IO-Link flagship project with resounding success: Bellarine Foods, a milk powder plant of the future

Dairy

Bellarine Foods in Victoria, Australia, has broken new ground with a completely new plant for whey powder production. The entire project was planned, designed, and installed with the IO-Link Digital Communication System. From the construction phase to production operation, Bellarine Foods has been a pioneer for a technology that represents the future standard for food and beverage companies. The benefits of this project are numerous and one thing is clear to project partner Lindon Giuffrida of GP Systems: „The future of hygienic process technology is digital.“

Application Brochure:

Bellarine Foods

Bellarine Foods

Customer

Lindon Giuffrida, Project Partner

"We only need one interface to program all devices and sensors. All the usual product-specific programming adapters, special hardware and software, or programming on the sensor‘s display are eliminated. This is the best thing ever." — Lindon Giuffrida, Project Partner

Advantages in the application

- Savings in cabling costs of around 50 %

- Savings in planning, set-up, and commissioning time of around 50 %

- Significantly easier programming of sensors, valves, and other devices

- Ability to check sensor status and change settings via the Internet

- Replacement of sensors made easy by plug-and-play with automatic transfer of programming

Application Detail

Bellarine Foods in Victoria, Australia, has broken new ground with a completely new plant for whey powder production. The entire project was planned, designed, and installed with the IO-Link Digital Communication System. From the construction phase to production operation, Bellarine Foods has been a pioneer for a technology that represents the future standard for food and beverage companies. The benefits of this project are numerous and one thing is clear to project partner Lindon Giuffrida of GP Systems: „The future of hygienic process technology is digital.“

The application

Since the end of 2021, the new plant refines approximately 60,000 liters of whey per day, derived from the production of a goat cheese factory, into whey powder. In partnership, HPS Tech & GP Systems supplied the necessary skids, each designed as individual prefabricated modules, which only had to be connected at the plant. Following skids were installed:

- Ultrafiltration membrane system

- Nanofiltration membrane system

- CIP-System

- Tank bay storage system

- Evaporator

- Spray Dryer

Can a complete production plant be operated exclusively with IO-Link communication?

Clear answer: Yes!

After the initial experience of installing IO-Link devices on other plants, GP Systems saw the enormous potential savings IO-Link presented for Bellarine Foods‘ new whey powder plant project.

"We designed each skid so that every sensor, valve, and other device could be connected directly to an IO-Link master," explains Giuffrida.

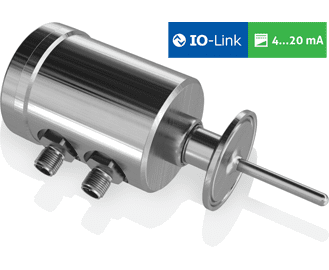

Thanks to the wide range of products range with IO-Link, Anderson-Negele was able to supply sensors for the measuring ranges turbidity, conductivity, flow, level, temperature und pressure from a single source. Flow switches could also be included as their on/off output can be processed directly as a digital signal by the IO-Link master. For specific products which are not yet available on the market as IO-Link devices, such as certain pumps, he also found a solution: a special converter that transforms a 4...20 mA signal into a digital signal. However, this meant additional cost for the converter and no possibility of data transfer from the IO-Link master to the device.

What advantages does IO-Link offer for the design, construction, and connection of the skids?

The biggest advantage is economy in cabling.

Usually, sensors or other devices have to be connected to the PLC or other control device with one shielded cable for data transmission and one additional power supply cable. This means high material costs for the often very expensive special cables, which also have to be routed over long distances, and

high installation costs for cable ducts, brackets, routing, and connection.

Giuffrida can accurately quantify the savings from IO-Link on the Bellarine skids: "We could reduce the pure material costs for the cables and likewise the time and costs for their installation by 50 %."

What advantages does IO-Link offer for the commissioning of the sensors?

This is where Giuffrida expresses all his enthusiasm for IO-Link: "We only need one interface to program all devices and sensors. All the usual product-specific programming adapters, special hardware and software, or programming on the sensor‘s display are eliminated. This is the best thing ever."

In the case of IO-Link devices, configuration is performed by a computer via the IO-Link master . To do this, the sensor specific IODD (IO Device Description) is simply downloaded from a central database. Then the configuration of all parameters, e.g., the measuring range of the turbidity or the

temperature display in °C or °F, is entered for the process. This programming is stored in the IO-Link master. If several sensors need to be configured in the same way, this saved programming can be duplicated directly to all other sensors using simple copy-paste. This allows the individual devices to be set

up much faster and with fewer errors.

What advantages does IO-Link offer in operation?

Each individual device has its IP address so that each sensor can be identified and accessed separately. Access is possible from an external location via protected and secured Internet. "I can configure each sensor from my desk, test it, run simulations, and retrieve or correct the sensor

status if there are problems, even without being on-site."

Giuffrida sees this as a key advantage over analog data transmission, which only allows monitoring and passive „reading“ of data. "With IO-Link, I can actively intervene in every single process and optimize it during operation."

In the same way, the sensor status can be retrieved. This can be used to determine the cause in the event of an error message or even to check the „health status“ of the sensor. It can even be used to determine if the risk of sensor failure is imminent and prepare a replacement device accordingly. According to Giuffrida, however, this has not yet occurred at Bellarine; all sensors have been running smoothly since commissioning, and there has not yet been a single

malfunction with any of the installed devices.

What advantages does IO-Link offer for existing plants with analog operation?

Giuffrida is clear in this respect: "Even in existing plants, everyone should go for a new sensor with Flex-Hybrid technology when replacement is required. Even if the device is operated in analog communication, IO-Link offers so many advantages that it pays off even for existing plants."

Thanks to their Flex-Hybrid technology, almost all IO-Link sensors from Anderson-Negele offer digital IO-Link and analog 4...20 mA communication in parallel. According to Giuffrida, this makes things easier for the user in several ways:

-

- Easy programming and configuration: all parameters can be easily set for the sensor on the laptop, with the same interface. This can also be prepared by a person outside production or even the plant supplier.

-

- Copy-paste for multiple sensors with the same programming: The settings only have to be made once and can then be saved in the IO-Link master or on a computer. This allows additional sensors to be configured simply by copying them with a few mouse clicks.

-

- Automatic programming when replacing sensors: If a programming is stored in an IO-Link master, it can be transferred to the sensor simply by plugging in the M12 cable.

- Digital programming with values from 0...100% is easier than setting with analog data that must be converted for output.

-

- Automatic programming means sensor replacement can be done by anyone. There is no need for specialist knowledge of process technology or maintenance and, therefore, no need to call in specialist personnel. This is particularly helpful in shift operations.

- Spare parts management is simplified because a reserve device does not have to be kept on hand for each configuration. One device per sensor type is sufficient and can be individually programmed quickly and easily via IO-Link master, thus enabling significant savings in spare parts storage costs.

What‘s next for IO-Link?

GP Systems already has several new projects underway that they are designing and implementing with IO-Link, just like Bellarine. For Giuffrida, IO-Link is the future, and he feels affirmed that GP Systems has been so early and consistent in planning and implementing plants with IO-Link. And he is pleased that in Anderson-Negele, he has a partner who is not only also a pioneer in digital communication, but with their Flex-Hybrid technology can offer a forward-looking

solution for both new and existing plants for almost all measurement types.

Copyright © 2022 Anderson-Negele