Intelligent sensing technology can help to ensure reproducible product quality throughout the production process, automate processes, minimize energy and resource consumption, and avoid production downtime and food waste. As diverse as raw material quality, recipes and processes in production of dairy and cheese products are, so are the demands on measurement technology. That‘s why we offer a complete sensor range, each with a wide range of variants and options. You get exactly the performance you want for every application and every business type, from regional producers of milk and cheese specialties to industrial dairy plants – no more, no less.

Our Tip: Check which of the applications in this overview you use in your operation, take a look at the product portfolio we offer from a single source, and build your “dream sensor system”. We will be happy to help you find the optimal solutions. Just contact us.

Click here to download brochure

After the raw milk has been received, the product is stored in a buffer tank until it is processed. When installed in insulated tanks, the sensors must take the wall depth into account. In the case of external tanks, they must also be able to withstand climatic conditions.

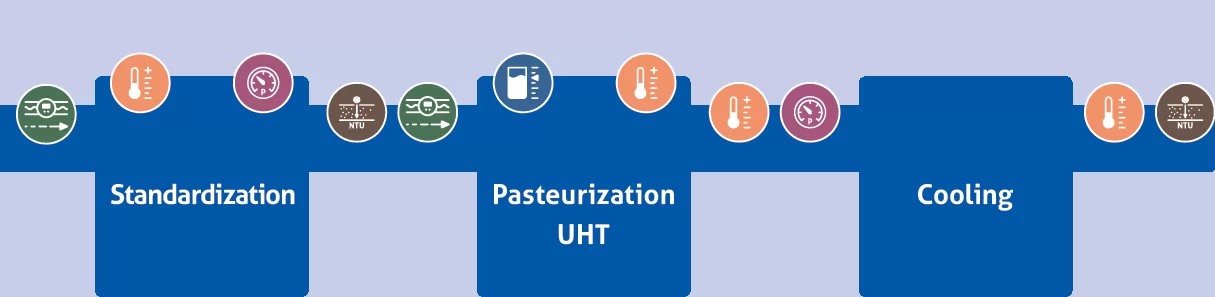

Various systems such as separators or centrifuges are used to separate cream from skimmed milk and to remove impurities at the same time.

Homogenization is only possible with controlled pressure.

To produce milk or dairy products with a desired fat content, cream and homogenized skim milk are mixed together again.

The products are made shelf-stable by heating them to precisely specified temperatures for a short time.

At many points in the dairy process, the product needs to be cooled to a certain temperature. Heat exchangers help to achieve this with the lowest possible energy consumption.

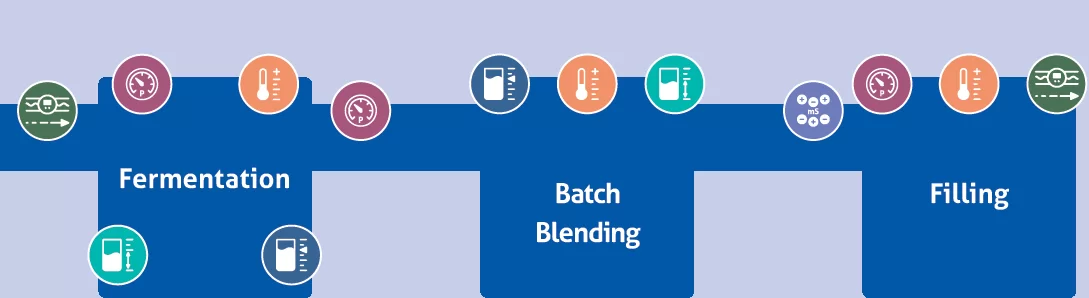

Many dairy products are fermented, often in aseptic vessels under pressure.

In both batch processes and continuous processes, you need to be able to control your recipes precisely.

Different filling systems are used for bottles, tanks, bag-in-box or other packaging. In bottle cleaning, sensors monitor the quality of the cleaning and the cleaning liquids.

Depending on the cheese process and the plant equipment, different sensors can be used to monitor the production of cheese specialties.

In this process, the moisture is removed from the milk or whey in several drying cycles.

Fresh water control is crucial for high end product quality.

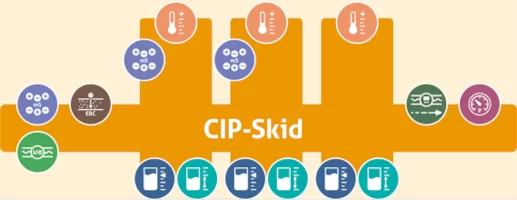

CIP systems for a beverage production can be central or decentralized. For improved efficiency, the return flow of the media can be monitored for the degree of contamination by analysis sensors. This allows the expensive cleaners to be automatically returned to the batch tank when the degree of contamination is low, and low-contaminated rinse water can be re-used for pre-rinsing in the next process. With conductivity measurement the cleaner concentration can be monitored and controlled automatically. In our “Solutions” / “CIP Control” section, you will find all the details on how intelligent sensor technology can contribute to resource-efficient and reproducible CIP processes.

For a producer, this not only means an ecological and ethical component, but also pays off in hard cash. Every liter of wasted resources means lost value. And every liter of product that ends up in the gutter even causes additional expense in wastewater treatment. Areas where intelligent instrumentation can help prevent losses include phase transition between two media, insufficient product quality due to processes that are not optimally controlled, inaccurate level control in storage or process vessels, and a CIP process that is not automated.

