Söbbeke Dairy

Söbbeke Dairy

Customer

Kurt Hölscher, Team leader electrics

"Product quality is the most important criterion for us. But sustainability is also crucial. That‘s why we control so accurately how efficient the technology is. And we are pleased that we could achieve such a significant improvement with the ITM."

Application Detail

The Sobbeke dairy in North Germany has a 100-year tradition and has been making 100% organic products since 1988. Today, approximately 60 million liters of milk are processed each year, coming from over 140 organic farms, all of which are affiliated with the Bioland, Demeter or Naturland organic farming associations. In addition to insisting on the highest quality, sustainability plays a deciding role in the company‘s decisions. To reduce unnecessary product losses at the UHT plant, it was only logical to find the best solution for maximum resource efficiency. And with the ITM-51 turbidity meter, they found it.

The application

After delivery and intermediate storage the raw milk is pasteurized, separated and, if necessary, homogenized. In the UHT plant it is then refined to the end product, such as pudding, rice pudding, or cream. Each phase is individually expelled through water.

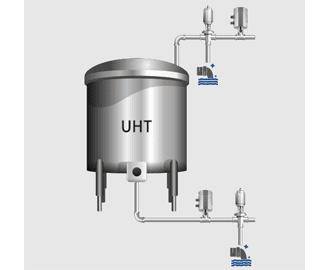

At the feed of the UHT plant, a valve ensures that the rinsing water is discharged completely into the drain in time and does not enter the unit. At the UHT outlet, the product phase is again separated from the water via a valve. Here it is important that no rinsing water gets into the product tank after the UHT plant.

The sensor technology used in the past for the phase transitions at the inlet and outlet proved to be not reliable enough. Therefore, the plant managers changed to pure timer based control. However, in order to avoid any hygiene problem or contamination in the end product, a long time buffer was programmed. The outlet phase, for example, was switched to the sewer early before the rinsing water arrived. This resulted in product losses, which were detected during a process audit. To achieve the highest possible product quality and resource efficiency, a new solution was needed.

The Anderson-Negele solution

The ITM-51 relative turbidity sensor is integrated flush in the process line and measures the turbidity of the product via a sapphire lens. Due to the response time of less than 1 second and the high measuring accuracy, the transition from product to water or from one product to another one can be measured with superior accuracy. This reliable phase transition control within one second helps avoid substantial product losses.

The operator took detailed measurements before and after the ITM-51 installation. He detected that, compared to timer based control, 59 liters of product per phase switchover in both the inlet and outlet are saved: they flow into the UHT system or the product tank instead of being lost in the sewer. In addition, the respective milk products and their quality level in the line can also be precisely monitored by the high precision turbidity measurement.

For the feed, ITM-51 is used as a „remote sensor“. The measuring point at the pipe lowering ensures optimum product contact. For on-site control with easy access, the measuring unit with display is mounted separately. At the outlet, the compact version of the ITM-51 is a perfect design.

Measurement of actual resource savings

Comparative measurement carried out by Söbbeke dairy:

- Discharge time to sewer reduced from 140 s to 75 s, based on ITM-51 measurement values.

- = Time saving 65 seconds

- 1 s at 3300 l/h = 0.91 l/s of product

- 65 s * 0.91 l/s = 59 l

- Result: 59 l * 2 (feed and outlet) = 118 l

Advantages in this application

- Compared to the previous timer based control, 118 fewer liters of product are lost with each phase transition since the ITM-51 turbidity meters have been installed (proven by measurement).

- Only 2 sensors are needed, one ITM-51 for UHT feed control, and one ITM-51 for outlet control.

- Remote version simplifies on-site control at the inlet in a location which is not easily accessible.

Advantages of the ITM-51 Turbidity Meter

- Flex-Hybrid technology with digital and analog interface (IO-Link + 4...20 mA)

- Extremely short response time of 0.75 s

- Extended temperature and pressure range (process temperature up to 130 °C / 266 °F, pressure -1...20 bar)

- No influence due to reflections caused by small nominal diameters or electropolished surfaces

- High reproducibility: ≤ 1 % of final value

- Selectable measuring value (%TU, NTU, EBC)

- Measuring range: 200...300,000 NTU equivalent

Copyright © 2022 Anderson-Negele