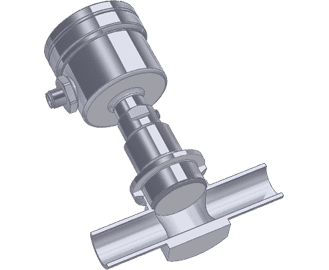

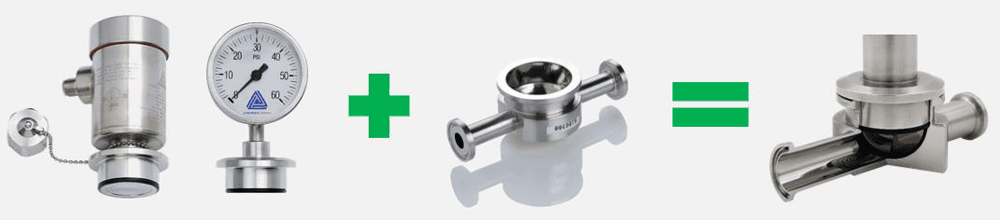

Installation system CPM: Dead space-free, front-flush installation of pressure sensors even in pipes with a small nominal diameter

For a highly accurate and hygienic pressure measurement, the pressure membrane should be integrated into the process flush with the front and free of dead spaces. However, this is a certain challenge in the case of pipes with a small nominal diameter. For pipes with a small nominal diameter, the CPM installation system offers a process connection that is easy and safe to install and offers unique advantages thanks to its special design.

Technologies Details

The special design of the CPM installation system has outstanding advantages and guarantees a process connection that can be easily and safely installed, even for pipes with a small nominal diameter.

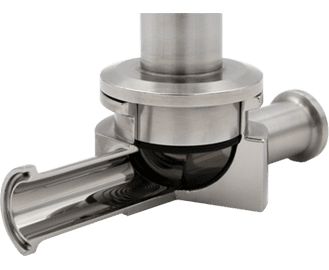

Installation without dead space with perfect membrane position

Due to the design of the CPM adapter and the extension of the sensor connector, the pressure membrane inline sits precisely at the level of the media feed-through. This enables an absolutely flow-optimized and hygienic installation situation to be achieved. Dead spaces that occur with T-pieces or weld-on sockets are excluded due to the construction of the CPM built-in system.

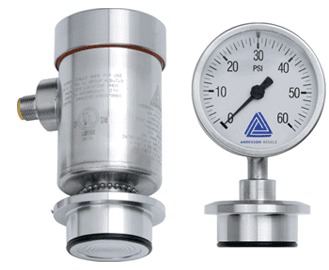

Pressure sensors with standard sizes:

Pressure sensors with standard diaphragm diameters of 22 mm or 38 mm are also used for very small pipe sizes from ¼ “. Measurement tolerances – as with smaller diaphragm diameters – are avoided in the design.

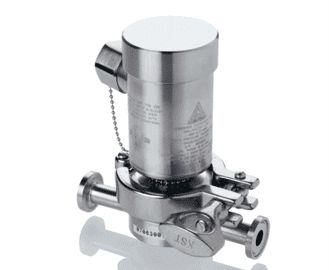

Easy installation:

The CPM adapter is either simply attached in the process with a tri-clamp clamp or welded hygienically and safely with an AWF welding collar using the orbital method. The pressure sensor used is sealed with an O-ring and mounted with a standard 1½ “clamp.

The following pressure sensors are suitable for installation in a CPM system:

You will find an overview of all process adaptation systems and the sensors suitable for them in the brochures Process adaptations food And Process adaptations Pharma.

Copyright © 2022 Anderson-Negele