In many applications, weighing systems for content measurement offer a more practical and precise solution than other level technologies. With a field-proven sensor program, we now also offer precise, robust and efficient solutions in this measuring ...

The Allrounder: Dynamic content monitoring through precise weight measurement, for all industrial applications

The Hygienic Specialist: Dynamic content measurement through precise weight measurement, polished design for all hygienic applications

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement, extremely robust design with cage

Bolt-on dual-axis shear force sensors for all types of vessels with metal supports and skirted silos

Bolt-on strain gauge sensors for vessels with metal substructures and skirted silos

The fully integrated all-in-one weighing system for all types of large containers and silos

Display and programming device for all Anderson-Negele weighing systems with Half-Bridge or Full-Bridge Technolgy, with indication, calibration and configuration function.

When do Weighing Systems make sense? In many process vessels, storage tanks and silos, precise content detection is a particular challenge. Classical measuring systems such as hydrostatic sensors, potentiometric probes, or radar often have their limitations. In some application environments, they are not precise, fast or flexible enough, not practical for technical reasons or not economical.

This is especially the case with:

They are new to Anderson-Negele, but have been field-proven for decades: Weighing systems for sanitary and non-sanitary applications, wet and dry goods, process and storage containers.

Thanks to a variety of measuring systems, solutions are available for almost all requirements.

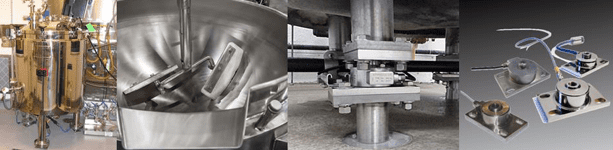

The Load Disc weighing systems dynamically measure the contents of process or storage containers and precisely indicate even the slightest changes in weight. They are firmly bolted between the container feet and the foundation. The very low overall height ensures stability and tilt resistance. Transverse forces caused by agitators are compensated. Their compact, sanitary design with polished surfaces and high water resistace (NEMA / IP) class that they can be cleaned in accordance with sanitary requirements in food or pharmaceutical applications.

In addition to the Load Disc pressure measuring modules, which are mounted between the vessel and the foundation, a tension measuring module is also available . The Tension Cell is inserted between the suspension and the container body in suspended containers.

The solid bolting makes Load Stand II a structurally load-bearing integral component and connecting element between the container base and the foundation, and ideal for large containers, tanks and skirted silos.

Thanks to the extremely long service life of the strain gauge cells and their easy replaceability, there is practically no limit to the service life of a Load Stand II.

Microcell® and L-Cell® are extremely long-lasting, reliable, and compact sensors for cost-efficient inventory measurement in all types of vessels, either with a leg support structure or skirted silos. This avoids measurement inaccuracies reliably due to material characteristics like the angle of repose, rat-holing, bridging, moisture content, compaction.

Depending on the vessel type, the sensors are mounted with bolt-on technology on the structural support members and shear beams support or structural skirt.

In our webinar recordings you can get a fast and easy overview on our Weighing Systems solutions.

Copyright © 2022 Anderson-Negele