A point level switch detects that a defined filling level (max. or min.) has been reached and emits a switch signal for process control. Find here tailored solutions for beverage and food processes and the pharmaceutical ...

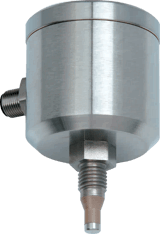

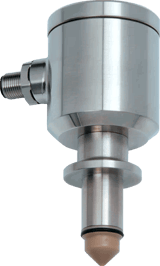

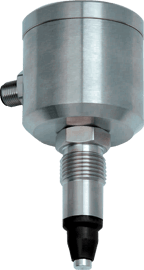

NCS-01 / NCS-02 – Capacitive point level detection in metallic vessels and pipes with hygienic thread M12 (CLEANadapt)

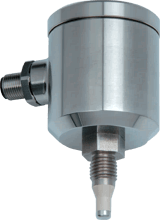

Capacitive point level detection in metallic vessels and pipes with hygienic thread G1/2″ (CLEANadapt)

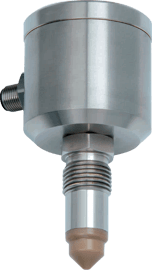

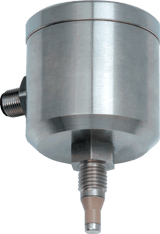

Capacitive point level detection in metallic vessels and pipes with installation length 60 mm and hygienic thread G1/2″ (CLEANadapt)

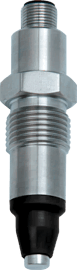

Capacitive point level detection in metallic vessels and pipes with extended sensor tip and hygienic thread G1/2″ (CLEANadapt)

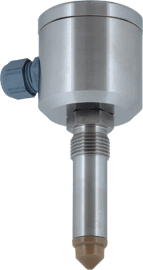

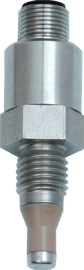

Capacitive point level detection in metallic vessels and pipes, mini-version with hygienic thread G1/2″ (CLEANadapt)

NCS-01P / NCS-02P – Capacitive point level detection in metallic vessels and pipes with hygienic thread M12 (CLEANadapt)

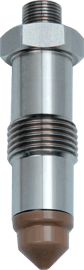

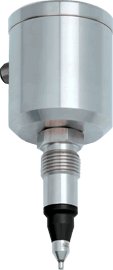

Capacitive point level detection in metallic vessels and pipes with extended sensor tip

Capacitive point level detection in metallic vessels and pipes with direct connection

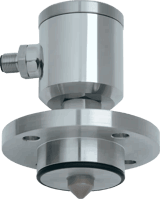

Capacitive point level detection in metallic vessels and pipes with build-in system PHARMadapt EPA-8

Capacitive point level detection in metallic vessels and pipes with build-in system PHARMadapt EPA-18

Types: NVS-061 / NVS-081

Conductive point level detection in pipes from DN15 and vessels, with hygienic thread M12 (CLEANadapt)

Types: NVS-041

Conductive point level detection in pipes from DN15 and vessels, with hygienic thread M12 (CLEANadapt)

Types: NVS-161 / NVS-163 / NVS-166 / NVS-181 / NVS-183 / NVS-186

Conductive point level detection in pipes from DN15 and vessels, mini-version with hygienic thread G1/2″ (CLEANadapt)

Types: NVS-141 / NVS-143 / NVS-146

Conductive point level detection in pipes from DN15 and vessels, with hygienic thread, G1/2″ (CLEANadapt)

Level detection and temperature measurement in one device. For tubes from DN25 and vessels. with hygienic thread G1/2″ (CLEANadapt)

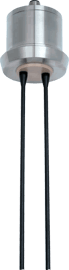

NVS-345 – Conductive multi-level detection with max. 4 electrodes

NVS-50 – Conductive multi-level detection with max. 4 electrodes

Conductive multi-level detection with max. 5 electrodes, sensor head in PFA (non-hygienic)

External electonic control devices for conductive point level sensors of the NVS series

Precise point level detection is an essential basis for maximum process and application reliability. This prevents efficiently pumps from dry running or vessels from overflowing and helps to automate filler applications with minimum product loss due to precise full / empty signals. With its comprehensive product range in this applications sector Anderson-Negele level sensors always offer the most suitable measuring technology for virtually all hygienic applications and even for foaming or pasty media.

While the measuring electrode of the sensors and the vessel wall form the capacitor plates, the liquid becomes the dielectric medium. Due to the superior permittivity (dielectric constant) value of the medium compared to air the capacity increases by growing coverage of the electrode. The alteration of capacity is measured by the electronic devices of the capacitive level sensor and transformed into a switch command.

A point level switch detects that a defined filling level has been reached and emits a switch signal for process control. As a manufacturer of sensors operating with a wide variety of measurement technologies Anderson-Negele provides tailored solutions for beverage and food producers and the pharmaceutical sector.

The capacitive or the conductive measuring method are mostly used for the point level applications.

The capacity of a condenser is determined principally by three factors. The distance and the dimension of the electrode surface and the type of dielectric fluid between the electrodes. In case of capacitive level measurement by means of a probe only the type of dielectric fluid is crucial.

Foaming and adhesive products in food and drink production processes make a real challenge for the level sensor technology.

The solution by Anderson-Negele:

The capacitive operating mode requires a full coverage of the PEEK sensor tip by the medium. This fact guarantees that the point level sensor doesn’t respond to foam or adhesions but only reacts if the actual infill level of the medium reaches the position of the sensor tip.

Single or Multi-rod versions, specific coatings or versions for strongly adhesive media ensure that even with most difficult products such as cream, kechtup, oils, alcohol and many others there is always a reliable and precise point level measurement solution.

Point level control is often combined with Flow Control and Continuous Level Control. Juxt click to discover our solutions in these product categories.

Copyright © 2022 Anderson-Negele