Application Detail

Is the Anderson Instrument ITM-51 Turbidity Sensor Right for Your Dairy?

This document will help you to understand how the ITM-51 Relative Turbidity Monitor (and the ITM-4) can fit into your dairy operations.

By switching from time based or other older technologies, you can significantly reduce product loss, reduce wastewater costs, improve the efficiency of your operations, and (with the ITM-4) certify your recovery processes.

This report is divided into three sections:

- Will you benefit from turbidity sensors?

- Is the ITM-51 a good option for your dairy?

- About the ITM-51 relative turbidity monitor

Will you benefit from Turbidity Sensors?

- Are you using sight or time control to manage phase transitions and CIP in your process today?

- Are you using conductivity to manage your dairy waste water diversion today?

If you answered YES to either of the above questions, then you can benefit by switching to turbidity sensors.

Is the ITM-51 a good option for your dairy?

The following questions will help you to determine if the ITM-51 fits your needs and budget.

| YES | NO | Don't Know | |

| Would you prefer that your turbidity sensor supplier have deep experience with dairy operations? | |||

| Would you like to have a fast payback of your investment to help justify the cost, time and hassle of switching? | |||

| Is low cost a priority? | |||

| Are you concerned about ongoing maintenance costs and hassles? | |||

| Would you like to have an on-unit operator interface to monitor the sensor and ensure that it’s working properly? | |||

| Would you like to have both an analog and relay output for simple automation without involving a computer? (As opposed to just analog) | |||

| Would you prefer to only pay for the features/performance you need instead of paying extra for features you don’t need? | |||

| Is ease of installation and ease of use important? | |||

| Would you prefer a long-lived light source for the sensor (3-8 years) over a light source with a 1-year lifetime? | |||

| Do you think that it is important to have a sensor that stays clean? That is, the frontal sensor is EHEDG compliant and its performance is not impacted by media buildup. | |||

| Is it important to you that the glass optics have an extremely high reliability rating? (Sapphire versus much more fragile quartz) | |||

| Would you like a sensor that can tolerate interference from reflections even when used with small nominal widths or electro-polished surfaces (i.e, nominal widths from DN25)? | |||

| Would you like to have a full 4 to 5 ranges for your analog and switch output? | |||

| Is switching output (switch point and hysteresis free adjustable) important to you? | |||

| Is it important for your turbidity sensor to meet the CIP/SIP, etc. dairy industry process requirements? | |||

| Would you prefer that your turbidity sensor be color independent (wave length 860 nm)? | |||

| Do you need the ability for your turbidity sensor to use DN25 pipe? | |||

| Would you like to have a turbidity sensor that has close to 1% full scale reproducibility? |

About the ITM-51 Relative Turbidity Monitor

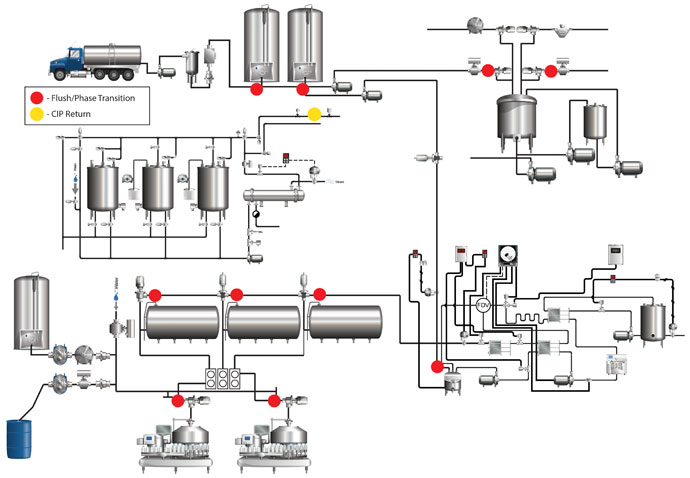

The ITM-51 can be used in a variety of locations in your dairy as indicated in the above diagram. Below are more detailed explanations of some of the major uses of the ITM-51 turbidity sensor. General Description of the ITM-51

Principles of Operation

- An Infra-red LED emits light into media through the sapphire lens

- The receiver measures the amount of light reflected back by particles suspended in the media

