Reduce CIP Costs and Improve Overall Efficiency with LowCost, Easily Installed Turbidity Sensors

Dairy

Application Brochure:

Application Detail

Do you have a spare $10,000 to over $120,000 to waste this year?

If you’re still using sight glass, time control, or volume acquisition for the CIP process at your dairy, you’re losing money. Product waste is a reality in any dairy, but with the continually shrinking profit margins you face year-after-year, the need to reduce product waste is also a reality.

Costs Associated with CIP Usage

CIP usage has four main cost factors:

- Water

- Energy

- Time

- And, Chemicals

Saving $16,281.80 Every Year

To put this into perspective, an ice cream maker replaced a time-based system with turbidity sensors. Once the ITM-3(Now ITM-51) was fully integrated and running, the plant witnessed a thirty second difference between the old

timer based method and the new turbidity based method when they reviewed changeovers recorded on their PLC system.

Before they implemented the ITM-3(Now ITM-51) in their production process, correction batches were commonly done to deal with diluted production batches that brought their final mix out of spec (6 hours per week).

Today, they have tighter control of their process with the ITM-3A(Now ITM-51) and don’t have to do adjustment batches to correct for flush water getting into finished product and diluting their final mix.

During Clean in Place (CIP) the ITM‐3(Now ITM-51) is also used for pre-rinse to confirm that their piping system has been flushed clean. Prior to its use, this was done manually until an operator saw clear water; or by using a timer that was based on a piping configuration and flow rate that has more than likely

changed.

In addition to reducing their water usage by 19,500 to 39,000 gallons every year (at single flush point), they reduced their total loss per flush/changeover (fresh water, lost product, wastewater charges) by $639 per day.

Their net actual annual cost savings after payback of the system was $16,281.80.

How to Attain a Secure and Reliable CIP Process without Product Loss, Excess Waste or Risks of Contamination

“We had no idea that our old timer based method was wasting an average of $63.93 per day in profit or $16,621.80 annually after payback. “ --

Southeastern US Ice Cream Manufacturer

All devices that come into contact with milk based product must be thoroughly cleaned on a regular basis to eliminate bacterial contamination. CIP systems (Cleaning-In-Place) components that come into contact with the media, such as tanks and piping, must be cleaned without dismantling the system parts. This provides a viable level of availability for the production process.

As mentioned above, CIP has four main cost factors: Time, water, energy and chemicals.

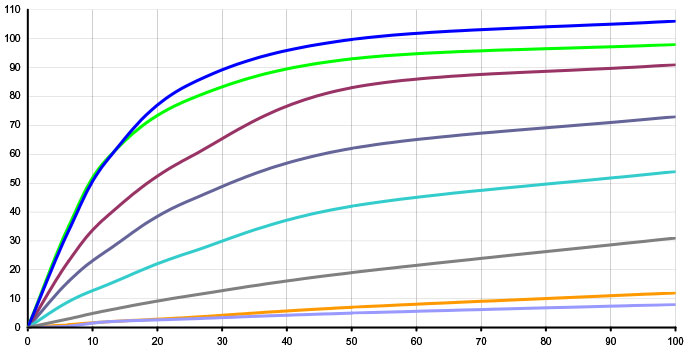

Time: The total time it takes to wash can be reduced by knowing exactly when the soil have been flushed from the system. Time-based methods can only approach a reasonable level of accuracy.

Water: TTS-Ciptec in Europe estimates that the average CIP cycle can consume between eight and 12 cubic feet of water. A highly accurate turbidity sensor can save upwards of 20% of the water usage.

Energy: Heating of the cleaning agents and water are the biggest energy consuming operations. The cost of heating chemicals is similar to the cost of water usage. By reducing the CIP cycle times, you can also reduce energy costs.

Chemicals: Costs of chemicals can vary considerably. Newer, additive chemicals are more expensive, but can reduce energy and water usage. After every wash is performed, some chemical is lost and mixes into the wastewater. Turbidity sensors can help reduce the overall cost by optimizing and reducing the CIP cycle times and monitoring the flow of solvents during the various stages.

The automation of the CIP process requires reliable turbidity sensors that can withstand harsh chemicals (acid and base) and frequent temperature fluctuations.

How It Works

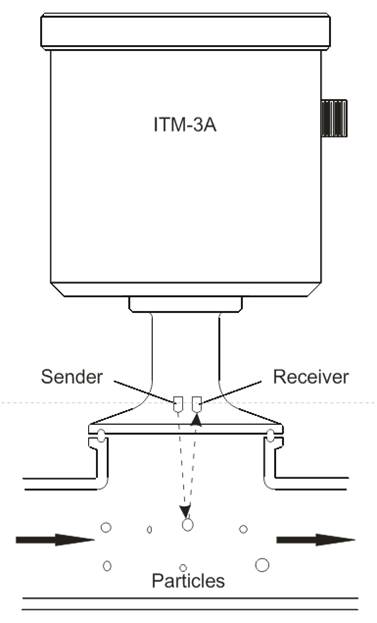

Turbidity is the phenomenon where by a specific portion of a light beam passing through a liquid medium is reflected by undissolved particles. The sensor measures the light that is reflected by these particles to determine their concentration in the liquid. Purified water would have close to zero undissolved particles, while ice cream mix has a high concentration of undissolved particles.

