Only with a superior hygienic process connection a sensor can ensure efficient and reliable function. Gap-free, flush sensor integration, thermowells avoiding medium contact, pre-fabricated built-in systems and adapters in the CLEANadapt and PHARMadapt series ...

Flexible applicable, gap free process connection for pipes/vessels for hygienic sensors

Adaption for temperature measurement in pipes without process opening

Aseptical, gap free process connection for temperature/limit sensors in pipes for pipes from DN10

Gap free process connection for temperature measurement without process opening

HYGIENIC BY DESIGN™. That’s what we aspire for process adapters and sensor integration. In the production of food, beverages or Life Science products, consumer protection and safety are paramount. Dairies, Breweries, Beverage plants and the pharma industry must ensure that production facilities and processes comply with the guiding principle of hygienic design. Internationally recognised labels such as 3-A and EHEDG provide corresponding guidelines for materials, plant design and process cleaning. As a leading specialist for hygienic sensor technology, the concept of hygiene is so deeply rooted as a corporate philosophy that “HYGIENIC BY DESIGN” is even part of our company logo.

Hygiene is a critical concept in food, beverage and life science production. Equipment and facilities, as well as the integrated instrumentation, must be designed to maintain high levels of hygiene and cleanliness during the manufacturing process. The goal is to prevent contamination and ensure that the final product is safe for consumption.

There are several key factors that are typically included in hygienic design. First and foremost, all equipment and surfaces must be designed in such a way that they can be cleaned before each use. In dairies, this is usually done by CIP (Cleaning In Place) systems. To fulfil this requirement, sensors and other equipment must be installed in a self-draining position and without dead spaces. Dead spaces may be found in process connections of sensors, valves, pumps, and other equipment components, but also where piping is connected, in corners and other hard-to-reach areas within processing equipment.

Another important principle of hygienic design is the use of high-quality materials that are free of cracks or crevices where bacteria or other microorganisms can thrive. They also must resist to corrosion and multiple cleaning cycles with aggressive cleaning agents like acids and lye. By ensuring that all equipment used is made of materials like high-quality stainless steel 1.4404 / AISI 316L with a surface roughness equal or better than Ra ≤ 0.8 μm, or of FDA-approved PEEK, processors can ensure hygienic design and cleanability also over long time periods.

Institutions such as 3-A SSI (Sanitary Standards, Inc., a not-for-profit corporation) or the EHEDG (European Hygienic Engineering and Design Group) issue corresponding guidelines according to which engineers have to design the plants, and to which sensor manufacturers can certify their products. Anderson-Negele sensors are developed exclusively for use in hygienic applications. In terms of materials and product design, they are therefore engineered specifically to meet these requirements, and have the corresponding certificates. Nevertheless, when installing the sensor, the mounting position must be self-draining, avoid horizontal surfaces and pooling of liquids, be easily accessible for maintenance and inspection, and facilitate CIP cleaning.

With appropriate system planning, this can be achieved with all common process connections. However, due to its extensive experience in this field, Anderson-Negele has also developed special process connection systems with a wide range of different Process Adapters and Process Connections for food, beverage and biopharmaceutical equipment based on the guiding principle “Hygienic By Design”.

Besides the systems CLEANadapt and FLEXadapt for the Food & Beverage industry we also offer process connections that were specially developed for the superior requirements of pharmaceutical and life-science applications: PHARMadapt ESP, PHARMadapt EPA and CPM.

CLEANadapt – is a hygienic system that can be used with almost every sensor from Anderson-Negele. “Hygienic by Design” – this means sensor integration in all food applications in a simple and safe manner. For that purpose the universal CLEANadapt installation system offers a variety of adapters and fitting components for almost all common sensor types.

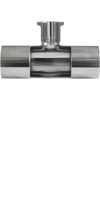

In the CLEANadapt system, which has been specially developed for food applications, flow-optimised pipe Tees, weld-in sleeves or adapters for existing process connections are easily integrated into tanks or pipes and the sensors are screwed in.

