Food, Beverage and Dairy

Life Sciences

Food, Beverage and Dairy Life Sciences

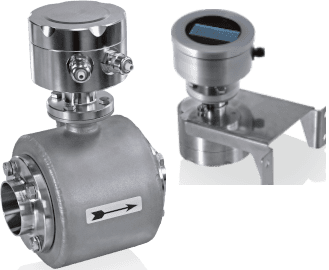

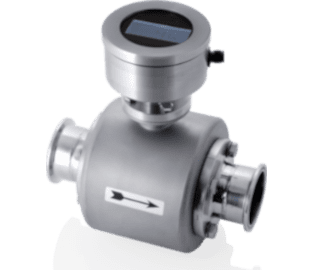

FMQ Magnetic-inductive Flow meter

Flow Sensors, CIP Controls, IO-Link

Magnetic inductive flow and volume measurement of media with a minimum conductivity >5 µS/cm | With IO-Link

Now with IO-Link: Discover the advantages in our new IO-Link Brochure!

- For liquids, mash and pastes with solids content < 5%

- Very high accuracy ±0,5 % ±2 mm/s and reproducibility also with low flow rate, ideal for dosing and filling applications

- Large selection of process adapters (optional)

- Incl. optical status indicator, optional display

- Incl. material certificate for pharmaceutical version

- 3-A conformity for version with process connection SS, TC and HH

- Compact electronics with housing in stainless steel

- Vacuum proof PFA coating for pig cleaning and maximum resistance to aggressive media

- All details about IO-Link properties, parameters, diagnostics, events and more can be found in the IODDViewer. Just click here.

- Add-On Instructions (AOI) are available at www.anderson-negele.com/aoi

Technical Specification

| Process Connection | Aseptic flange | Aseptic thread | FG hygienic flange | DIN flange | welded flange | Tri-Clamp | Varivent | SMS | Dairy tube |

| Wetted material | Stainless steel 1.4404 (316L) | 1.4435 Ra≤0.4 μm (electropolished) | Tube PFA |

| Measuring range | "0,1…10 m/s | 30…280.000 l/h" (DN10...DN100 | 1/2”...4”) |

| Accuracy | ±0,5% ± 2mm/s |

| Available versions | Compact | Remote |

| Temperature range process | Compact: 0…100 °C / 32...212 °F | Remote: 0...165 °C / 32...329 °F |

| Temperature range CIP/SIP | Compact: 130 °C / 266 °F max. 30 Min. |

| Operating pressure | max. 17 bar absolute |

| Communication | IO-Link | 4…20 mA (Flex-Hybrid) |

| Output unit | l | m³ | hl | ml | gal (US) | gal (CDN) | gal (Imp.) | lb | bbl | dm³ |

| FMQ - Benefits | FMQ has everything you really needThe electromagnetic flow meter is an extremely versatile, robust and reliable device for all conductive media. The performance spectrum is tailored to almost all applications, including dosing and filling applications.

» FMQ with IO-Link: Thanks to Flex-Hybrid technology, you can use digital or analog communication or both in parallel » Extremely compact: Minimal size of measuring body and electronics allow easy, vibration-insensitive integration into almost all applications » Extremely robust: All components are completely made of stainless steel. The magnetic field coils of the measuring system are consistently encapsulated, which guarantees permanently reliable, precise measuring results even in very harsh environments with strong vibrations or pressure surges » Extremely reliable: Completely protected against moisture, corrosion and vibrations; vacuum-proof measuring tube lining made of high-quality PFA; process temperature up to 100°C (212 °F), CIP-capable, pigging possible. » Always accurate: Automatic signal processing ensures correct measured values even when changing media (e.g. milk/CIP cleaner) » Easy commissioning and operation: User-friendly, rotatable display with optical buttons, no opening of the housing, no mechanical buttons, for quick and easy programming. Remote version optional. » Manufacturer-independent process connection: Standard aseptic flange according to DIN 11864, with O-ring (no sanitary-sensitive surface seal), pipe standard DN10...DN100 (1/2”...4”) |

| The values shown are the performance limits within the product line. The product-specific data for each individual configuration can be obtained from the product information | |

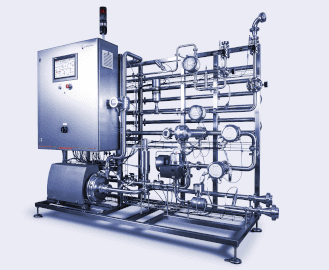

Application

Videos

Configuration with IO-Link

Special functions

Service level / Simulations

Replace Flow tube

Metering parameters

Main display batch zero

Head orientation

Factory reset

Current output

.png)

.png)

Copyright © 2022 Anderson-Negele