Application Detail

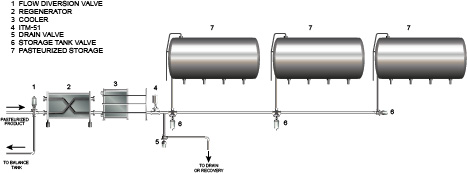

In High-Temperature Short-Time (HTST) pasteurization systems, the ITM-51 turbidity sensor plays a crucial role in detecting the transition from product to water during the water flush phase. Positioned on the discharge piping before the pasteurized storage tanks, the ITM-51 monitors turbidity levels to signal when the product-water interface has cleared the system. This ensures efficient product recovery, minimizes waste, and enables seamless automation of flow diversion to storage or drain based on real-time data.

The Application

A turbidity meter is located on the discharge piping prior to the final pasteurized storage tanks.

A turbidity meter is located on the discharge piping prior to the final pasteurized storage tanks.

The Requirements

Following a production run a pasteurization piping schematic is chased with water to recover pasteurized product to the storage tanks. A turbidity monitor gives indication that the product-water interface has finished moving through the piping schematic.

The Anderson Solution

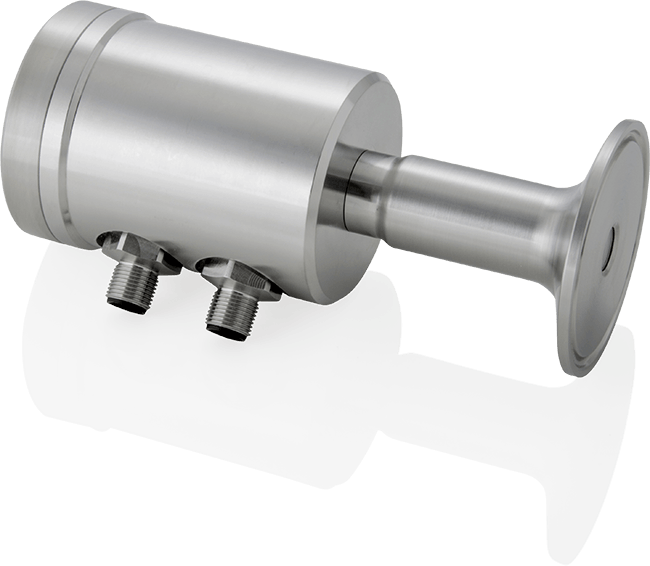

The ITM-51 is located at the discharge of an HTST processing system to continuously monitor the relative turbidity of liquid in the pipeline. When a product process run is completed a water flush is initiated on the input side of the system to push the product from the system into the pasteurized storage tanks. The ITM-51 continuously monitors the solids content of the outgoing liquid and gives an analog output signal of the relative turbidity. As the turbidity begins to decline caused by dilution with water a decision is automatically made by the control system to redirect flow from the storage tanks to drain or the waste water recovery system.

The Anderson Advantage

- Fast acting electronics offer quick response to product changes enabling predictable recovery

- LED lamp technology avoids deterioration in measurement experienced by other illumination sources providing years of trouble free service.

- Standard programmable switched and analog outputs simplify integration into plant control systems

- Extended length “L” model overcomes the difficulties of measuring transition with high viscosity product applications

- Selectable ranges increase resolution to achieve optimal trigger points for flow diversion

Copyright © 2022 Anderson-Negele