Accurate flow measurement is crucial for maintaining safety, efficiency, and precision in industries such as food, beverage, dairy, and life sciences. Our range of hygienic flow meters—including electromagnetic, turbine, and Coriolis mass/density technologies—are designed to meet the stringent requirements of sanitary applications.

Compact electromagnetic flow sensor for media with minimum conductivity >5 μS/cm | With IO-Link

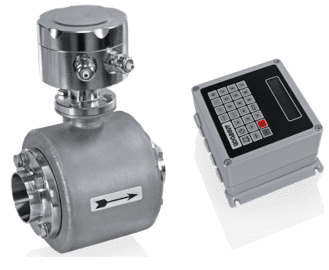

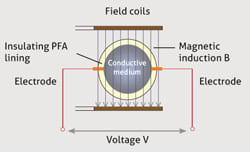

Electromagnetic Flow Meter with integral electronics for conductive liquids or slurries

Compact Coriolis Mass Flow and Density meter for for hygienic applications, even for challenging processes and liquids

The IZMS series electromagnetic flow meter is PMO M-b approved and an ideal solution for measuring conductive fluids and slurries, including those used in the dairy industry.

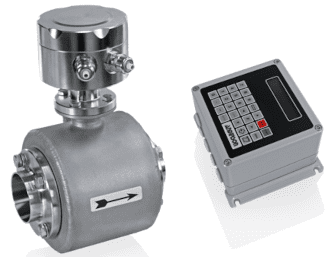

The IZM-Q flowmeter (NTEP-Certified) is a perfect component for integration into US Milk Receiving Systems. It can be paired with the Air Eliminator (AE) for unparalleled accuracy.

Certifiable intake and load out systems for the accurate measurement of milk.

Self contained pressure vessel for the removal of air in liquid products

Turbine flow meter designed to meet BPE requirements for the measurment of liquid flow.

Electronic display with integral PLC to control a batch process application

With over 90 years of expertise in hygienic sensor technology and more than 40 years in magnetic flow meter innovation, Anderson-Negele offers industry-leading solutions for precise flow measurement. Following our integration of GEA Diessel’s magnetic flow meter business, we have expanded our range of advanced flow sensors to meet the evolving needs of the food and beverage industry.

Whether using a magnetic flow meter, Coriolis flow meter, or flow switch, Anderson-Negele provides accurate and reliable flow sensors to optimize production, maintain product quality, and save operational costs.

Our flow meters offer precise monitoring and control of media flow, ensuring safety and efficiency across various applications:

Flow switches are critical for ensuring operational safety and process efficiency in nearly every production plant. They help monitor and signal any potential issues, such as pump malfunctions, closed valves, or misdirected media, ensuring quick responses to prevent costly downtime.

At Anderson-Negele, our flow switches are designed to meet the unique needs of every application, process, and fluid type, offering cutting-edge technology for optimal performance:

Choose Anderson-Negele flow switches to ensure process safety and optimize operations across diverse production environments.

Precise flow measurement significantly reduces costs by preventing resource loss and optimizing usage. High-accuracy flow meters ensure precise quantity and volume measurement, minimizing waste and improving process control. This accuracy enables recipe optimization and better blending control, ensuring consistent quality and efficiency in production. By adhering to exact quantities of valuable resources, you reduce waste and improve overall product quality.

Flow switches play a critical role in cost prevention by detecting system malfunctions that can lead to operational downtime. When flow stops, pumps can run dry, or Clean-in-Place (CIP) processes may fail to meet standards. These issues can result in costly downtime or product loss. Anderson-Negele flow switches provide early malfunction detection, allowing quick corrective action to protect equipment and maintain continuous operation.

Anderson-Negele offers four primary flow measurement technologies for liquid applications:

Scroll down for detailed descriptions of each technology and their benefits.

