Product News

Available now: Flow meters for any application

22 Apr 2021

Additional info and FAQ about flow measurement:

How can flow meters and flow switches optimize processes, ensure product quality, and save costs?

Flowmeters can be used for the precise determination of the quantity or volume of media flowing into systems. They are the basis for safe and efficient processes in almost all applications in the food and beverage industry.

Typical examples are

How can a flowmeter save costs?

Measuring the quantity or volume with the highest accuracy can directly save costs due to loss prevention and better use of resources. Indirectly a cost reduction is achieved by recipe optimization and improved control of the blending process. The specified quantities of the valuable resources are precisely adhered to so that the final product can be produced in an optimal and reproducible way in precisely the desired quality.

What are the possible measuring methods for flow control?

Essentially, the Anderson-Negele product line offers two measuring principles for the flow measurement of liquids: electromagnetic flow measurement and turbine flow measurement.

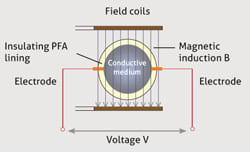

What is the electromagnetic flow measurement?

This measuring principle is based on Faraday’s law of induction. A constant magnetic field is generated by two field coils arranged vertically in the measuring body. The induced voltage is measured horizontally via two stainless steel electrodes. This voltage is generated, i.e., induced by the flow of conductive medium. It is directly proportional to the flow velocity and can be converted directly into flow volume. The outputs are available as a counting pulse, as a 4…20 mA standard signal and, in the case of IO-Link devices, digitally.

Which products are suitable for electromagnetic flow measurement?

Starting from a minimum conductivity of > 5 μS/cm, the induced voltage can be measured. This technique is suitable for media such as milk, cream, beer, ketchup, sauces, creams, mash, molasses, yogurt, concentrates, cleaning media, and many others.

What is turbine flow measurement?

This measuring principle works with a non-contact pulse measurement. A turbine sits directly in the liquid flow and is set in rotation by its rotor blades through the flow movement. A signal probe generates an electromagnetic field via an oscillating circuit. The rotating rotor interacts with this field to create an induction current, which can be precisely measured and output by the probe.

Which products are suitable for turbine flow measurement?

Turbine flow meters with non-contact pulse measurement are the reliable, precise, and economical alternative to mass flow meters or electromagnetic flow meters. This measurement technology is also suitable for non-conductive, aqueous media such as filtered fruit juice or beer, alcohols, light oils, salt solutions, cleaning media, and acids, but also process water, demineralized water, and WFI.

What is the Flex-Hybrid technology with IO-Link and 4…20mA parallel?

If you want to control the entire process plant technology with a large number of measuring, control, and operating devices, the digital interface IO-Link offers significant advantages over analog technology.

With its Flex-Hybrid technology, the FMQ flow meter combines the best of two worlds: data from the sensor can be transmitted in a digital, or analog way, or parallel in both technologies. This creates a significant advantage, especially in times of technological change from today’s analog to digital IOT generation: If, for example, you currently still control a system in analog mode, but consider a conversion to IO-Link, you no longer need to make a decision. Instead of “either … or”, Anderson-Negele uses the word “and”. Simply by connecting a new cable, the sensor can be switched to digital at any time later without even touching the hardware or the settings. Installation and commissioning are extremely time- and cost-effective. For the signal transmission and the power supply itself, a three-pole standard cable without shielding is sufficient.

Copyright © 2022 Anderson-Negele