Inductive Conductivity Measurement Sensors

Inductive conductivity measurement sensors deliver crucial data to optimize CIP (Clean-in-Place) processes, supporting:

- Precise concentration control of cleaning agents in supply tanks

- Continuous monitoring of solution strength throughout each cleaning phase

- Effective phase separation to recover and reuse chemicals, reducing waste

These sensors ensure efficient, cost-effective, and environmentally sustainable CIP operations.

Technologies Details

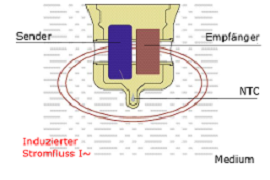

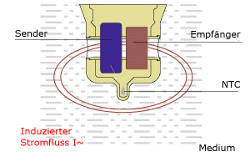

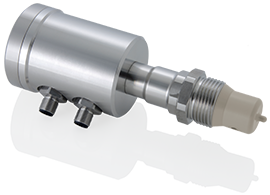

Inductive conductivity measurement works by generating an alternating current in the primary coil (transmitter), which creates a magnetic field that induces a current in the medium. This induced current produces a secondary magnetic field, generating voltage and current in the sensor’s secondary coil (receiver). The current measured in the secondary coil directly reflects the conductivity level of the medium.

Because liquid conductivity depends on the temperature, the sensor includes an integrated temperature sensor (NTC) in its tip to continuously record the medium’s temperature. This data allows electronics to compensate for temperature effects using a temperature coefficient (TK value), ensuring precise conductivity measurements.

The inline analysis of media based on their conductivity values enables automated, high-precision operation in many applications.

Here are examples of typical applications:

Product differentiation:

the distinction of liquids within one second ensures the correct processing, storage or filling of products, such as:

Phase separation:

the continuous media analysis enables real-time inline CIP stage control.

Process control:

by continuously measuring the conductivity value, a deviation of the actual value from the specified target value can be detected with very high accuracy and immediately signaled.

CIP media concentration control:

For an optimal and reproducible cleaning result, each cleaning agent must be adjusted to the specified value by re-dosing with concentrate and fresh water. This is ensured by the highly precise conductivity measurement with the ILM-4 in a separate process line.

In a variety of production processes and in CIP Systems, CIP skids in dairies, breweries, the beverage industry, wine production, juice production and other food companies, integrated conductivity probes can measure liquids according to qualitative criteria in-line, in real-time and fully automatically. Ideal applications are:

Copyright © 2022 Anderson-Negele