Food, Beverage and Dairy

Life Sciences

Food, Beverage and Dairy Life Sciences

Food, Beverage and Dairy

Life Sciences

L3 Level and Pressure transmitter

Level Sensors, CIP Controls, IO-Link, Pressure Sensors

High precision hydrostatic level and control in vessels & process pressure measurement in pipes

Now available: L3 Neo with IO-Link in Flex-Hybrid Technology

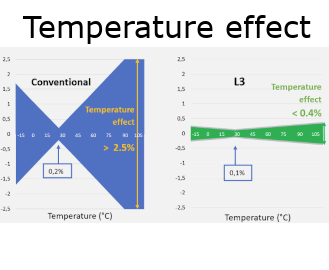

Neo, the next generation of the market-proven Level and Pressure Transmitter L3, sets new standards in Level and Pressure Control. With its exceptional performance characteristics, the L3 is particularly suitable for process pressure control in critical environments, or for superior level and volume measurement. This applies specifically for smaller vessels or for high and changing process temperatures for which pressure sensors were previously not considered precise enough.

- State-of-the-art temperature compensation reduces errors associated with process temperature changes

- Direct output of volume, level or pressure

- Integrated tank linearization and density compensation

- New electronics and robust design for toughest productions environments

- Flex-Hybrid Technology (IO-Link + 4…20 mA in parallel)

- Field repairable and reconfigurable design allows to change the display orientation, add a remote cable, or replace a component in the field without impact to accurac

- New Life Science version available

Technical Specification

| Process Connection | CLEANadapt | Milk tube | DRD | SMS Liner | Tri-Clamp | CPM | Endress & Hauser Universal |

| Insertion length | Stainless steel 1.4404 (316L) Ra≤0,8 μm |

| Wetted material | FOOD: Stainless steel 1.4404 (316L), Ra≤0,64 μm PHARMA: Stainless steel AISI 316L, Ra ≤ 0.2 μm (8 μin) |

| Measuring range | -1…35 bar Relative |

| Accuracy | ≤ 0.10% of the calibrated range |

| Available versions | Compact | Remote |

| Temperature range process | -18…110 °C |

| Temperature range CIP/SIP | 135 °C / max. 60 min. |

| Communication | 4…20 mA | IO-Link | HART |

| Technical Support: How to videos | Click here to view the playlist of our How to videos |

| The values shown are the performance limits within the product line. The product-specific data for each individual configuration can be obtained from the product information | |

Application

Videos

L3 Advantages and Applications

Wet calibration

Change units

Tank configuration

Re-Zero

Measurement range

Product density configuration

Factory reset

Alarm / switch output

Damping change

Range setting

Download

Process Connection

.png)

Copyright © 2022 Anderson-Negele