Our tip: Examine all your processes for their optimization potential. We will be happy to help you on site. Just contact us.

Every production process has its specific requirements. In batch processing, instrumentation in the process vessel is often in conflict with moving parts; here, factors such as installation situation, flushness, suitability for insulated tanks and vibration resistance are important. In the continuous process, sensors are your “eye in the pipe”, your view into the process. Here, for example, short response times, auto-adaptation to media changes or automated error alarms are important success criteria.

Our tip: Thanks to a large selection of sensor types and configuration options, our product range offers a suitable technology for most requirements and production methods. Tell us your specific application and we will be happy to help you select the best solution.

Anderson-Negele products are designed and built exclusively for food applications. Therefore, they meet all requirements for hygiene-sensitive production areas from the very beginning, as evidenced by certifications such as 3-A and EHEDG. This means maximum hygienic protection of your products, easy equipment cleaning, and ultimately maximum peace of mind and enjoyment for your customers.

Our tip: When it comes to process connections, we also offer a wide range of solutions that ensure hygienic integration into your plants through dead space-free design and superior material and surface quality. With CLEANadapt and FLEXadapt, we have specially developed process connection systems that simplify hygienic installation and operation and can even be retrofitted.

Most Anderson-Negele sensors with IO-Link are equipped with “Flex-Hybrid Technology“, i.e. digital IO-Link and analog 4…20mA communication in parallel. Even if the plant is operated analog, you can commission all sensors with only one software via computer. Specific programming can be easily transferred to other sensors by copy-paste. And in the case of a sensor exchange, the entire individual programming is transferred simply by plugging it in.

Our tip: With Flex-Hybrid Technology, you already have advantages in installation and commissioning. And if you switch to digital IO-Link technology later, there is no need for new sensors. Find out all about our IO-Link solutions in our “Solutions / IO-Link” section or at the IO-Link website.

Many of our sensors are available as “remote” version. The actual measuring device and the electronics unit with operating display and transmitter are separated. This protects the electronics from vibrations and high temperatures and can significantly increase the service life. It is also extremely practical, as you can simply place the electronics and displays where it is most convenient and accessible for easy and quick reading or programming.

Our tip: Get the perfect overview of all processes and vessels without having to bend down or walk around and ensure easy programming and longer service life with remote sensors.

Many customers use our sensors under a wide variety of everyday requirements. Discover how other dairies or cheese producers are successfully overcoming their challenges with Anderson-Negele sensors. Our case studies show examples where we have been able to help our customers achieve their goals through application consulting, product testing or technical support. You can find our case studies online here.

Our tip: Our case studies can give you a small overview of the variety of applications where intelligent instrumentation, used correctly, can make your work easier, improve quality and reduce costs. We are happy to meet you on site to find answers to your questions on site. Please contact us!

They are indispensable in almost every step of the dairy or cheese production and for CIP control. That’s why we offer our Temperature sensors in 2 standards (Big and Mini), with a comprehensive performance range and an almost infinite variety of customization, process connections and options.

Keep optimum control of process or vessel pressure at all times. Thanks to many sensor options you always find the most suitable solution for every application, every requirement and every desired pressure measuring range, be it as an on-site display or for PLC connection.

Different temperatures, different vessel shapes, sometimes pressurized, different densities, differently foaming media, different turbidity and solids contents – highly different requirements and dynamic changes influence the control of the filling level of your various vessels and containers. However, at any moment you need to know exactly how much product is in the vessel or ensure that a vessel does not overflow or run dry. That’s why we offer different measuring techniques and many different designs and options, so that you get the best solution for every purpose and application.

Here’s how to keep control of your products, monitor your blending, and ensure the reliable operation of your plant: Precise flow control with electromagnetic flow meters. Flow monitors give an alarm when the flow stops and are ideal for monitoring pump systems, filters, cooling circuits, the CIP return or for detecting misdirected media.

Turbidity sensors can be used to clearly distinguish between liquids based on their clarity, but also on their fat content. Do you want to safeguard your product quality by precisely monitoring the degree of turbidity? Control your separator optimally? Control the phase transition of milk, cream and whey with maximum efficiency? Reuse slightly contaminated CIP media and thus save costs? Minimize wastewater costs through contamination monitoring? Then our turbidity sensors are your perfect solution.

For active, automated phase transition, control of the CIP return of acid / caustic / water and concentration control of the CIP cleaners: ILM-4, your safeguard for process reliability.

For a wide range of sensor types, our connection systems offer a consistent hygienic installation concept: High-quality stainless steel or PEEK for all wetted components, simple and secure screw connection or even installation in thermowells for sensor removal without disrupting the process.

Turn your vessel into a precision scale. When integrated level control systems fail, weighing systems come into their own. Load Discs give you full control of the contents, even with interchangeable containers for ingredients or additives.

Your key to greater efficiency: sensors with IO-Link in Flex Hybrid technology. These make planning, commissioning, and operating your plants easier, faster and more flexible. For existing analog plants, Flex-Hybrid means easier programming, sensor changes with “plug-and-play”, and if you upgrade to IO-Link control at some point, the sensors are changed over just by plugging them in.

Explore how Anderson-Negele can support your dairy and cheese production with innovative sensor technology.

Check at our product portfolio and assemble your “desired sensor technology” for your corporate. Here you can contact us.

Copyright © 2022 Anderson-Negele