Product News

Butter oil separation process with turbidity measurement

10 Aug 2020

In production, processing and packaging of butter, the processing equipment is regularly cleaned and remaining butter residues are washed out with pre-tempered water to ensure reliable hygienic production.

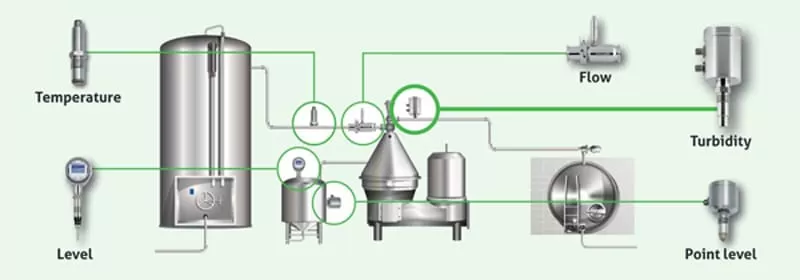

From this mixture, high-purity butter oil can be separated as a valuable raw material. An important instrument for its automated, economical and high-quality refinement is the ITM-51 turbidity sensor with a measuring range perfectly adapted to this application. In addition, sensors for flow rate, point level and temperature that match perfectly the specific medium support process control for maximum system efficiency and reliability.

The water-butter oil mixture from the plant rinsing process is pumped into a stacking tank in which natural phase separation already takes place. In a separator the butter oil phase should then be concentrated to a refinement degree of 99.5%. However, visual control during phase separation did not allow sufficient accuracy for the final product. Continuous sampling offered better quality, but this required a lot of manpower and proved to be very cost-intensive.

Finally, automated phase separation based on high-precision turbidity measurement of the butter oil mixture with the ITM-51 turbidity sensor proved to be the most efficient method for ensuring consistently high and verifiable production quality in practical operation.

Click here to read the full application report.

Copyright © 2022 Anderson-Negele