Product News

Make your processes clear – and save costs!

17 Mar 2025

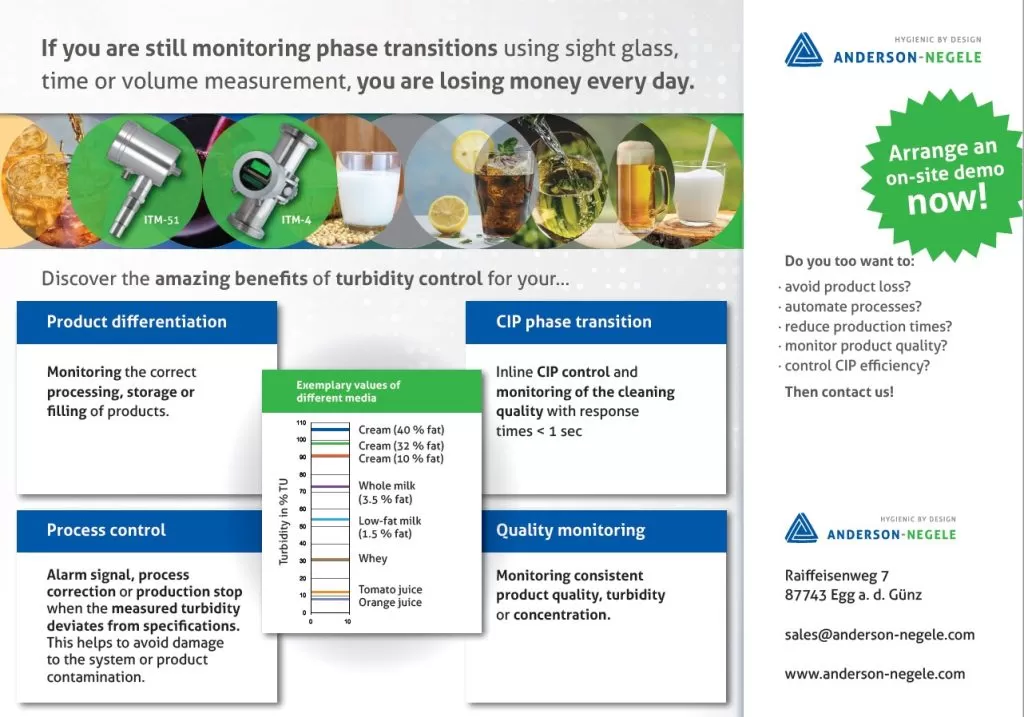

If you are still monitoring phase transitions in a dairy, brewery or beverage production using sight glass, time or volume measurement, you are losing money every day.

In many applications in the food and beverage industry, turbidity measurement is the most suitable in-line analysis technique for differentiating fluids in the process.

Since fat particles behave the same as solid particles or other turbidity-causing substances during turbidity measurement, dairy products can also be differentiated with the utmost accuracy.

With turbidity control you can optimize your production processes to

- Avoid product loss

- Automate processes

- Reduce production times

- Monitor product quality

- Control CIP efficiency

In a new Whitepaper Turbidity control in food and beverage production – Overview, applications and selection criteria, we discuss the advantages and possibilities of turbidity control for the following applications:

- Product differentiation

- CIP phase transition

- Process control

- Quality monitoring

and provide a variety of examples of how these have been successfully implemented by our customers.

Copyright © 2022 Anderson-Negele