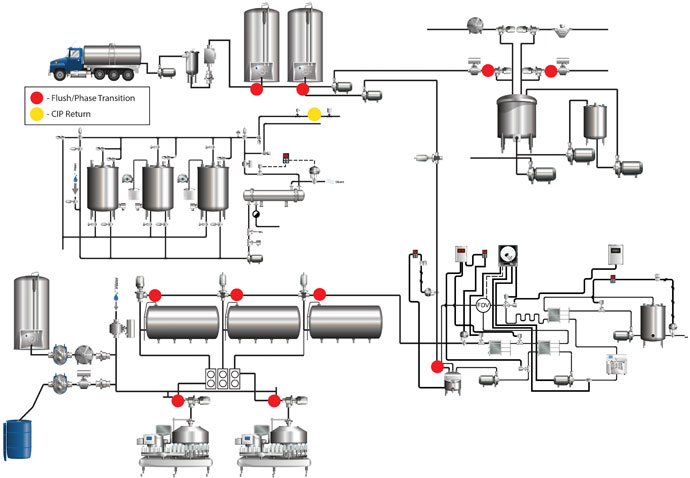

An inline turbidity sensor is installed at leverage points in the dairy product (see Fig. 1) handling process to facilitate instant detection of the following phase changes:

- Product-to-Product

- Product-to-Water

- Water to Cleaning Agent

- Pre-rinse with warm water

- Alkaline cleaning phase

- Intermediate rinse

- Acidic cleaning phase

- Disinfection

- Final rinse

- An Infra-red LED emits light into media through the sapphire lens

- The receiver measures the amount of light reflected back by particles suspended in the media

- It generates a signal that is proportional to the amount of particles. This is the relative turbidity

Advantages of Turbidity Sensors

Using the Anderson Instrument ITM-3, even minor changes to the dairy product can be detected and acted upon by the system – automatically and instantly. Your personnel and systems can be in total control and Instrument outputs automatically recorded for quality control records.

The stainless steel sensor resists corrosion, and the highly resistant sapphire glass optics provides incredible precision and a lifetime of five years or more (versus the required annual maintenance of quartz glass).

Overall, you’ll see:

- Improved product quality

- Quicker product changeovers

- Product waste reduction

- Reduced in sewage and water usage costs

- Lower BOD fees

- Less chemical use

- Enhanced process availability and reduced water consumption from cleaning efficiency

- Improved process control

- A return on your minimal investment in months or weeks

Installation and Reliability Considerations

Generally, the ITM-3 is easy to install because it is a fully-contained unit. It is extremely durable and rarely fails in the dairy environment. In the unlikely event of a failure you won’t have to wait long for a replacement sensor because the Anderson Instrument ITM-3 is always available.

Which Turbidity Sensor is Best?

There are dozens of turbidity sensors on the market. How do you compare apples to apples? Here are a few questions you can ask either your Anderson Instrument Regional Sales Manager or your dairy process control integrator:

- Cost: Cost is always a consideration, and “more” isn’t always better. That 240mph Porsche might be fun, but it’s not going to get you back and forth to work any faster than your trusty Ford pickup. Always consider what you need along with the cost.

- Reliability and maintenance: What kind of glass does it use, and what’s the lifetime cost of maintenance? Does it contain an extension on the lens to keep it clean and free of build-up?

- Ease of installation and use: Does it contain one or multiple pieces that have to be installed? What control systems, electrical connections, and mechanical connections does it require? Does it contain an operator interface and an easy way to reprogram it for different ranges?

- Output types: Does it contain a secondary output, such as a relay output in case you’d like to do simple automation without requiring a computer?

- Designed for Dairy: Has the product been adapted from other uses, or is it designed for the rigorous demands of the dairy industry?

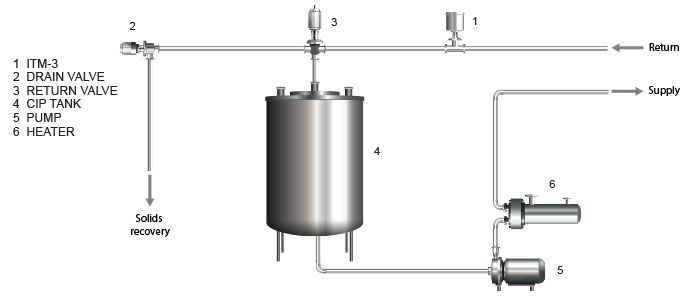

A Practical Application

The ITM-3 is located in the CIP return line before the drain valve. During the pre-rinse step of the CIP cycle the water returning from the cleaning loop is monitored by the ITM-3. The ITM-3 produces an analog output proportional to the relative turbidity of the returning rinse water. An automatic control (PLC) acts upon the input based on a setpoint that represents the optimal turbidity for the pre-rinse to be complete. Once the signal from the ITM matches the setpoint the control closes the drain valve and advances to the wash step of the cleaning cycle.

Find Out for Yourself

Speak today with your dairy process control integrator or your Anderson Instrument Regional Sales Manager to confirm that the Anderson Instrument ITM-3 is right for your situation.

You can be using the ITM-3 in as little as three to four weeks, quickly reduce your product loss, and begin seeing a return on your investment within a relatively short time.

The Anderson Instrument ITM-3 is the easiest turbidity sensor to install and implement. Using the Anderson Instrument ITM-3 is the fastest and most reliable way to reduce product waste and increase your profits without changes to your production process or product mix.

Key Advantages of the Anderson Instrument ITM-3

- Patented frontal sensor (EHEDG-compliant)

- Equipped with sapphire glass optics which are significantly more durable and abrasion –resistant than the competitor’s quartz glass approach

- No interference from reflections even when used with small nominal widths or electro-polished surfaces (i.e. nominal widths from DN25)

- Four measurement ranges can be elected in analog and switch output

- Illuminated onsite display

- Meets the CIP/SIP, etc. dairy industry process requirements

Copyright © 2022 Anderson-Negele