Turbidimeter ITM-51 replaces laboratory fat control

Dairy

In this Indian dairy, milk products with different fat contents are produced and filled. To ensure that the correct product gets into the sales packaging, each batch used to undergo a laboratory test to determine its fat content. The time required for the laboratory tests and the damage in the event of an incorrectly filled product were considerable. This situation was overcome by an ITM-51 turbidimeter. Since this also reacts sensitively to different fat contents in the product, quality control can now be carried out automatically via an inline application in the process itself.

Customer

Advantages in the Application

» Turbidity measurement with fully automatic function: Manual sampling and laboratory test can be completely replaced by an ITM-51.

» Real-time error alarm: In case of a faulty fat content, the turbidity sensor gives an alarm signal within < 1 second so that the filling process can be stopped

immediately.

Application Detail

As in many dairies, the fat is extracted from the milk in an initial processing step and later added back in batches specifically for each end product. This allows various dairy products with different fat contents to be created from the raw milk.

The individual batches are then filled into specific packaging on which the fat content is indicated. To prevent incorrect products from entering the packaging, a sample used to be taken at the start of each filling process and analyzed in the laboratory. This additional step was very time-consuming for the operating personnel.

To save time, the filling process was continued in the meantime. If a faulty value was now detected in the laboratory analysis, the batch already filled had to be completely disposed of, which in turn caused production damage with corresponding costs.

The Anderson-Negele Solution

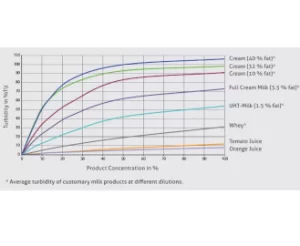

The ITM-51 turbidimeter can measure not only the relative turbidity in a product, but also the fat content in milk. For each product, a preset for the turbidity values at which an alarm signal is to be issued can be programmed in on the sensor itself. To do this, a sample is taken, and the laboratory value determined is used as the setpoint. As the diagram below shows, the %TU values of milk with different fat contents differ significantly, so that the turbidity measurement can achieve virtually 100 % reliability for this quality control.

The inline measurement completely eliminates the need for sampling and laboratory analysis and the time and expense required for these.

In addition, the ITM-51 gives an alarm signal in real time due to its extremely short response time of only 0.75 seconds.

This means that filling can be stopped without any loss of time and the loss of product that previously was filled incorrectly can be avoided.

The ITM-51 is front-flush and can be easily integrated into existing skids in a fast and cost-effective manner using a hygienic clamp or screw process connection.

Copyright © 2022 Anderson-Negele