick reading or programming.

Our tip: Get the perfect overview of all processes and vessels without having to bend down or walk around and ensure easy programming and longer service life with remote sensors.

Many processes in the brewery are based on a differentiation according to turbidity, conductivity, or concentration. In practice, deviations in these criteria are often not easy to detect. But they are crucial for the quality of the product, and for the efficiency of the process. Analytical sensors are your “eye in the pipe”, your view inside the process, and can automatically control the process through an active output. This can replace manual sampling or time-controlled phase changeovers.

Our tip: In multiple processes such as lautering, yeast harvesting, whirlpool, bottling, and CIP control, this allows you to save working time, avoid product losses, reduce the amount of wastewater, ensure consistent quality, and ensure that the beer ends up in the bottle and the rinse water in the drain. Find out our Analytical sensor solutions here.

Anderson-Negele products are designed and built exclusively for food applications. Therefore, they meet all requirements for sanitary-sensitive production areas from the very beginning, as evidenced by certifications such as 3-A and EHEDG. This means maximum hygienic protection of your products, easy equipment cleaning, and ultimately maximum peace of mind and enjoyment for your customers.

Our tip: When it comes to process connections, we also offer a wide range of solutions that ensure sanitary integration into your plants through dead space-free design and superior material and surface quality. We have specially developed process connection systems that simplify hygienic installation and operation and can even be retrofitted.

Most Anderson-Negele sensors with IO-Link are equipped with “Flex-Hybrid Technology“, i.e. digital IO-Link and analog 4…20mA communication in parallel. Even if the plant is operated analog, you can commission all sensors with only one software via computer. Specific programming can be easily transferred to other sensors by copy-paste. And in the case of a sensor exchange, the entire individual programming is transferred simply by plugging it in.

Our tip: With Flex-Hybrid Technology, you already have advantages in installation and commissioning. And if you switch to digital IO-Link technology later, there is no need for new sensors. Discover our IO-Link solutions in the menu “Solutions / IO-Link”.

Many customers use our sensors under a wide variety of everyday requirements. Discover how other breweries are successfully overcoming their challenges with Anderson-Negele sensors. Our case studies show examples where we have been able to help our customers achieve their goals through application consulting, product testing or technical support. You can find our case studies online here.

Our tip: Our case studies can give you a small overview of the variety of applications where intelligent sensor technology, used correctly, can make your work easier, improve quality and reduce costs. We would be happy to visit you to find answers to your questions on site. Please contact us!

They are essential in almost every step of the brewing process and for CIP control. That is why we offer our TS sensors in 2 standards (Big and Mini), with a comprehensive performance range and an almost infinite variety of customization, process connections and options.

Keep optimum control of process or vessel pressure at all times. Many sensor options provide the most suitable solution for every application, every requirement and every desired pressure measuring range, be it as an on-site display or for PLC connection.

Different temperatures, different vessel shapes, sometimes pressurized, different densities, differently foaming media, different turbidity and solids contents – highly different requirements and dynamic changes influence the control of the filling level of your various vessels and containers. However, at all times you need to know exactly how much product is in the vessel or ensure that a vessel does not overflow or run dry.

That’s why we offer different measuring techniques and many different designs and options, so that you get the best solution for every purpose and application.

Here is how you maintain control over your brewing recipes and the technical safety of your plant: Precise flow control with electromagnetic flow meters shows you in every process step, from the mash tun to the keg filler, exactly what volume of media is flowing in the processes. Flow monitors give an alarm when the flow stops and are ideal for monitoring pump systems, filters, cooling circuits, the CIP return or for detecting misdirected media. The FWA also offers the output of the flow velocity with approx. 10% accuracy, in many cases sufficient to spare more expensive flow meters.

Do you want to start lautering at the perfect moment, saving time and energy? Ensure maximum reusability during yeast harvesting? Achieve maximum separator effectiveness? Reuse weakly contaminated CIP media and thus save costs? Minimize wastewater costs through pollution monitoring? Maintain precise product quality? Then our turbidity sensors are your perfect solution.

For active, automated phase transition, control of the CIP return of acid / caustic / water and concentration control of the CIP cleaners: ILM-4, your safeguard for process reliability.

For a wide range of sensor types, our connection systems offer a consistent hygienic installation concept: High-quality stainless steel or PEEK for all wetted components, simple and secure screw connection or even installation in thermowells for sensor removal without disrupting the process.

Turn your vessel into a precision scale. When integrated level control systems reach their limits, load cells come into play. In the process as a load disc for installation under the vessel, or for barley silos as a bolt-on load cell on the vessel support construction.

Your key to greater efficiency: sensors with IO-Link in Flex Hybrid technology. These make planning, commissioning, and operating your plants easier, faster and more flexible. For existing analog plants, Flex-Hybrid means easier programming, sensor changes with “plug-and-play”, and if you upgrade to IO-Link control at some point, the sensors are changed over just by plugging them in.

Discover our comprehensive overview brochure that outlines how Anderson-Negele can assist you in optimizing your brewing processes.

Click here to download the brochure “Measurement technology for the brewing process” as a PDF file.

Check out our product portfolio and assemble your “desired sensor technology” for your brewery. Contact us now to get started.

Copyright © 2022 Anderson-Negele