Food, Beverage and Dairy

Life Sciences

Food, Beverage and Dairy Life Sciences

Food, Beverage and Dairy

Life Sciences

L3 Pressure and Level Transmitter

Level Sensors, CIP Control, IO-Link, Pressure Sensors

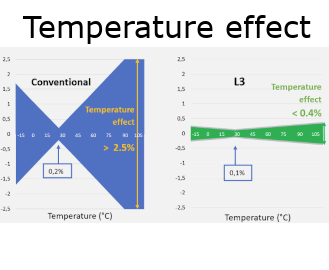

L3 Neo, the next generation of the market-proven Level and Pressure Transmitter L3, sets new standards in Level and Pressure Control. With its exceptional performance characteristics, the L3 is particularly suitable for process pressure control in critical environments, or for superior level and volume measurement. This applies specifically for smaller vessels or for high and changing process temperatures for which pressure sensors were previously not considered precise enough.

- Superior accuracy due to minimum temperature effect

- Direct output of volume, level or pressure

- Integrated tank linearization and density compensation

- New electronics and robust design for toughest productions environments

- Flex-Hybrid Technology (IO-Link + 4…20 mA in parallel)

- Life Science version available

Key Benefits:

Product Information:

Technical Specification

| Process Connection | Tri-Clamp | CLEANadapt | Anderson Flush Mount | DRD | CPM | Endress & Hauser Universal |

| Wetted material | Stainless steel, AISI 304 (1.4301), Ra ≤ 0.8 μm (32 μin) |

| Wetted material 2 | FOOD: Stainless steel, AISI 316L, Ra ≤ 0.64 μm (25 μin) PHARMA: Stainless steel, AISI 316L, Ra ≤ 0.2 μm (8 μin) |

| Measuring range | -1…35 bar Relative |

| Accuracy | ≤ 0.10% of the calibrated range |

| Available versions | Compact | Remote |

| Temperature range process | -18...110°C (0...230°F) |

| Temperature range CIP/SIP | 135°C (275°F) | max. 60 min. |

| Communication | 4…20 mA | IO-Link | HART |

| Technical Support: How to videos | Click here to view the playlist of our How to videos |

Application

Videos

L3 Advantages and Applications

L3 works underwater

Wet calibration

Change units

Tank configuration

Re-Zero

Measurement range

Product density configuration

Factory reset

Alarm / switch output

Damping change

Range setting

Download

Key Benefits:

Product Information:

User manuals:

Product Resource (Technical Information):

Software:

Process Connection

Copyright © 2022 Anderson-Negele