· Hygienic sealing principle: A conical surface on the sensor connection piece is pressed against the sealing edge of the adapter through defined screw fixation. This results in a simple, safe and permanent, maintenance-free and hygienic adaptation without dead legs, elastomers, seals or Teflon tape

· Three thread sizes, universal application: With the dimensions M12, G½” and G1″, sensors for temperature, point level, continuous level, flow, pressure, conductivity and turbidity can be integrated easily

· Simple, flexible installation: Weld-in sleeves for a wide range of installation situations in tanks and pipes. Pipe Tees for safe and hygienic welding (orbital method) in pipes from DN15 to DN100. Process adapters for direct mounting on existing process connections such as Tri-Clamp, Varivent and many more.

· Original components ensure safety: Only Original welding sockets are always provided with the Anderson-Negele logo and guarantee the best possible system tightness.

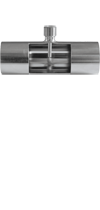

FLEXadapt ESF – Temperature measurement in pipes from DN20 on and vessels without direct contact between the sensor and the medium. Sensors can be removed without opening the process line. In addition to pre-fabricated build-in systems, adapters even for vessels as well as a full range of compatible temperature sensors are available. With the FLEXadapt ESF installation system, a thermowell is permanently installed in the process. The slim tip of the sensor is inserted into this thermowell and maintained in contact by a spring. It is therefore not in direct contact with the medium. The sensor can be removed at any time for recalibration or replacement, without opening or stopping the process, and consequently without downtimes of the plant.

· Tailored to requirements: Special design for food applications

· Variable: Installation in tanks using welding sockets, welding sleeves or adapters. Installation in pipes using tees or elbows with integrated thermowells

· Ideal for Retrofitting: Screw-in socket for easy conversion of existing G1/2″ process connections

· One for all: One sensor type with the same probe length can be used for differing pipe widths, thus minimizing spare parts inventory and planning requirements

· Reliable: Spring-mounted tip for perfect contact

· Maximum hygiene: No product contact = No risk of contamination by previous products, foreign bodies and germs via the sensor

· Easy to clean in CIP/SIP: design without dead-legs

PHARMadapt ESP – Temperature measurement in pipes from DN10 on and vessels without direct contact between the sensor and the medium. With the ESP installation system, an thermowell is permanently installed in the process. The slim tip of the sensor is inserted into this thermowell and held in contact by a spring. It is therefore not in direct contact with the medium. The sensor can be removed at any time for recalibration or replacement, without electrical disconnection and without opening the process, and consequently without necessity to shut down the plant or to stop the process.

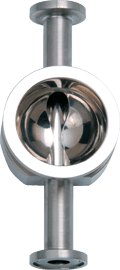

PHARMadapt EPA – Aseptical, gap free process connection for temperature measurement and limit detection in pipes from DN10 on. Sealing to process results from exchangeable O-rings. Especially in pipes with a small nominal diameter, the hygienic installation of a temperature or point level sensor is often difficult to realize.

The PHARMadapt EPA installation system, specially developed for pharmaceutical applications, makes this integration simple and safe: the flow-optimized pipe tees are simply and reproducibly welded in and the sensors are inserted by means of a clamp connection.

CPM – Gap free, front flush pressure measurement in pipes with small diameters from 1/4″on with standard pressure sensors. For high-precision and hygienic pressure measurement, the pressure diaphragm must be integrated into the process as flush as possible and without dead space. This is a particular challenge for pipes with small nominal diameters. Here, the CPM installation system offers a process connection that is easy and safe to install and offers unique advantages due to its special design.

· Zero dead-leg installation with perfect diaphragm position: Due to the design of the CPM adapter and the extension of the sensor nozzle, the pressure diaphragm sits inline precisely at the height of the media feed-through. This results in an absolutely flow-optimized and hygienic process adaptation. Due to the design of the CPM, dead spaces such as with Tees or weld-on sockets are excluded.

· Pressure sensors with standard sizes: Pressure sensors with standard diaphragm diameters of 22 or 38 mm are also used for the smallest nominal pipe diameters from ¼”. Measurement tolerances such as those for smaller diaphragm diameters are avoided by design.

· Easy installation: The CPM adapter is simply fixed in the process with Tri-Clamp or can be welded safely and hygienically with AWF welding collar in orbital process. The pressure sensor itself is sealed with an O-ring and mounted with a standard 1½” clamp.

Copyright © 2022 Anderson-Negele