Life Sciences

Life Sciences

Life Sciences

CPM

Adapters & Fittings

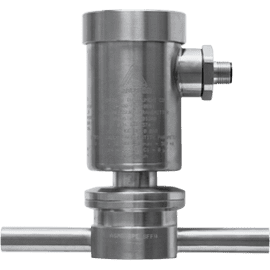

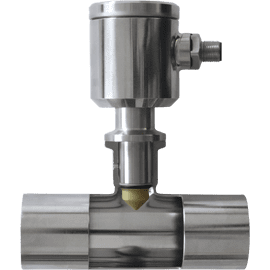

Gap free, front flush pressure measurement in pipes with small diameters. Suitable for pipes from 1/4″ on.

For high-precision and hygienic pressure measurement, the pressure diaphragm must be integrated into the process as flush as possible and without dead space. This is a particular challenge for pipes with small nominal diameters.

Here, the CPM installation system offers a process connection that is easy and safe to install and offers unique advantages due to its special design.

- Zero dead-leg installation with perfect diaphragm position: Due to the design of the CPM adapter and the extension of the sensor nozzle, the pressure diaphragm sits inline precisely at the height of the media feed-through.

- Pressure sensors with standard sizes: Pressure sensors with standard diaphragm diameters of 22 or 38 mm are also used for the smallest nominal pipe diameters from ¼”. Measurement tolerances such as those for smaller diaphragm diameters are avoided by design

For an overview on all advantages and benefits of our process connections we recommend our brochure “Hygienic installation systems for Pharma Applications”.

You can find the brochure here.

Technical Specification

| Process Connection | Process connection CPM | CPM Mini - Installation with Tri-Clamp | butt weld AWF |

| Wetted material | Stainless steel 316L | Option: Hastelloy |

| Available versions | For pressure transmitters L3 | MPP | PF | HA - For pressure gauges EK | EM | EP |

| The values shown are the performance limits within the product line. The product-specific data for each individual configuration can be obtained from the product information | |

Videos

.png)

.png)

Copyright © 2022 Anderson-Negele