BAMUL Dairy, Bengaluru

BAMUL Dairy, Bengaluru

Application Detail

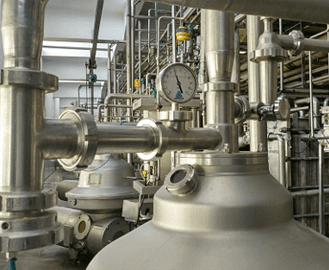

The Bangalore Urban, Rural & Ramanagara District Co-Operative Milk Producers societies Union Ltd. (BAMUL) was established 1975, and is the second largest Dairy Co-Operative in India. In the south of India, it stands first in terms of procurement and sales. NANDINI is the in-house brand for Pure and Fresh Milk and Milk Products. The Bangalore Dairy has become one of the most sophisticated Dairies in India by adopting Computer Controlled State of the Art Technology.

The Requirements

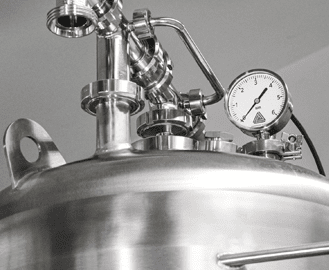

In addition, accurate pressure measurement was a critical requirement to ensure a constant milk fat ratio. To solve these problems, the manager was looking for a high quality pressure gauge that can sustain such fluctuations and help avoid any downtime, which leads to production loss.

The Anderson-Negele Solution

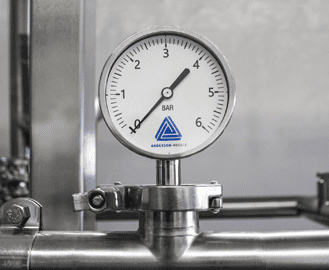

View EL Pressure Gauge

Application Advantages

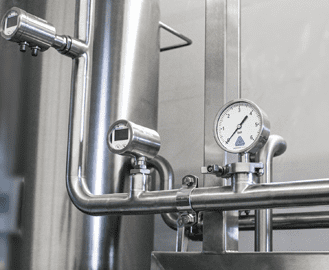

- No failures and no downtime

- High accuracy and performance even in the harshest environment

- Maintenance free as well as faster return on investment

- Higher resistance to fluctuations in the milk seperation process

Features

- Long-life Technology with wear-free mechanical system

- Extended Life "EL" Pressure gauge designed for longest durability

- Resistant to vibration, pulsation, harsh cleaning chemicals as well as humidity

- Re-zero option for calibration

- Wide process temperature range (-29 °C to 149 °C)

- Large display with 90 mm housing

- The complete device is certified by 3-A-SSI

Copyright © 2022 Anderson-Negele