Surface Quality

In order to provide ideal conditions for sterile production, the surface must be smooth and non-porous down into the microscopic scale. Overlapping areas, or material laminations, must be avoided as much as possible due to the dead spaces that result, as these areas are difficult or impossible to clean and represent ideal breeding grounds for germs and bacteria.

Additionally, the dimensions (including height!) must be kept as small as possible to minimize the influences of the surfaces in contact with the product. These surfaces can be obtained by means of electropolishing.

Technologies Details

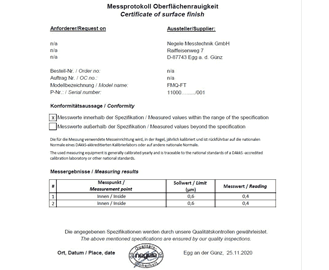

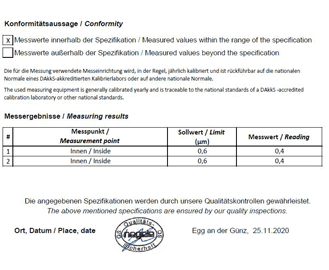

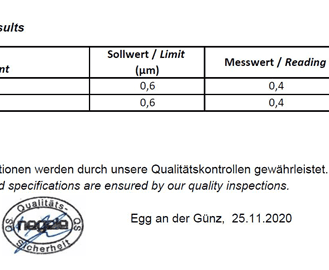

In the Life Sciences industry, and others, the quality of the surface is typically defined in terms of the “Ra”-roughness. A surface with Ra ≤ 0.8 μm is normal, in special cases also Ra ≤ 0.6 μm and even Ra ≤ 0.4 μm.

All these qualities can be achieved by appropriate machining with good quality steels and electropolishing them for a sufficiently long period of time. Ra is the mathematical average of all protuberances on the surface y over a certain measurement distance L in the x-direction.

Copyright © 2022 Anderson-Negele