Foam-Insensitive level measurement with NSL-F

Dairy

The problem: Time and again, the production process for rice pudding has come to a standstill at Friesland-Campina, one of the leading manufacturers of European dairy and dessert products.

The reason: The measuring systems used in the past could not distinguish between milk-rice mix and foam. So the filling level in the supply tank was frequently not detected correctly, and the system switched off.

The consequence: Every time the entire produced quantity of a complete process batch was lost.

The solution: Since switching over to the potentiometric level sensor NSL-F more than 5 years ago, the process has been running smoothly and fully automatically, there has not been a single plant downtime since the switch was made.

Customer

Günter Stiepan, Team Manager

“We tried everything possible, but it was only with Anderson-Negele that we found a safe and reliable level measurement. This was so convincing for us that we have since been using NSL-F in other areas, such as in the fruit feed container or for dessert creams. For me, the most important criteria are process efficiency, relief for the employees, and consistently high quality through the best possible automated processes.

I see Anderson-Negele as an absolute pioneer in level, turbidity

and conductivity measurement and I count on them as a partner.”

Application Detail

The application

Friesland Campina produces rice pudding in a continuous process with a defined production volume per hour. Rice is prepared in a dosing tank and, together with pre-heated milk, is fed through a system of heaters and coolers. The production process is precisely adjusted during this process so that when the rice pudding is ready for filling at the end of the line, a precisely specified consistency is achieved.

The milk-rice mixture in the feed tank foams very strongly. The previous level sensors would often inaccurately read as“full,” although there was only foam in the container, and therefore no more milk was added. The lack of supply led to blockage and repeatedly caused a production standstill. As a result, the entire production volume could no longer be used, and besides, the cleaning and restarting caused the loss of several hours of production time.

The Anderson-Negele solution

Production manager Günter Stiepan initially only found a remedy through constant visual control and manual readjustment, until his Anderson-Negele application specialist suggested a solution: Potentiometric level measurement with an NSL-F rod probe. An in-process test immediately showed that the continuous measurement remains utterly unaffected by the foam and always indicates the rice milk mixture's correct level. After this initial test, the NSL-F stayed installed, and has been ensuring smooth operation for over 5 years now: since then, there has not been a single further production breakdown.

Further applications

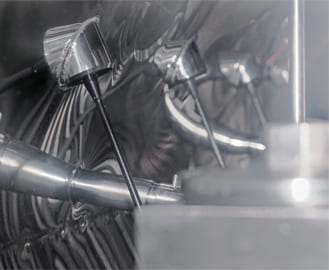

Based on the positive experiences gained, Friesland-Campina has also switched from point level measurement with LS measuring rods of different lengths to continuous level measurement with NSL-F for the dosing unit for dessert creams. For this purpose, the probe (shown on the left picture, top right in the picture) was retrofitted to the container with a weld-on socket. The four LS switches remain installed as a redundant system.

Copyright © 2022 Anderson-Negele