- It generates a signal that is proportional to the amount of particles. This is the relative turbidity

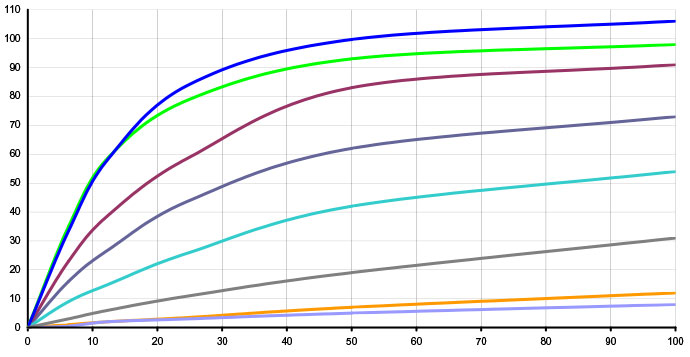

Turbidity Readings of Typical Products

Key Specifications

(Click Here to see the complete ITM-51 specifications document)

- Measuring range starts at 2000 NTU

- Display for indication and programming

- 4-20mA output assignable to 5 ranges (10,20,50,100,200)

- DC Switched output adjustable 0- 200

- Adjustable dampening 0,1,3,6,13, and 25sec

- One unit with transmitting beam, and receiver-no need for any other parts

- 2 M12 connectors(1 needed for power with analog output)

- 3-A TPV

Phase Transition

Phase transition is the most common application of the ITM-51 and is where you will generally find your quickest payback.

The PLC is programmed based on the known turbidity values for acceptable products. The sensor feeds the measurement signals to the PLC (or controller) with a 4-20mA signal. The PLC or controller provides an instantaneous decision to control phase changes based on turbidity instead of sight or time.

Thus, changeovers are not subject to changes in piping configuration or water pressure.

CIP Rinse Water Recovery (Pre-Rinse Control)

Application:

- A turbidity sensor is located on the return line of a CIP cleaning loop prior to the return drain valve.

- Sensor feeds measurement signals to the controlling PLC

- PLC provides decision based on the ITM-51 measurement of the rinse water to determine that the rinse is clear of soil allowing the system to advance to the next step

At the beginning of a CIP cycle, water pre-rinse is initiated to flush the residual product from the process equipment loop that is being cleaned. A turbidity sensor gives an indication when the rinse water has flushed a sufficient amount of soil from the loop. Value to Your Dairy:

- More effective rinses over time-based systems

- Flexible to multiple cleaning loops

- Optimizes water/rinse use by using just enough

- Reduction of cleaning chemical use

- CIP cycle time reduced to minimum

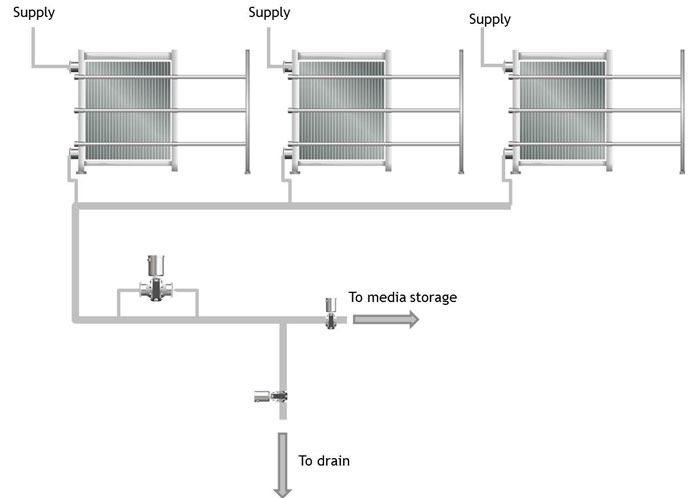

Chill Media Monitoring

Application:

- Turbidity sensor is installed on the return line for chill media to measure turbidity

- Sensor feeds measurement signals to PLC or directly controls drain valve with internal switching

- PLC provides decision based on comparison of incoming value versus establish limit and diverts media flow to drain

Value to Your Dairy:

