Temperature and limit measurement points for the pharmaceutical industry. Negele Messtechnik GmbH has made a name for itself in the food industry as an innovative manufacturer

Life Sciences

Application Detail

Negele Messtechnik GmbH has made a name for itself in the food industry as an innovative manufacturer of sensors and process integration systems. In addition, Negele is increasingly establishing itself as an expert in tailored solutions for the pharmaceutical and biotech industries.

In the pharmaceutical industry, a consistently high product quality is critical to the survival of any manufacturer. Apart from reliable and reproducible process monitoring, this requires components that can be cleaned and sterilized with absolutely no residue. The systems and sensors used in production must be designed to reflect this requirement. Negele Messtechnik has brought out two build-in systems for the pharmaceutical industry that it developed specifically to meet these demands.

Aseptic temperature measurement without opening the process pipelines – highly precise and fast

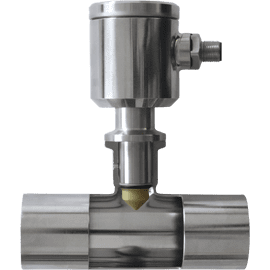

Many systems in the pharmaceutical industry exhibit very small nominal diameters. With PHARMadapt ESP, Negele off ers precisely sized measurement points with nominal diameters from DN 9 for pipe elbows and DN 10 for straight pipe. The exactly defined submersion depth of these sensors ensures measurement precision in both installation situations. Highly accurate Temperature measurement, rapid response times and the lack of need to open process pipelines are the main advantages of this system, giving it a significant edge over the commonly used pipe-mounted sensors.

With a design that is devoid of dead leg, the ESP measurement points are easy to clean. In addition, cleaning is supported by the high fl ow speeds in the CIP process that cause the measurement tip to be actively flushed. The hygienic construction has been awarded certification according to the 3-A 74-06 Sanitary Standard.

Many systems in the pharmaceutical industry exhibit very small nominal diameters. With PHARMadapt ESP, Negele off ers precisely sized measurement points with nominal diameters from DN 9 for pipe elbows and DN 10 for straight pipe. The exactly defined submersion depth of these sensors ensures measurement precision in both installation situations. Highly accurate Temperature measurement, rapid response times and the lack of need to open process pipelines are the main advantages of this system, giving it a significant edge over the commonly used pipe-mounted sensors.

With a design that is devoid of dead leg, the ESP measurement points are easy to clean. In addition, cleaning is supported by the high fl ow speeds in the CIP process that cause the measurement tip to be actively flushed. The hygienic construction has been awarded certification according to the 3-A 74-06 Sanitary Standard.

The prefabricated build-in pipes can be quickly integrated in the production pipelines in a clean and cost-eff ective manner by means of orbital welding. In addition to all nominal diameters up to DN 100 as per the DIN, ISO and ASME pipe standards, the units are also available in different surface qualities (electropolished). All standard certificates in this sector can be provided (including inspection certificate 3.1, surface roughness, and delta ferrite content). The temperature sensor comes in a variety of models that are compatible with the build-in system.

These include a standard sensor head for different head transmitters and a miniature version for cramped installation conditions. A major advantage of the ESP system is the ability to remove the sensor for calibration without opening the process pipelines or detaching the electrical connection. As a result, system maintenance is quick and cost-effective. Another benefit is reliability, since lines cannot be accidentally opened during procedures such as steam sterilization.

The prefabricated build-in pipes can be quickly integrated in the production pipelines in a clean and cost-eff ective manner by means of orbital welding. In addition to all nominal diameters up to DN 100 as per the DIN, ISO and ASME pipe standards, the units are also available in different surface qualities (electropolished). All standard certificates in this sector can be provided (including inspection certificate 3.1, surface roughness, and delta ferrite content). The temperature sensor comes in a variety of models that are compatible with the build-in system.

These include a standard sensor head for different head transmitters and a miniature version for cramped installation conditions. A major advantage of the ESP system is the ability to remove the sensor for calibration without opening the process pipelines or detaching the electrical connection. As a result, system maintenance is quick and cost-effective. Another benefit is reliability, since lines cannot be accidentally opened during procedures such as steam sterilization.

Temperature and level measurement points for the pharmaceutical industry

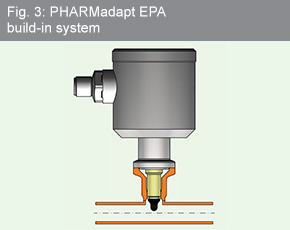

A further build-in system for pharmaceutical applications is the PHARMadapt EPA product series.

In developing the EPA system, the special requirements and standards of the pharmaceutical industry were taken into account, resulting in a very compact measurement point with an elastomer seal, optimal hygienic design and rapid sensor installation.

With EPA-8, the user can now not only measure temperatures, but can also record the level in pipes with a nominal diameter of DN 8 and larger. For pipes with diameters larger than DN 25, the EPA-18 installation system is available as a variant with the necessary geometry.

The weld-in pipe and sensor are constructed in such a way that the sensor tip always reduces the cross-sectional area of the pipe by a fixed amount. In addition, the configuration is free of dead leg and gaps. The measurement point design was developed in view of the EHEDG guidelines, and the hygienic design of the installation flanges and sensors is certified according to the 3-A 74-06 Sanitary Standard.

Like the ESP build-in system described above, the PHARMadapt EPA offers the advantage of prefabricated build-in pipes, enabling the unit to be installed rapidly and cost-effectively by means of orbital welding. Here, too, the DIN, ISO und ASME pipe standards are available with the various surface qualities and certifications.

A further build-in system for pharmaceutical applications is the PHARMadapt EPA product series.

In developing the EPA system, the special requirements and standards of the pharmaceutical industry were taken into account, resulting in a very compact measurement point with an elastomer seal, optimal hygienic design and rapid sensor installation.

With EPA-8, the user can now not only measure temperatures, but can also record the level in pipes with a nominal diameter of DN 8 and larger. For pipes with diameters larger than DN 25, the EPA-18 installation system is available as a variant with the necessary geometry.

The weld-in pipe and sensor are constructed in such a way that the sensor tip always reduces the cross-sectional area of the pipe by a fixed amount. In addition, the configuration is free of dead leg and gaps. The measurement point design was developed in view of the EHEDG guidelines, and the hygienic design of the installation flanges and sensors is certified according to the 3-A 74-06 Sanitary Standard.

Like the ESP build-in system described above, the PHARMadapt EPA offers the advantage of prefabricated build-in pipes, enabling the unit to be installed rapidly and cost-effectively by means of orbital welding. Here, too, the DIN, ISO und ASME pipe standards are available with the various surface qualities and certifications.

Temperature measurement with PHARMadapt EPA

Level detection with PHARMadapt

Copyright © 2022 Anderson-Negele