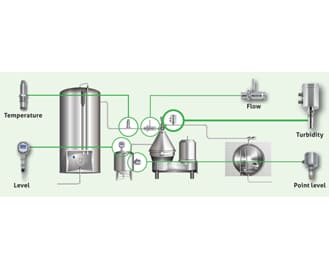

Butter-oil separation with turbidity measurement

Dairy

In production, processing and packaging of butter, the processing equipment is regularly cleaned and remaining butter residues are washed out with pre-tempered water to ensure reliable hygienic production.

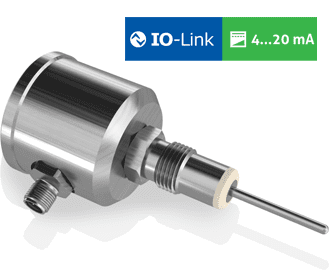

From this mixture, high-purity butter oil can be separated as a valuable raw material. An important instrument for its automated, economical and high-quality refinement is the ITM-51 turbidity sensor with a measuring range perfectly adapted to this application. In addition, sensors for flow rate, point level and temperature that match perfectly the specific medium support process control for maximum system efficiency and reliability.

Application Detail

The application

The water-butter oil mixture from the plant rinsing process is pumped into a stacking tank in which natural phase separation already takes place. In a separator the butter oil phase should then be concentrated to a refinement degree of 99.5%. However, visual control during phase separation did not allow sufficient accuracy for the final product. Continuous sampling offered better quality, but this required a lot of manpower and proved to be very cost-intensive.

Finally, automated phase separation based on high-precision turbidity measurement of the butter oil mixture with the ITM-51 turbidity sensor proved to be the most efficient method for ensuring consistently high and verifiable production quality in practical operation.

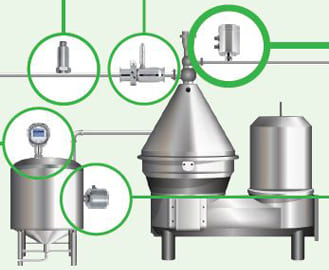

The Anderson-Negele solution

The ITM-51 turbidity sensor uses the backscattered light method, which detects the reflection of particles in the medium. With only one sensor head, it can be integrated very easily and front-flush into the pipe system using a weld-on socket or adapter.

For precise separator control, the ITM-51 was programmed individually in the application itself. For this purpose, samples were taken in a test run, analyzed in the laboratory and compared with the values displayed in the sensor. In the exemplary practical case, a range of 0-50 % TU was preset for a target maximum value of 0.5 % water content in the butter oil mixture.

The high process reliability in the separation of the phases ensures, on the one hand, a constant quality of the butter oil. On the other hand, the waste water management is considerably simplified, since the residual water is only contaminated to the minimum.

Further Anderson-Negele instruments

Flow

The reliable operation of the separator is monitored by one flow meter each in the separator inlet and separator outlet. Due to the low conductivity of the butter oil mixture, magnetic- inductive flow meters cannot be used here. The HM-E turbine flow meter is ideal for this application. Independent of the conductivity of the media, it achieves a very high measuring accuracy of ±0.5 % due to a rotor with non-contact pulse measurement.

Level / Point level

At certain intervals, the residual mass from the separator has to be emptied into a discharge drum. The fill level of this container must be monitored for automated control of the entire process. For this purpose, either a continuous level measurement with the potentiometric NSL-F is possible, which ensures fast and very precise level monitoring even with the pasty, creamy mass. Alternatively, an NCS point level detector can be used, which is likewise independent of the conductivity of the medium and indicates with a full signal that emptying of the discharge container is required.

Temperature

Process monitoring based on temperature is made possible by a large number of different sensor types. In this application, the flush TFP version is ideal, as no components protrude into the tube and the product flow remains completely unobstructed and can be cleaned by pigs.

.png)

.png)

.png)

Copyright © 2022 Anderson-Negele