Detalhe da aplicação

A Aplicação

Os Requisitos

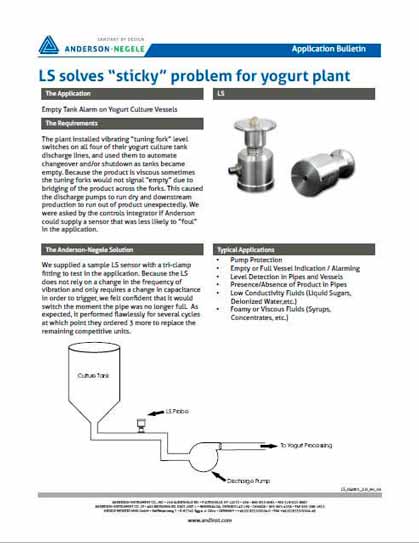

The plant installed vibrating “diapason” level switches in the four yogurt culture tank discharge lines and used them to automate changeover and/or shutdown when the tanks were empty. As the product is viscous, the tuning forks sometimes do not signal "voids" due to the product bridging between the tuning forks. This caused the discharge pumps to run dry and downstream production unexpectedly. We were asked by the controls integrator if Anderson could provide a sensor that is less likely to "smudge" the application.

A Solução Anderson-Negele

Aplicações Típicas

- pump protection

- Empty or full vessel indication / alarm

- Level detection in pipes and vessels

- Presence / absence of product in pipelines

- Low conductivity fluids (liquid sugars, deionized water, etc.)

- Foams or viscous liquids (syrups, concentrates, etc.)

Copyright © 2022 Anderson-Negele