Sensores para o processo de fabricação de cerveja: Todos os fabricantes de cerveja têm a aspiração de proporcionar aos seus clientes uma experiência consistente e distinta. No entanto, também têm de assegurar o funcionamento económico bem-sucedido da empresa, otimizando permanentemente os processos, o consumo de recursos e os custos. É uma expressão da arte de fabrico de cerveja conseguir alcançar ambos em simultâneo, tendo em conta que o produto está sujeito a tantas influências e tem uma variedade tão grande como a cerveja.

A tecnologia de medição inteligente pode ajudar a garantir uma qualidade consistente do produto, mesmo com a flutuação da qualidade dos ingredientes ao longo do processo de fabrico da cerveja, a automatizar processos, a minimizar o consumo de energia e de recursos e a evitar paragens na produção. Consulte o nosso portefólio de produtos e componha a sua “tecnologia de sensores de sonho”.

Por mais diversificada que seja a qualidade da matérias-primas, das receitas e dos procedimentos no processo de fabrico de cerveja, também o são os requisitos para a tecnologia de medição. É por isso que oferecemos um programa completo de sensores, cada um com uma vasta gama de variantes e opções, para que obtenha exatamente o desempenho desejado para cada aplicação e instalação, desde a sala de brassagem até à adega de fermentação, e desde cervejarias artesanais até grandes cervejarias industriais.

A clarificação é frequentemente o ponto de estrangulamento no processo de fabrico de cerveja em termos de tempo; cada minuto poupado na clarificação aumenta a eficiência global. A análise em linha de alta precisão do mosto também ajuda a controlar a batida e assim acelerar este fator que limita o processo de fabrico de cerveja.

O filtro de placa e estrutura é uma alternativa mais rápida à tina de filtração, com requisitos adicionais de controlo de processo e tecnologia de medição para um processo de filtração sem problemas.

O objetivo é atingir a gravidade original desejada através da evaporação da água.

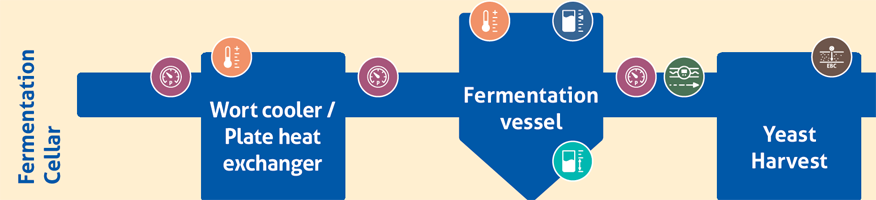

Um permutador de calor arrefece rapidamente o mosto quente. O controlo preciso da temperatura e o fluxo sem problemas tanto da cerveja verde como do meio de arrefecimento são importantes aqui.

Após a adição da levedura, a cerveja amadurece nos tanques de fermentação. Para garantir que as substâncias aromáticas e de sabor se desenvolvem da forma desejada para uma qualidade de cerveja reprodutível, as condições de fermentação devem ser mantidas com a máxima precisão. Isto inclui factores relevantes como a composição do mosto, a taxa de arejamento, a contagem de células de levedura, a estirpe de levedura, a gestão da levedura, a temperatura e a pressão. Os tanques de fermentação actuais, a maioria dos quais são fechados, devem ser monitorizados quanto à sobrepressão, para além da monitorização da própria fermentação.

Muitos tipos de levedura podem ser reutilizados várias vezes e podem ser colhidos após o processo de fermentação. Uma separação distinta da levedura morta e das diferentes qualidades de levedura reutilizável é essencial neste processo. Os sensores de turbidez podem ser configurados para direcionar automaticamente as diferentes camadas de levedura para os locais corretos.

Dependendo do tipo de cerveja, a turbidez é parcial ou totalmente filtrada da suspensão antes do armazenamento. Isto pode ser feito por filtros de terra de diatomáceas, filtros de fluxo cruzado, filtros de vela ou centrífugas / separadores.

São utilizados diferentes sistemas de enchimento para garrafas, barris e latas. Durante a limpeza das garrafas, os sensores ajudam a monitorizar a qualidade da limpeza e dos agentes de limpeza.

