Product News

How to Choose the Best Level Sensor for Your Food & Beverage Process

4 Sep 2024

Optimizing resource efficiency in the food and beverage industry requires precise and continuous control of fill levels, volume, or mass in all storage, maturation, or process containers. Given the variety of technologies available choosing the right level sensor can be a challenge. Level measurement systems like hydrostatic level measurement, potentiometric level measurement, and weight measurement have proven to be exceptionally reliable for the stringent demands of hygienic processing.

But how do you know which level measurement system best fits your specific application?

Download our new whitepaper to learn more about choosing the right level sensor and how each measurement method is suitable for different applications in the food and beverage industry.

Level Sensors: Making the Right Choice for Hygienic Processing

The suitability of level measurement methods for hygienic processing depends on a number of different factors. The most important are:

- Type, size, shape, material and orientation (vertical / horizontal) of the vessel

- Required measuring accuracy

- Material properties of the media (liquid, pasty, bulk material, adhesive, foaming, conductive / non-conductive, carbonized, with turbidity or solids content…)

- Media temperature and its dynamic changes

- Media density and its dynamic changes

- Changing media or always the same medium in the process / tank

- Location (outside, inside) and climatic requirements (condensation / humidity) for the measurement technology

- Pressure environment (atmospheric pressure, pressurized tank / differential pressure measurement)

- Data output (indication on display, communication analog / digital / logging system)

- Installation, accessibility, and maintenance requirements (process connection / service life / reparability)

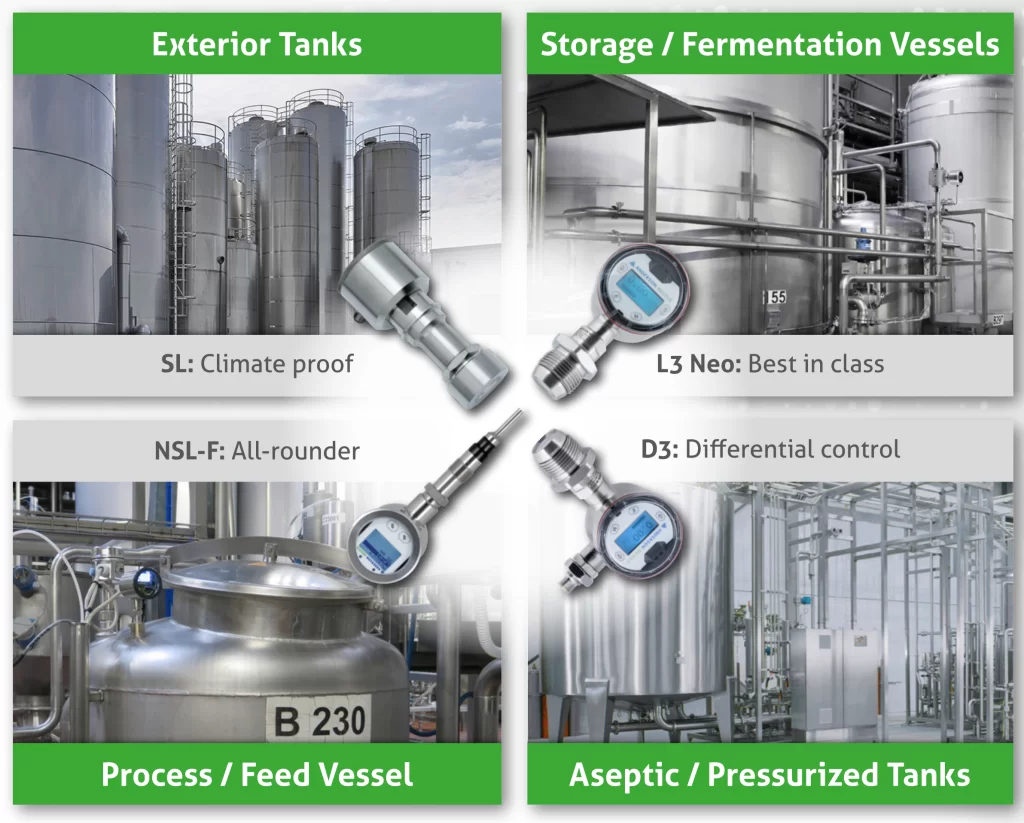

Overview of Applications and Level Measuring Systems

To meet the diverse requirements of our customers and provide the best solution for each application we offer different measuring techniques and configurations/options. Overall, our expertise in these measurement systems and our ability to provide customized solutions ensures maximum resource efficiency for our customers in the beverage and food production industry.

Hydrostatic level measurement: In this technique, the fill level is measured by pressure transmitters at the bottom or top of the container and displayed and/or output to the PLC. For aseptic or pressurized tanks the level control with a Differential Pressure Sensor offers a suitable solution.

Potentiometric measurement: These sensors are mounted on the top, the side or the bottom of a tank, with a rod which extends into the liquid. They determine the fill level by changes in the voltage ratio in the measuring rod.

Weight measurement: The mass of the container and its contents is determined by using strain gauges or pressure cells which measure the change in pressure on the legs of the vessel/silo.

In addition to the application and the measurement technology itself, there are other parameters that must be considered when deciding on a system or product, such as:

- The hygienic design of the sensor and process connection

- The lifespan of the components

- Resistance to chemical or mechanical stress

- Basic measurement accuracy

- The impact of temperature drift

- Display requirement on site / via remote display / PLC data transmission only

- Data transmission (analog / digital)

- Simple operation, etc.

Due to the variety of different requirements, we offer diverse measurement techniques and configurations/options to ensure that you get the best solution for each application.

Download Our Whitepaper for a Comprehensive Guide

Our new whitepaper offers an in-depth look at level measurement technologies for hygienic food and beverage processes. It includes a comparison table showing the best measurement methods for specific applications, helping you make an informed decision for your process.

Find the Best Sensors for Your Process

Let Anderson-Negele guide you in selecting the most efficient level sensor for your specific application. Whether you need precise control for storage tanks, maturation vessels, or process containers, we offer solutions tailored to your industry needs.

Anderson-Negele Level Sensors

Reach Out for a Customized Solution

Copyright © 2022 Anderson-Negele