Fruit slurry for the perfect smoothie

Food & Beverage

Peak Foods is a joint venture between Interstate Food Processing Corporation and Lakeside Foods. They are specialized in whipped topping products for the retail, foodservice and industrial sectors.

For a new business line, ingredients for smoothies of its own brand Blendtopia, Peak Foods utilized some experience from dairy production, but also had to implement new innovative processes. In High Temperature Short Time (HTST) Pasteurization, the highly viscous consistency of fruit purees presented a particular challenge. With the FMI flowmeter, the process now can be controlled with the highest precision.

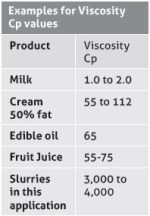

For its new Blendtopia brand, Peak Foods develops and produces ingredient concentrates that allow end customers to easily and quickly prepare themselves healthy smoothies. These concentrates are primarily fruit slurries, such as banana or strawberry purees, and are characterized by a very low water content but a high percentage of fruit chunk. The special production process, developed for perfect product consistency, results in high demands on the manufacturing equipment. The very high viscosity of up to about 4000 Cp, the very low flow rate of about 5.7 l/min and the low production temperature of 5 – 8 °C were a challenge especially for the flow measurement. However, for evidence of pasteurization, flow control needs to be highly accurate and reliable.

Customer

Rich Griffin, Engineering Manager

These tests were a pure success story. We were able to prove that the measurement accuracy fully met expectations. In addition, the FMI is significantly more cost-effective than a comparable Coriolis Meter, so that we can now use the best technical solution at the most favorable price.

Advantages in the application

- High-precision flow measurement even at very low flow velocity and highly viscous consistency

- Less product loss during phase transition due to turbidity monitoring with the ITM-51

- Help with sensor selection, configuration and design by the Anderson-Negele Support team

Application Detail

Magnetic-inductive flow measurement with highest precision

Prior to the startup of the new facility, high pressure pasteurization was performed by a third-party vendor. According to Rich Griffin, engineering manager at Peak Foods, "this process was tedious, caused time delays and increased costs."

However, to bring production in-house, the experience gained from dairy production was not enough, new processes had to be tested and fine-tuned. After initially considering a Coriolis mass flowmeter to monitor the HTST pasteurization system, distribution partner OCS Process Systems helped to review specifications and clarified best practice solutions with the Anderson-Negele Technical Support team. OCS recommended the FMI electromagnetic flowmeter. With the small pipe diameters in the facility, this technology promised higher measurement accuracy on paper. Therefore, during commissioning, extensive tests were run with the most extreme requirement, i.e. the thickest fruit puree.

"These tests were a pure success story. We were able to prove that the measurement accuracy fully met expectations. In addition, an IZMAG is significantly more cost-effective than a comparable Coriolis Meter, so that we can now use the best technical solution at the most favorable price" concludes Rich Griffin.

Significant cost savings thanks to resource control through turbidity measurement

In CIP systems, time control is often used for phase transition. To be sure that a media has been completely pushed out, buffer times are embedded into the control system. Peak Foods uses an ITM-51 turbidimeter, which measures the change of media in real time and enables valve control without loss of production time.

"Compared to classic phase separation, we can regain large amounts of our valuable product and save costs" explains Rich Griffin. An experience that numerous users can confirm: In many applications, an ITM turbidimeter pays for itself within a few weeks only.

.png)

Copyright © 2022 Anderson-Negele