Product Finder

Product News

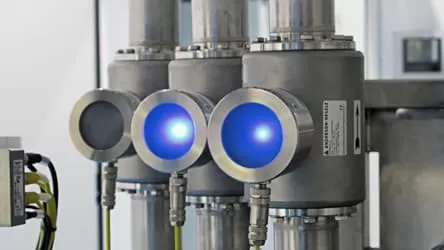

The all-rounder for reliable flow measurement: FMQ with IO-Link

FMQ has everything you really need for precise flow measurement. Now with IO-Link.

22 Feb 2021

Reliable flowmeters for the precise measurement or control of delivery are the basis for efficient and profitable processes in almost all applications in the food and beverage industry. Typical examples are

- precise dosing when mixing food or dairy products

- recipe control for mixed beverages, juices, and soft drinks

- the monitoring of production processes in breweries or CIP systems

- high-precision control of filling operations

FMQ - The compact & affordable all-rounder The electromagnetic flowmeter FMQ is an extremely versatile, robust, and reliable device for all types of liquids, slurries, and pastes with a minimum conductivity of > 5 μS/cm. It has already been a very proven product from the Anderson-Negele sensor portfolio for hygienic applications for several years. The performance range with a measuring accuracy of ±0.5% ±2mm/s and a measuring range from 30 l/h to 640 000 l/h is tailored to almost all applications, including dosing and filling applications.

The electronics have now been supplemented by the digital interface IO-Link in Flex-Hybrid technology in a product upgrade. On the other hand, FMQ, just like its "big brother" FMI, which is equipped with even higher measuring accuracy and extended electronics variants, is now available as a remote version with detached electronics.

Now with IO-Link: FMQ with Flex-Hybrid Technology (IO-Link + 4…20 mA) Flex hybrid technology with IO-Link and 4...20 mA combines the best of both worlds: Data can be transmitted from the sensor in digital, analog, or even parallel mode. The bidirectional communication enables status control at any time and preventive maintenance to avoid production downtimes. Installation and commissioning are time- and cost-saving thanks to plug-and-play technology, and the "Smart Replace Design" with automatic detection, configuration, and parameterization make sensor replacement easier than ever before.

Proven and field-tested for lasting precision

- Extremely compact: The reduced size of measuring body and electronics allows easy, vibration-resistant integration into almost all applications.

- Extremely robust: The magnetic field coils of the measuring system are encapsulated, which guarantees permanently reliable, precise measuring results even in very harsh environments with strong vibrations or pressure surges.

- Extremely reliable: The sensor is made entirely of 1.4404 stainless steel and is consistently protected against moisture, corrosion, and vibration. The measuring tube lining made of high-quality PFA is vacuum-tolerant and also suitable for cleaning systems with pigging. FMQ is designed for a process temperature of up to 100 °C and CIP-capable up to 130 °C for max. 30 minutes.

- Always correct: Integrated, automatic signal processing always ensures a correct measured value, even when changing media (e.g., milk/CIP cleaner).

- Extremely simple commissioning and operation: User-friendly, rotatable display with optical buttons for quick and easy programming without opening the housing.

Flexible and easy installation, with optional remote version Thanks to the manufacturer-independent process connection with standard aseptic flange, FMQ enables easy, hygienic installation according to 3-A standards for all pipe standards from DN10 to DN150. The rotatable electronics housing with an illuminated graphic display guarantees optimum alignment and readability of the screen for all installation situations. An optional remote version is now available, where the electronics unit can be installed at a distance of up to 10 metres from the sensor.

Thanks to its needs-based performance spectrum, FMQ is the most efficient and cost-effective option for a wide range of applications. If more advanced specifications are required for applications, the FMI electromagnetic flowmeter is the alternative high-end version for applications with a higher demand for accuracy: the increased measuring accuracy of ±0.2% ±1mm/s is ideal for high-precision applications, and the more versatile electronics offer even more options and communication interfaces such as Ethernet IP or Profibus.

Copyright © 2022 Anderson-Negele