No more flooding, Reliable hydrostatic level measurement without sensor drift in any climate conditions!

Brewery, Dairy, Food & Beverage, Life Sciences

Application Detail

Filling level measurements with hydrostatic pressure transmitters are widely used, similarly widespread with these sensors are, unfortunately, drift phenomena and unstable measurements. These problems become evident by the fact that after a certain period in operation the measured values are no longer credible. In principle the phenomenon occurs on all hydrostatic filling level sensors, independent of manufacturer. Here the reasons for this behaviour are investigated, and a solution is put forward.

Reason for sensor failures - problems associated with hydrostatic filling level associated with hydrostatic filling level sensors

- a pressure measurement cell with a compensation capillary to compensate for atmospheric pressure, and

- a double membrane, in this case fitted, however, with a Gore-Tex filter as a moisture barrier.

How does the condensate form (saturated water vapour)

Negele sets a new standard - previous problems are now a thing of the past problems are now a thing of the past

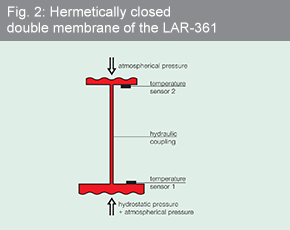

With the LAR-361 hydrostatic filling level sensor, newly introduced into the market, the actual internal measurement system is hermetically welded up such that any penetration of gases is completely impossible.

However even in this relative pressure measurement cell compensation for air pressure still takes place. This is made possible by means of a simple trick: the air pressure is exerted upon a second measurement cell. The latter directs the air pressure via a small tube filled with oil on to the rear face of the process pressure measurement cell. As already described above, the measurement signal is provided solely by the hydrostatic pressure that is of interest. The special feature here is that the air pressure cell and the process pressure cell are hermetically sealed and hydraulically connected. This comprehensively excludes the entry of moisture into this sensitive region. The problem is therefore attacked not in its effect, but at its cause. FDA-listed mineral oil serves as the hydraulic coupling medium.To carry out the temperature compensation that is also required, appropriate sensors are fitted to the measurement cells. The sensor can therefore be operated under all moist and wet installation conditions, both internally and externally, for which conventional sensors have only a very limited service life.

With the LAR-361 hydrostatic filling level sensor, newly introduced into the market, the actual internal measurement system is hermetically welded up such that any penetration of gases is completely impossible.

However even in this relative pressure measurement cell compensation for air pressure still takes place. This is made possible by means of a simple trick: the air pressure is exerted upon a second measurement cell. The latter directs the air pressure via a small tube filled with oil on to the rear face of the process pressure measurement cell. As already described above, the measurement signal is provided solely by the hydrostatic pressure that is of interest. The special feature here is that the air pressure cell and the process pressure cell are hermetically sealed and hydraulically connected. This comprehensively excludes the entry of moisture into this sensitive region. The problem is therefore attacked not in its effect, but at its cause. FDA-listed mineral oil serves as the hydraulic coupling medium.To carry out the temperature compensation that is also required, appropriate sensors are fitted to the measurement cells. The sensor can therefore be operated under all moist and wet installation conditions, both internally and externally, for which conventional sensors have only a very limited service life.

Typical areas of application and operation

Further areas of application

Further advantages offered by Negele’s LAR-361

- metal membrane with Ra < 0,4 µm in contact with the product fulfils the highest aseptic demands.

- IP 69K protection, and thus protected against water during highpressure and steam jet cleaning

- can be variably adapted to each process by means of an extensive range of process connection designs

Copyright © 2022 Anderson-Negele