Severe climates with high humidity and cold temperatures. Reliable level measurement in dairies

Dairy

Application Detail

Hydrostatic level measurement using a pressure sensor is a standard procedure in many dairy applications. Nevertheless, problems with drift or unstable measurements are not uncommon. These usually occur in areas prone to condensation, such as storage tanks, where cold media are measured in a humid environment. Because condensation can potentially lead to the complete failure of the measurement sensor, many users look for the cause of the problem and a technical solution.

Analyses have shown that these failures are often due to how the measuring principle is applied. In hydrostatic

level measurement, a pressure sensor located at the lowest point in the tank measures both the pressure of the fluid column above it and air pressure. To obtain the correct level, the measurement result must compensate for the air pressure. Otherwise, air pressure fluctuations, which usually range up to approx. 50 mbar, would lead to measurement result variations of up to 16% in a tank filled three meters high. To avoid this inaccuracy, the air pressure must be compensated for in the result.

Methods of avoiding measurement errors

Two different models of climate-resistant sensors are available on the market that avoid this type of measurement error:

Two different models of climate-resistant sensors are available on the market that avoid this type of measurement error:

- Pressure measuring cells with equalizing capillaries that compensate the atmospheric pressure

- Sensors with a permeable double membrane as a humidity barrier

Alternative state-of-the-art methods

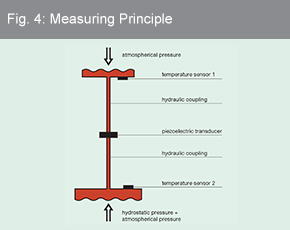

The sophisticated LAR-361 (Fig. 3) hydrostatic level sensor from Negele Messtechnik GmbH, which has been on the market for a number of years, differs from other measuring equipment in that the measuring system itself is hermetically sealed. This prevents gases and humidity from entering the system. In addition, the relative pressure measuring cell is still capable of providing readings in which the air pressure has been compensated for. The main difference to systems with permeable membranes is that in this unit, the atmospheric pressure is measured by a second measuring cell integrated in the sensor. This cell is hydraulically connected with the membrane of the process pressure measuring cell, which is in contact with the medium being measured (e.g., milk). The measuring cell for the atmospheric pressure (= pressure measuring cell for the ambient air pressure) conducts the measured pressure onto the rear of the process pressure measuring cell via an oil-filled tube. With the atmospheric pressure compensated for in this way, the reading is a measure of the hydrostatic pressure only, which in turn can be used to establish the filling level of the container. A further special feature is that both the process pressure measuring cell and the air pressure cell are hermetically sealed and hydraulically coupled (Fig. 4).

This design prevents the penetration of humidity into this sensitive area. Thus, the approach of this method is to solve the root of the problem rather than to correct the effects. The coupling medium consists of an FDA-approved oil filling. In addition, the pressure sensor is equipped with temperature sensors attached to the measuring cells, which can be used to adjust for temperature changes. In humid and wet environments, both indoors and outdoors, in which conventional sensors cannot be effectively used and have a reduced service life, sensors with this design are a reliable alternative.

The sophisticated LAR-361 (Fig. 3) hydrostatic level sensor from Negele Messtechnik GmbH, which has been on the market for a number of years, differs from other measuring equipment in that the measuring system itself is hermetically sealed. This prevents gases and humidity from entering the system. In addition, the relative pressure measuring cell is still capable of providing readings in which the air pressure has been compensated for. The main difference to systems with permeable membranes is that in this unit, the atmospheric pressure is measured by a second measuring cell integrated in the sensor. This cell is hydraulically connected with the membrane of the process pressure measuring cell, which is in contact with the medium being measured (e.g., milk). The measuring cell for the atmospheric pressure (= pressure measuring cell for the ambient air pressure) conducts the measured pressure onto the rear of the process pressure measuring cell via an oil-filled tube. With the atmospheric pressure compensated for in this way, the reading is a measure of the hydrostatic pressure only, which in turn can be used to establish the filling level of the container. A further special feature is that both the process pressure measuring cell and the air pressure cell are hermetically sealed and hydraulically coupled (Fig. 4).

This design prevents the penetration of humidity into this sensitive area. Thus, the approach of this method is to solve the root of the problem rather than to correct the effects. The coupling medium consists of an FDA-approved oil filling. In addition, the pressure sensor is equipped with temperature sensors attached to the measuring cells, which can be used to adjust for temperature changes. In humid and wet environments, both indoors and outdoors, in which conventional sensors cannot be effectively used and have a reduced service life, sensors with this design are a reliable alternative.

Requirements and areas of application for pressure measuring sensors

In general, Negele level sensors can be employed for all hydrostatic level measurements and differential pressure measurements that demand high stability and a long service life. As mentioned above, there are innumerable

applications for these sensors in dairies, such as in buffer tanks, storage tanks and vats. The ambient conditions found there, namely cold products, high humidity and warm temperatures, are conducive to the formation of condensation on the sensor. Many conventional sensors adjust for the temperature at material temperatures up to around 80 °C, although accuracy is reduced at higher temperatures. Modern sensors have the capability of adjusting for temperatures up to 120 °C and can also be used at process temperatures up to 130 °C. Sensors with this innovative technology can withstand sterilization processes at temperatures up to 140 °C over a period of 30 minutes.

In general, Negele level sensors can be employed for all hydrostatic level measurements and differential pressure measurements that demand high stability and a long service life. As mentioned above, there are innumerable

applications for these sensors in dairies, such as in buffer tanks, storage tanks and vats. The ambient conditions found there, namely cold products, high humidity and warm temperatures, are conducive to the formation of condensation on the sensor. Many conventional sensors adjust for the temperature at material temperatures up to around 80 °C, although accuracy is reduced at higher temperatures. Modern sensors have the capability of adjusting for temperatures up to 120 °C and can also be used at process temperatures up to 130 °C. Sensors with this innovative technology can withstand sterilization processes at temperatures up to 140 °C over a period of 30 minutes.

Copyright © 2022 Anderson-Negele