- Gives early detection of heat exchanger failure

- Saves media tank and piping from dairy contamination

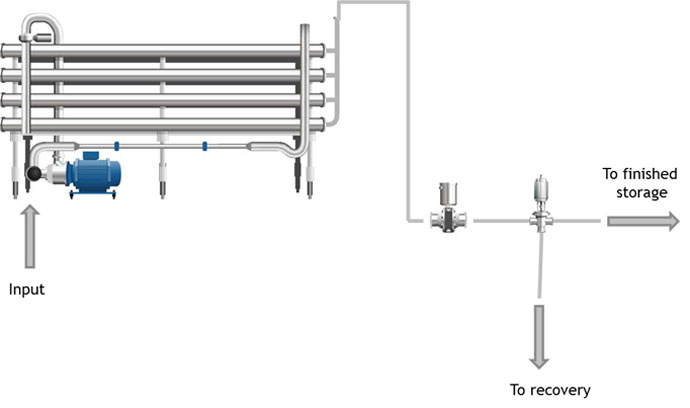

Filter Monitoring

Application:

- ITM-51 (or an ITM-4) turbidity sensor is installed on the pipeline downstream of the filter to measure product turbidity

- Sensor feeds measurement signals to PLC or controller 4-20mA signal

- PLC provides decision based on a comparison of incoming value versus known value for acceptable products. When the threshold is exceeded alarm state is reached and system is shut down.

Value to Your Dairy:

- Early detection of filter failure

- Can provide immediate shut down saving product

Note: ITM-51 for higher turbidity – will identify any major failures. ITM-4 for lower turbidity – can give indication of early failure on critical applications

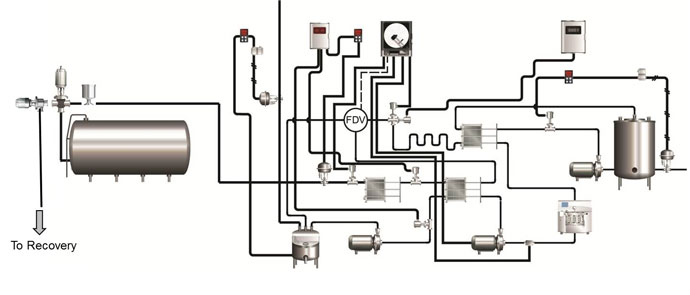

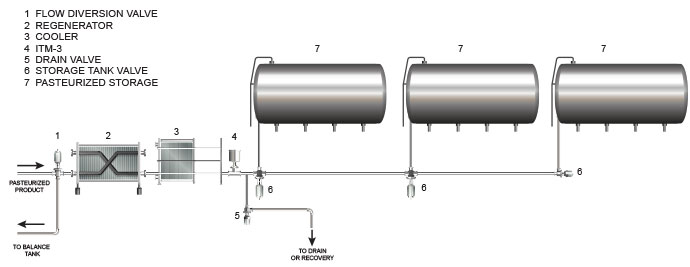

HTST Water Flush Transition Detection

Application: A turbidity sensor is located on the discharge piping prior to the final pasteurized storage tanks.

Following a production run a pasteurization piping schematic is chased with water to recover pasteurized product to the storage tanks. A turbidity monitor gives indication that the product-water interface has finished moving through the piping schematic.

The ITM-51 is located at the discharge of an HTST processing system to continuously monitor the relative turbidity of liquid in the pipeline. When a product process run is completed a water flush is initiated on the input side of the system to push the product from the system into the pasteurized storage tanks. The ITM-51 continuously monitors the solids content of the outgoing liquid and gives an analog output signal of the relative turbidity. As the turbidity begins to decline caused by dilution with water a decision is automatically made by the control system to redirect flow from the storage tanks to drain or the waste water recovery system.

Value to Your Dairy:

- Fast acting electronics offer quick response to product changes, enabling predictable recovery

- LED lamp technology avoids deterioration in measurement experienced by other illumination sources

- Standard programmable switched and analog outputs simplify integration into plant control systems

- Extended “L” model overcomes the difficulties of measuring transition with high viscosity product applications

- Selectable ranges increase resolution to achieve optimal trigger points for flow diversion.

Get a Quote and Configuration

Contact Anderson-Negele today if you’d like to learn more about the ITM-51 turbidity sensor.

Copyright © 2022 Anderson-Negele