Product News

Content control with weighing systems

27 Oct 2021

In many process vessels, storage tanks and silos, precise content detection is a particular challenge. Classical measuring systems such as hydrostatic sensors, potentiometric probes, or radar often have their limitations. In some application environments, they are not precise, fast or flexible enough, not practical for technical reasons or not economical.

This is especially the case with:

The solution: turn your container into a precision scale

They are new to Anderson-Negele, but have been field-proven for decades: Weighing systems for sanitary and non-sanitary applications, wet and dry goods, process and storage containers.

The inventory control by weight measurement

Thanks to a variety of measuring systems, solutions are available for almost all requirements.

Weighing modules Load Disc

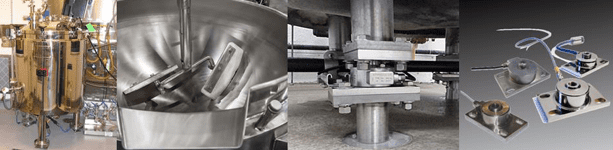

The Load Disc weighing systems dynamically measure the contents of process or storage containers and precisely indicate even the slightest changes in weight. They are firmly bolted between the container feet and the foundation. The very low overall height ensures stability and tilt resistance. Transverse forces caused by agitators are compensated. Their compact, sanitary design with polished surfaces and high water resistace (NEMA / IP) class that they can be cleaned in accordance with sanitary requirements in food or pharmaceutical applications.

In addition to the Load Disc pressure measuring modules, which are mounted between the vessel and the foundation, a tension measuring module is also available . The Tension Cell is inserted between the suspension and the container body in suspended containers.

Applications:

Further benefits

Load modules Load Stand

The solid bolting makes Load Stand II a structurally load-bearing integral component and connecting element between the container base and the foundation, and ideal for large containers, tanks and skirted silos.

Thanks to the extremely long service life of the strain gauge cells and their easy replaceability, there is practically no limit to the service life of a Load Stand II.

Applications:

Further benefits

Bolt-On Weighing Cells

Microcell® and L-Cell® are extremely long-lasting, reliable, and compact sensors for cost-efficient inventory measurement in all types of vessels, either with a leg support structure or skirted silos. This avoids measurement inaccuracies reliably due to material characteristics like the angle of repose, rat-holing, bridging, moisture content, compaction.

Depending on the vessel type, the sensors are mounted with bolt-on technology on the structural support members and shear beams support or structural skirt.

Applications:

Further benefits

What’s the elephant doing here?

Anderson-Negele’s load cells of the Kistler-Morse brand have been sold in select markets for decades. KIMO is our brand ambassador for this new product line. KIMO stands for endurance, robustness and durability. In other words, characteristics that our load cells have been proven to meet, with 20 million cycles fatigue life and 200% overload protection.

You want more information?

For more details on the respective weighing systems please check out the product pages:

or have a look at our videos from our webinar presentations:

You want to know whether our weighing systems can also help you save costs, make processes more efficient and improve your quality in your applications? We will be happy to advise you individually.

Simply contact us:

Copyright © 2022 Anderson-Negele