State-of-the-art sensor technology for maximum fermenter process reliability

Life Sciences

In a short span of time, BPE Biotree became a leading supplier of fermenters, process vessels, CIP/SIP systems and other pharmaceutical equipment in India and many other emerging countries worldwide

This is to a great extent due to the clear focus on product quality, process dependability and professional experience which give their customers a maximum reliability for their extremely critical production processes. These criteria are also applicable for the integrated sensor technology fulfilled by Anderson-Negele. In fermenters, as an example, the sterility, yield, reproducibility and precision require the best possible temperature control and foam sensing technology along with fully hygienic certification.

Customer

Testimonials

The sensors, which respond perfectly to our precision and quality requirements, the expertise in consulting, support and reliability and customer-oriented service provided by Anderson-Negele were the decisive reasons for us to use these sensors for our process plants."

— Dr. Anil Paul Kariath, Founder of Biotree

The Anderson-Negele solution

Anderson Negele’s sensors meet the high biotree requirements with:

- extremely short response times

- highest measuring sensitivity

- no downtime due to duplex sensors

- space-saving size for compact bioprocessor design

- robust construction that withstands permanent mechanical stress, e.g. SIP processes

Application Detail

The application

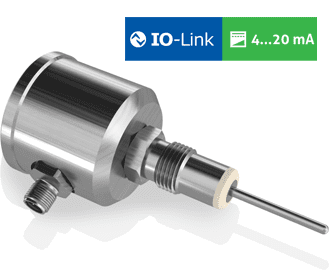

In fermenters, a highly precise adherence to the specified and often extremely narrow temperature limits is decisive for a successful fermentation process. Since a deviation from the specification can result in the total loss of valuable products, the BPE-Biotree fermenter operates in cascade between the vessel and jacket temperature control loop, supervised in highest accuracy with the temperature sensors TFP-90. The compact mini temperature sensors TFP-162P and TFP-167P are used for reliable monitoring of the SIP sequence.

During the fermentation process itself, an agitation process or air sparging can also induce foam which can cause malfunctions. The generated foam in the reactor is therefore detected by a conductive level detector of the NVS series, which can detect foam and installed at the top of the vessel.

Note: The listed sensors of the TFP product generation have been replaced by the new and more powerful sensors of the TSB and TSM (Mini) series. For all versions of the TFP sensors, the TS sensors can be configured to be fully compatible.

.png)

Copyright © 2022 Anderson-Negele