Food, Beverage and Dairy

Food, Beverage and Dairy

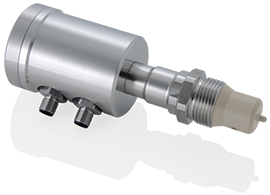

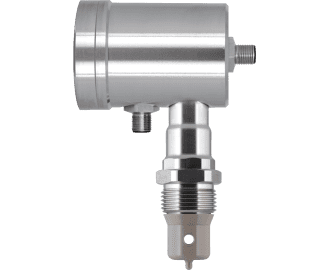

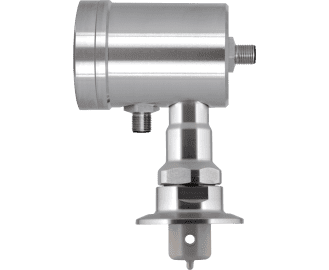

ILM-4 Conductivity Meter

Conductivity Sensors, CIP Controls, IO-Link, Process Analytics

Hygienic Inductive Conductivity Meter for liquid media up to 999 mS/cm, with IO-Link

Our quality promise: Extended Warranty 5 years

- Extremely short response time of 1.2s for highest efficiency

- Flex-Hybrid Technology: Digital IO-Link and analog 4…20 mA in parallel

- Accurate phase separation of different media means less resource losses and cost optimization

- Maximum use of the cleaning agents in CIP processes thanks to correct re-guidance into the respective storage tanks

- Minimum cleaning time and water consumption: active switch-over after reaching the desired value by inline analysis and not by passive, pre-set time control

- Precise concentration of the cleaning agents

- Modular design: configurable from the low-cost basic version to the high-end model

- Add-On Instructions (AOI) are available at www.anderson-negele.com/aoi

Technical Specification

| Process Connection | CLEANadapt G1" / Tri-Clamp / Varivent |

| Insertion length | 20 / 50 mm |

| Wetted material | Stainless steel, 1.4305, SW 36 mm |

| Wetted material 2 | PEEK (FDA conform) |

| Measuring range | 0...1000 mS/cm |

| Accuracy | Slope ±1 % of measurement value | Offset ±20 μS/cm |

| Available versions | Compact | Remote | Horizontal head | Vertical head |

| Temperature range process | -10…130 °C |

| Temperature range CIP/SIP | 150 °C / max. 60 Min. |

| Operating pressure | max. 16 bar |

| Communication | 4…20 mA, IO-Link |

| Dimensions / weight | ø 63 mm, approx. 750 gr. |

| Benefits | Benefits in production and CIP / SIP processes:

Benefits in cleaning agents control:

Advantages of the ILM-4 conductivity sensor: |

| The values shown are the performance limits within the product line. The product-specific data for each individual configuration can be obtained from the product information | |

Application

Videos

ILM 4 conductivity meter machined toroid design

PEEK toroid of the ILM-4 conductivity meter doesn’t crack

Demo of the operational screen selection on the ILM-4 conductivity meter

Instructions on how to change the operating range of an ILM-4 conductivity meter

How to change the temperature units on an ILM-4 conductivity meter

How to program the Temperature Compensation parameter of an ILM-4 conductivity meter

How to password protect the programming of an ILM-4 conductivity meter

.png)

Copyright © 2022 Anderson-Negele