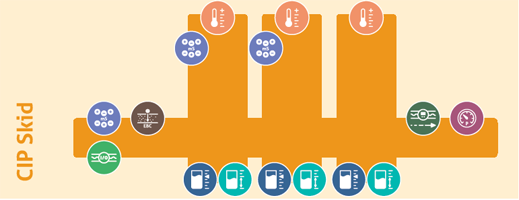

Os sistemas CIP para uma fábrica de cerveja podem ser centrais ou descentralizados. Para aumentar a eficiência, o fluxo de retorno dos meios pode ser monitorizado quanto ao grau de contaminação, recorrendo a sensores de análise. Isto permite que os produtos de limpeza dispendiosos sejam automaticamente devolvidos ao tanque de lotes quando o grau de contaminação é baixo e que a água de enxaguamento pouco contaminada possa ser reutilizada para o enxaguamento prévio no processo seguinte. Através da medição da condutividade, é possível monitorizar e controlar automaticamente a concentração do produto de limpeza. Na nossa secção “Soluções” / “Controlo CIP”, encontrará todos os detalhes sobre como a tecnologia de sensores inteligentes pode contribuir para processos CIP eficientes em termos de recursos e reprodutíveis.

O consumo de energia é influenciado pela temperatura, duração do processo e quantidade de meios. Uma ligeira variação da temperatura, seja para mais ou para menos, na adega de fermentação, pode significar custos de várias centenas de euros por ano. Se o processo de lavagem durar mais 10 minutos, há também desperdício de energia. Um processo CIP que demore mais tempo devido ao controlo do tempo, mesmo que o grau de limpeza desejado já tenha sido alcançado, também consome recursos e energia desnecessariamente. Os permutadores de calor de placas e os condensadores de vapor podem, por sua vez, ser utilizados para a recuperação de energia.

Sensores de alta precisão com saída ativa para controlo e automatização de processos podem ajudar a evitar perdas de energia e a otimizar a recuperação de energia.

A nossa dica: Examine todos os processos quanto ao seu potencial de otimização. Teremos todo o gosto em ajudá-lo no local. Basta contactar-nos.

Muitos dos nossos sensores estão disponíveis na versão “remota”. O dispositivo de medição propriamente dito e a unidade eletrónica com display de operação e transmissor estão separados. Isto protege a eletrónica de vibrações e altas temperaturas e pode aumentar significativamente a vida útil. É também extremamente prático, uma vez que pode simplesmente colocar a eletrónica e os visores onde for mais conveniente e acessível para uma leitura ou programação fácil e rápida.

A nossa dica: Obtenha a visão geral perfeita de todos os processos e recipientes sem ter de se baixar ou andar à volta e garanta uma programação fácil e uma vida útil mais longa com sensores remotos.

Muitos processos na fábrica de cerveja baseiam-se numa diferenciação de acordo com a turbidez, condutividade ou concentração. Na prática, os desvios nestes critérios não são muitas vezes fáceis de detetar. Mas são cruciais para a qualidade do produto e para a eficiência do processo. Os sensores analíticos são o seu “olho no tubo”, a sua visão dentro do processo, e podem controlar automaticamente o processo através de uma saída ativa. Isto pode substituir a amostragem manual ou as mudanças de fase com controlo de tempo.

A nossa dica: Em múltiplos processos, tais como a lavagem, a colheita de levedura, o turbilhonamento, o engarrafamento e o controlo CIP, isto permite-lhe poupar tempo de trabalho, evitar perdas de produto, reduzir a quantidade de águas residuais, garantir uma qualidade consistente e assegurar que a cerveja acaba na garrafa e a água de enxaguamento no esgoto. Basta ir à nossa secção “Soluções” / “Análise de processos” para encontrar todos os detalhes.

Os produtos Anderson-Negele são concebidos e fabricados exclusivamente para aplicações alimentares. Por isso, cumprem todos os requisitos para áreas de produção sensíveis à higiene desde o início, tal como comprovado por certificações como a 3-A e a EHEDG. Isto significa máxima proteção higiénica dos seus produtos, fácil limpeza do equipamento e, em última análise, máxima paz de espírito e prazer para os seus clientes.

A nossa dica: No que diz respeito às ligações de processo, também oferecemos uma vasta gama de soluções que asseguram a integração higiénica nas suas instalações através de um design sem espaços mortos e de materiais e superfícies de qualidade superior. Com o CLEANadapt e o FLEXadapt, desenvolvemos especialmente sistemas de conexão de processos que simplificam a instalação e operação higiénica e podem até ser adaptados.

A maioria dos sensores Anderson-Negele com IO-Link está equipada com a “Flex-Hybrid Technology”, ou seja, comunicação digital IO-Link e analógica 4…20mA em paralelo. Mesmo que a instalação seja operada de forma analógica, é possível colocar todos os sensores em funcionamento com apenas um software através do computador. A programação específica pode ser facilmente transferida para outros sensores através de copy-paste. E no caso de uma troca de sensor, toda a programação individual é transferida simplesmente conectando-o.

A nossa dica: Com a tecnologia Flex-Hybrid, já tem vantagens na instalação e colocação em funcionamento. E se mais tarde mudar para a tecnologia digital IO-Link, não há necessidade de novos sensores. Saiba tudo sobre as nossas soluções IO-Link na nossa secção “Soluções / IO-Link” ou no website IO-Link.

