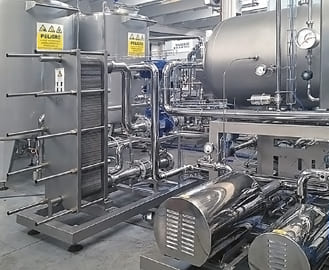

Level control in a carbonation plant

Food & Beverage

NSL: Precise hygienic level measurement even with high pressures, vacuum, foam, heat and boiling water

The systems manufacturer S.I.P.A. has earned a for quality and reliability in the field of beverage plants. In a soft drink plant

for a customer in Scandinavia, for reasons of cleanability and hygiene, a float level sensor was not accepted. On the advice

of an Anderson-Negele application specialist a test was carried out with the potentiometric level sensor NSL-M: And thanks

to its perfect function, it was not removed any more before the handover to the end customer. Since then, the system has

functioned smoothly for the end customer, and S.I.P.A. will use NSL technology for their systems in the future.

Customer

Michele Ravazzoni, S.I.P.A. Continuing Processing

We were looking for a new, hygienic solution that

would work in all processes, and especially also in

the CIP process because of the horizontal tank position.

Thanks to the competent advice from Smeri

and a product test with Anderson-Negele NSL, we

were able to more than meet all expectations. The

system works perfectly and smoothly for the end

customer. We are fully satisfied with the advice and

the product.

Advantages in the application

The customer benefits:

- Sanitary, easy to clean level measurement

- Reliable function and high measuring accuracy even under extreme positive pressure and vacuum

- Precise level measurement even during the CIP process, unaffected by spray water and boiling water

- Foam insensitive measurement

Application Detail

Degassing

The entire soft drink system consists of several components

that create great challenges for the measurement and control

technology. In the first part, the degassing tank, oxygen is removed

from the water to prevent taste deviations due to oxidation.

For this purpose, a vacuum is created in the tank and the

gas is extracted. For reliable processes, maximum efficiency

and consistent quality, highly precise volume measurement,

even under vacuum, is essential here.

Carbonation

After the mixing process of water and syrup according to different

recipes, in the next step, the liquid is enriched with CO2. This carbonation

takes place under high pressure up to the specified value.

The end product is stored in a stacking tank while maintaining

the pressure until filling. Here, too, the precise and above all fast

(less than 100 ms) measurement of the level is decisive for controlling

the process and to maintain a constant level.

The Anderson-Negele solution: The hygienic level sensor for extreme process conditions NSL

In the production process itself and in the CIP cleaning processes, the measuring instruments are exposed to extreme conditions. In particular, these are:

- High negative pressure (vacuum) during degassing

- High positive pressure (up to 95 PSI / 6.6 bar) during carbonation

- Strong foaming of the media (sparkling soft drinks)

- Fast temperature changes between process, CIP cleaning and rinsing

- Direct spray water on the probe during CIP cleaning, yet full function and measuring accuracy

- Dense steam that can negatively influence other measuring methods

S.I.P.A. has so far installed float sensors for level control in such systems. However, these no longer meet the current requirements for cleanability and hygiene. With the NSL-M,

S.I.P.A. has a solution which, thanks to a highly developed

potentiometric measuring system, has proven itself with its

high precision even under these rough conditions. This ensures

smooth operation with maximum product quality, process

reliability and efficiency.

Copyright © 2022 Anderson-Negele