Precise flow control is the basis for safe and efficient processes in almost all applications. But when is a flow meter, a flow switch, the electro-magnetic, turbine, ultrasonic or calorimetric technology better? Find the best solution for your application ...

Compact magnetic-inductive flow sensor for media with minimum conductivity >5 μS/cm | With IO-Link

Magnetic-inductive flow sensor with very high accuracy for media with minimum conductivity >5 μS/cm

Certifiable magnetic-inductive flow and volume measurement of media with a minimum conductivity >5 µS/cm

Compact Coriolis Mass Flow and Density meter for for hygienic applications, even for challenging processes and liquids

HM-E – Non-contact pulse-measurement of flow rate and volume of media without conductivity

HMP-E – Non-contact pulse-measurement of flow rate and volume of media without conductivity

FTS-141 – Calorimetric flow switch for pipes from DN 25 for aqueous media (water content >50%)

FTS-741 – Calorimetric flow switch for pipes from DN 25 for aqueous media (water content >50%)

FTS-141P – Calorimetric flow switch for pipes from DN 25 for aqueous media (water content >50%)

FTS-741P – Calorimetric flow switch for pipes from DN 25 for aqueous media (water content >50%)

When 40+ years of Mag Flow Expertise meet 90+ years of Hygienic Sensor Competence:

After the integration of the GEA Diessel magnetic flow meter business, its sensor range, and specialized staff, Anderson-Negele have become your hygienic instrumentation specialists with the “FLOW-HOW”.

Flow meters for the precise determination of the quantity, volume or speed of media flowing into systems are the basis for safe and efficient processes in almost all applications in the food and beverage industry.

Typical examples are

Flow switches are used in almost all production plants to monitor the plant’s technical safety and the correct operation of the processes. A possible malfunction of a pump, a closed valve, or a misdirected medium is reliably detected and signaled.

With various technologies, Anderson-Negele flow sensors and flow switches offer a suitable measuring system for every application, every process, and every fluid:

Measuring the quantity or volume with the highest accuracy can directly save costs due to loss prevention and better use of resources. Indirectly a cost reduction is achieved by recipe optimization and improved control of the blending process. The specified quantities of the valuable resources are precisely adhered to so that the final product can be produced in an optimal and reproducible way in precisely the desired quality.

Flow switches are primarily used to control costs by minimizing risks. If a medium does not flow in a process due to a system error, this can cause significant damage. Pumps may run dry, CIP processes may not run according to specifications, mixing, and filling processes may be disrupted, all of which can lead to high plant or product damage. With flow switches, such malfunctions are immediately detected, and countermeasures can be initiated.

Essentially, the Anderson-Negele product line offers two measuring principles for the flow measurement of liquids: magnetic-inductive flow measurement and turbine flow measurement. For Flow Switches Anderson-Negele also offers two versions, either with Calorimetric or with Ultrasonic measuring principle. Scroll down to find out details on each of these technologies:

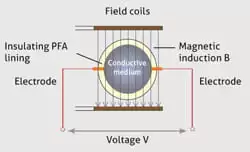

This measuring principle is based on Faraday’s law of induction. A constant magnetic field is generated by two field coils arranged vertically in the measuring body. The induced voltage is measured horizontally via two stainless steel electrodes. This voltage is generated, i.e., induced by the flowing, conductive medium. It is directly proportional to the flow velocity and can be converted directly into flow volume. The measured values determined are available as a counting pulse, as a 4…20 mA standard signal and, in the case of IO-Link devices, also digitally.

Starting from a minimum conductivity of > 5 μS/cm, the induced voltage can be measured. This technique is suitable for media such as milk, cream, beer, ketchup, sauces, creams, mash, molasses, yogurt, concentrates, cleaning media, and many others.

This measuring principle works with a non-contact pulse measurement. A turbine sits directly in the liquid flow and is set in rotation by its rotor blades through the flow movement. A signal probe generates an electromagnetic field via an oscillating circuit. The rotating rotor interacts with this field to create an induction current, which can be precisely measured and output by the probe.