Muitos clientes utilizam os nossos sensores numa grande variedade de requisitos quotidianos. Descubra como outras fábricas de lacticínios ou produtores de queijo estão a ultrapassar com sucesso os seus desafios com os sensores Anderson-Negele. Os nossos estudos de caso mostram exemplos em que conseguimos ajudar os nossos clientes a atingir os seus objectivos através de consultoria de aplicações, testes de produtos ou apoio técnico. Pode encontrar os nossos estudos de caso online aqui.

A nossa dica: Os nossos estudos de caso podem dar-lhe uma pequena visão geral da variedade de aplicações em que a instrumentação inteligente, utilizada corretamente, pode facilitar o seu trabalho, melhorar a qualidade e reduzir os custos. Temos todo o gosto em encontrá-lo no local para encontrar respostas às suas questões no local. Por favor, contacte-nos!

São indispensáveis em quase todos os passos da produção de lacticínios ou de queijo e para o controlo CIP. É por isso que oferecemos os nossos sensores de temperatura em 2 padrões (Big e Mini), com uma gama de desempenho abrangente e uma variedade quase infinita de personalização, conexões de processo e opções.

Diferentes temperaturas, diferentes formas de recipientes, por vezes pressurizados, diferentes densidades, diferentes meios de espuma, diferentes teores de turvação e de sólidos – requisitos muito diferentes e alterações dinâmicas influenciam o controlo do nível de enchimento dos seus vários recipientes e contentores. No entanto, em qualquer momento é necessário saber exatamente a quantidade de produto que se encontra no recipiente ou garantir que um recipiente não transborde ou fique seco. É por isso que oferecemos diferentes técnicas de medição e muitos modelos e opções diferentes, para que obtenha a melhor solução para cada objetivo e aplicação.

Mantenha sempre um controlo ótimo da pressão do processo ou do recipiente . Graças às muitas opções de sensores, encontra sempre a solução mais adequada para cada aplicação, cada requisito e cada gama de medição de pressão pretendida, quer seja como um ecrã no local ou para ligação PLC.

Eis como manter o controlo dos seus produtos, monitorizar a sua mistura e garantir o funcionamento fiável da sua fábrica: Controlo preciso do caudal com medidores de caudal electromagnéticos. Os monitores de caudal emitem um alarme quando o caudal pára e são ideais para monitorizar sistemas de bombas, filtros, circuitos de refrigeração, o retorno CIP ou para detetar meios mal direcionados.

Os sensores de turbidez podem ser utilizados para distinguir claramente os líquidos com base na sua clareza, mas também no seu teor de gordura. Pretende salvaguardar a qualidade do seu produto através da monitorização precisa do grau de turvação? Controlar o seu separador de forma optimizada? Controlar a transição de fase do leite, natas e soro de leite com a máxima eficiência? Reutilizar meios CIP ligeiramente contaminados e assim poupar custos? Minimizar os custos de águas residuais através da monitorização da contaminação? Então os nossos sensores de turbidez são a solução perfeita.

Para uma transição de fase ativa e automatizada, controlo do retorno CIP de ácido / cáustico / água e controlo da concentração dos produtos de limpeza CIP: ILM-4, a sua garantia de fiabilidade do processo.

Para uma vasta gama de tipos de sensores, os nossos sistemas de ligação oferecem um conceito de instalação higiénico consistente: aço inoxidável de alta qualidade ou PEEK para todos os componentes molhados, ligação de parafuso simples e segura ou mesmo instalação em poços termométricos para remoção do sensor sem perturbar o processo.

Transforme o seu recipiente numa balança de precisão. Quando os sistemas integrados de controlo de nível falham, os sistemas de pesagem são os mais adequados. Os discos de carga dão-lhe controlo total do conteúdo, mesmo com recipientes intercambiáveis para ingredientes ou aditivos.

A sua chave para uma maior eficiência: sensores com IO-Link na tecnologia Flex Hybrid. Estes tornam o planeamento, a colocação em funcionamento e a operação das suas instalações mais fáceis, mais rápidos e mais flexíveis. Para as instalações analógicas existentes, Flex-Hybrid significa uma programação mais fácil, mudanças de sensores com “plug-and-play” e, se a dada altura for feita uma atualização para o controlo IO-Link, os sensores são mudados simplesmente ligando-os.

Resumimos numa brochura geral como a Anderson-Negele o pode apoiar na otimização dos seus processos de fabrico de cerveja:

Consulte o nosso portfólio de produtos e reúna a “tecnologia de sensores desejada” para a sua empresa. Aqui pode contactar-nos.

Copyright © 2022 Anderson-Negele