Product Finder

Client Logo

FrieslandCampina Germany GmbH Werk Gütersloh

FrieslandCampina Germany GmbH Werk Gütersloh

Application Detail

Application

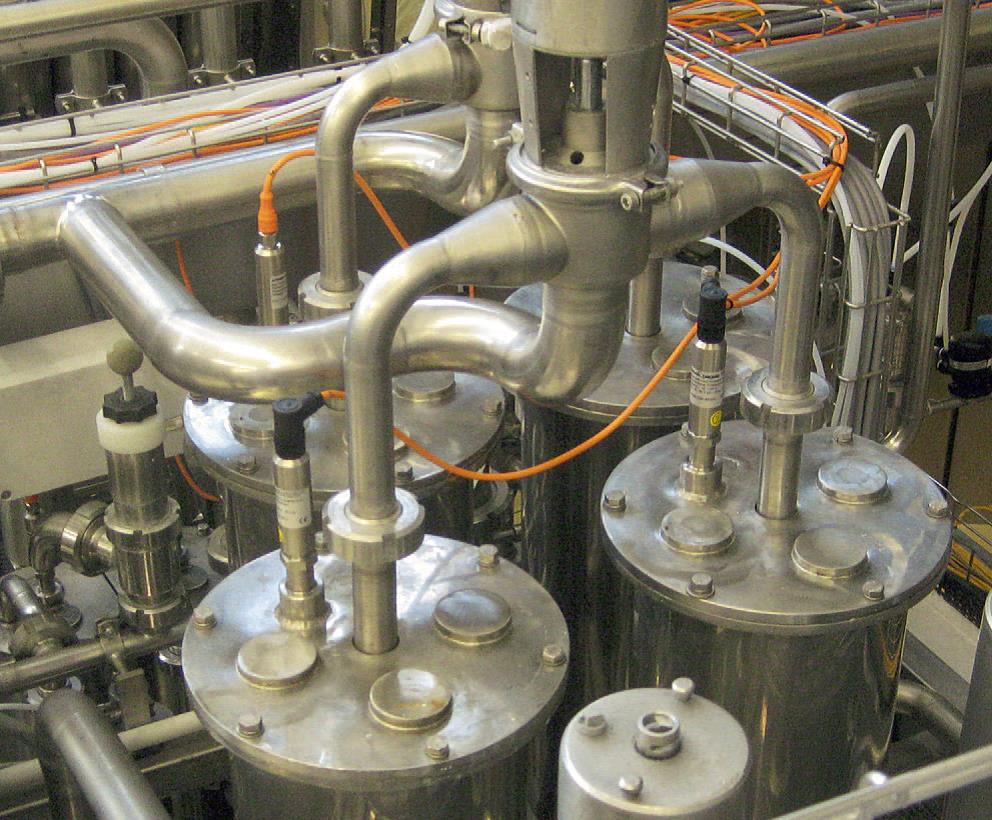

Level control in a filling system for different kinds of yogurt.

Level control in a filling system for different kinds of yogurt.

Requirement

To be able to set the product quantity, the empty, half-full and full levels need to be monitored in the pre-filler and main filler and controlled by a pump. Until now, conductive limit sensors were used to measure the three filling levels. Different kinds of yogurt as well as product adhesion to the sensor repeatedly led to false measurements. Occasionally, this caused the containers to overfill and the pump to run dry.

Anderson-Negele solution

Advantages

- Different kinds of fruit can be filled without having to create settings for each specific product.

- Instead of requiring three limit sensors as was previously the case, only one continuous level sensor with a two-wire technology is now required. This reduces procurement, installation and service costs.

- Additional dry running protection is no longer necessary.

Why the dairy decided for Anderson-Negele

- The NSL-M continuous level sensor makes it possible to control the level precisely.

- Because the filling height in the fillers is constant, the filling quantity can be set precisely and this quantity is reliably maintained.

- Different kinds of fruit can be processed without having to set the system for each individual product.

.png)

Copyright © 2022 Anderson-Negele