Product Finder

Ultrasonic Flow Measurement

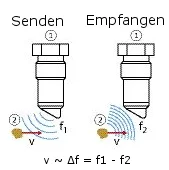

Operating principle of the ultrasonic flow measurement

By means of ultrasonic flow measurement the flowing liquids in pipes or tubes can be monitored, and in addition the flowing speed of the medium can be derived. The Ultrasonic Flow Monitor has an extremely rapid response time and works independent of temperature changes.

Copyright © 2022 Anderson-Negele