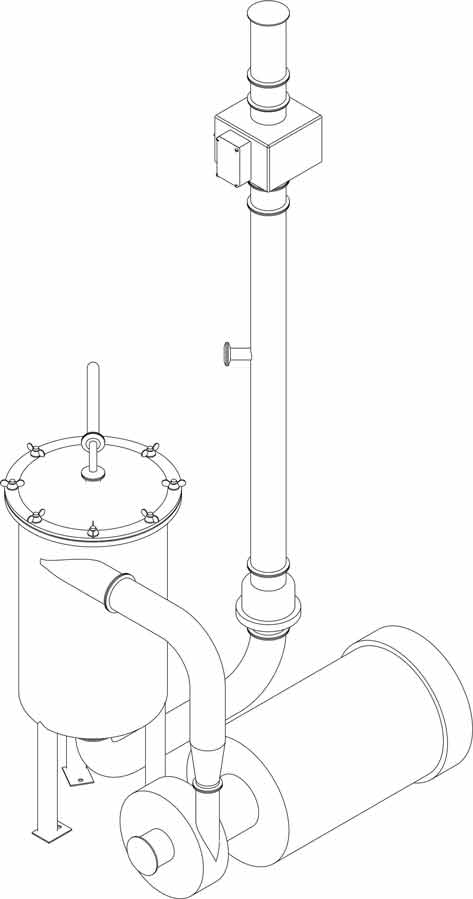

Electromagnetic flow measurement is based on Faraday’s law of induction. A magnetic field is generated within the meter, and as conductive liquid flows through, it induces a voltage proportional to the fluid’s velocity. This measurement method is highly accurate and provides output in the form of a counting pulse, 4-20mA signal, or digitally via IO-Link.

Electromagnetic flow meters are ideal for liquids with a conductivity greater than 5 μS/cm, such as milk, cream, beer, ketchup, sauces, molasses, yogurt, and cleaning agents.

Turbine flow meters use non-contact pulse measurement. The turbine rotor, positioned within the liquid flow, rotates as the liquid passes through. A signal probe generates an electromagnetic field, and the rotating rotor interacts with the field to produce an induction current, which is measured and outputted with precision.

Turbine flow meters are an economical and precise alternative for non-conductive, aqueous media like fruit juice, beer, alcohol, oils, and process water. They are also ideal for demineralized water and cleaning media.

In a Coriolis flow meter the fluid is split into to tubes. An active device forces these measuring tubes to oscillate. At zero flow, the two tubes vibrate in phase with each other, the sinus waves are parallel. When flow is introduced, the Coriolis forces cause the tubes to twist resulting in a phase shift of the sinus waves. The time difference between the waves is measured and is directly proportional to the mass flow rate.

Mass and volume flow measurement: These values are calculated from mass flow rate and the density measurement.

Density measurement: The measuring tubes are vibrated at their natural frequency. A change in the mass of the fluid contained inside the tubes causes a corresponding change to the tube natural frequency. The frequency change of the tube is used to calculate density.

Coriolis meters are perfect for food and beverage processes where both flow rate and density (such as Brix, Plato, Proof, or Baumé value) must be measured. They are especially useful in applications requiring simultaneous flow and density control.

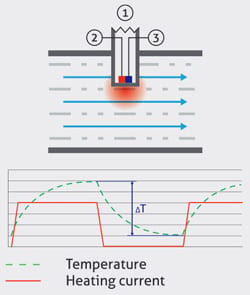

Calorimetric flow switches use a temperature sensor heated periodically to detect flow. As liquid flows over the sensor, it draws heat away, and the temperature difference indicates flow velocity. Anderson-Negele’s design reduces response time and improves measurement accuracy.

This measuring principle is ideal for all aqueous products, including demineralized and highly filtered media such as cola and other soft drinks, filtered beer, demineralized water, as well as for media in pressure lines.

Anderson-Negele’s Flex-Hybrid technology combines the advantages of both digital IO-Link and analog 4-20mA transmission. This dual capability simplifies the transition from analog to digital systems. The FMQ flow meter can be easily switched between digital and analog modes with a simple cable change, providing flexibility in system upgrades. The system also uses a standard 3-pole cable, saving time and installation costs.

Copyright © 2022 Anderson-Negele