Turbine flow meters with non-contact pulse measurement are the reliable, precise, and economical alternative to mass flow meters or magnetic-inductive flow meters. This measurement technology is also suitable for non-conductive, aqueous media such as filtered fruit juice or beer, alcohols, light oils, salt solutions, cleaning media, and acids, but also process water, demineralized water, and WFI.

In a Coriolis flow meter the fluid is split into two tubes. An active device forces these measuring tubes to oscillate. At zero flow, the two tubes vibrate in phase with each other, the sinus waves are parallel. When flow is introduced, the Coriolis forces cause the tubes to twist resulting in a phase shift of the sinus waves. The time difference between the waves is measured and is directly proportional to the mass flow rate.

Mass and volume flow measurement: These values are calculated from mass flow rate and the density measurement.

Density measurement: The measuring tubes are vibrated at their natural frequency. A change in the mass of the fluid contained inside the tubes causes a corresponding change to the tube natural frequency. The frequency change of the tube is used to calculate density.

These measuring instruments are suitable for almost all production processes in the food and beverage industry and are particularly advantageous in applications where the density (or concentration, Brix, Plato, Proof or Baumé value) must be determined at the same time as the flow rate.

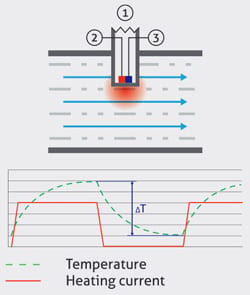

The operating principle of the calorimetric flow switch FTS is based on a temperature sensor attached to the sensor tip, which is periodically heated by a heating element. When the medium is stationary, a constant temperature difference ∆T between heated and unheated state is established. When the medium flows through, thermal energy is extracted from the heated temperature sensor, and the temperature difference changes depending on the flow velocity. In contrast to designs based on two separate temperature sensors, one of which is heated continuously, the measuring principle of the FTS with only one sensor and periodic heating enables a shorter response time due to the optimized heat transfer and the lower heat capacity.

This measuring principle is ideal for all aqueous products, including demineralized and highly filtered media such as cola and other soft drinks, filtered beer, demineralized water, as well as for media in pressure lines.

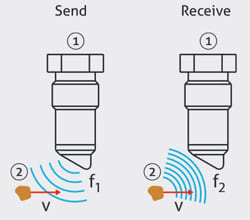

A transmitter sends ultrasonic waves into the flowing medium. This ultrasonic wave hits particles, e.g., sediments, dirt, or air bubbles moving in the direction of flow and is reflected. The receiver now sees the reflected frequency slightly shifted as the wavelength changes due to the forward movement of the reflecting particle (ultrasonic Doppler principle). The difference between emitted and received frequency is a measure for the particles’ speed of motion and, thus, also a measure for the flow velocity.

Many flow monitors are limited to aqueous media. In contrast, the ultrasonic Doppler measuring principle is ideally suited for all media with the slightest turbidity or with air bubbles. This technique can be used when other flow monitors do not work, e.g., with dough, glycol, oils and oil-based media, adhesive or viscous media, creams, but also drinking water, milk, juice (unfiltered), and CIP media.

If you want to control the entire process plant technology with a large number of measuring, control, and operating devices, the digital interface IO-Link offers significant advantages over analog technology.

With its Flex-Hybrid technology, the FMQ flow meter combines the best of two worlds: data from the sensor can be transmitted in a digital, or analog way, or parallel in both technologies. This creates a significant advantage, especially in times of technological change from today’s analog to digital IOT generation: If, for example, you currently still control a system in analog mode, but consider a conversion to IO-Link, you no longer need to make a decision. Instead of “either … or”, Anderson-Negele uses the word “and”. Simply by connecting a new cable, the sensor can be switched to digital at any time later without even touching the hardware or the settings. Installation and commissioning are extremely time- and cost-saving. For the signal transmission and the power supply itself, a three-pole standard cable without shielding is sufficient.

Copyright © 2022 Anderson-Negele