Client Logo

Bürgerliches Brauhaus Saalfeld D-07318 Saalfeld/Saale

Bürgerliches Brauhaus Saalfeld D-07318 Saalfeld/Saale

Application Detail

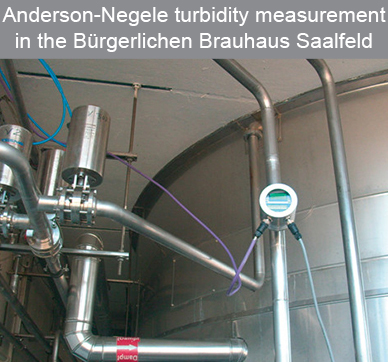

Brauhaus Saalfeld uses Anderson-Negele turbidity measurers to monitor turbidity in the lauter tun.

The first and decisive step in purifying the wort takes place during lautering in the brewhouse. Too high solid concentrations, which can be caused by excessive husk ratios for example, can lead to fermentation problems and therefore to a reduction in the beer quality.

The inline turbidity measure has now become a widely used and recognised process for the automated monitoring of the solids concentration. However, in many places this process is still controlled by time and quantity, or even by visual inspection using an inspection glass. The Bürgerliche Brauhaus Saalfeld successfully uses the Anderson-Negele turbidity meter for control and monitoring during the purifying process.

The process

Anderson-Negele turbidity measurement in the Bürgerlichen Brauhaus Saalfeld

The appropriate process for every requirement

ITM-4: Scatter method for lowest turbidity

If the turbidity of the wort to be measured is very low based on production, or if the process has to be controlled differentiated. For these applications the four-beam turbidity meter ITM-4 is recommended by Anderson-Negele. The meter operates according to the 90° scatter method, whereby the turbidity values in the range of 0...1250 EBC are measured. The reading is emitted as a 4...20 mA signal according to the preselected measuring range and, in addition, any threshold value can be analysed using the digital signal. ITM-4

ITM-51: The economic solution for medium and high turbidity

If the recognition of higher turbidity, as frequently occurs in the event of a breakthrough of the filter cake, is sufficient for the control of the purifying process then the Anderson-Negele turbidity meter ITM-51 can be used as an alternative. The meter operates according to the so-called backscatter principle and is suitable for turbidities over about 500 EBC. Regarding the functional scope, no compromises have to be made with the ITM-51 with respect to its “big brother” ITM-4. Display, analogue output and a freely adjustable switch output are also included here as standard. The metallic sealing G1/2" CLEANadapt process adaptation also provides an absolute front flush mounting, easy to clean build-in situation. No separate flow valve is required for the connection to the process. This usually takes place over an economical weld-in sleeve or over a suitable adapter for valves that are already present. ITM-51

NEGELE turbidity meter: proven and reliable

Anderson-Negele turbidity meters are proven and reliable and are used for the continuous monitoring and control of many processes in drink production. The wear-free LED technology and the materials used (sapphire glass optics) make Anderson-Negele turbidity meters both maintenance friendly as well as impervious to drift and build-up and guarantee reliable operation, even after many CIP/SIP cycles. Expensive lamp replacements that are popular in other procedures now belong to the past. The typically straightforward Anderson-Negele service, the few necessary parameters and the compact execution define the ITM-51 and ITM-4 meters with high practical use and guarantee fast start-up and simple maintenance.

.png)

Copyright © 2022 Anderson-Negele